Station type bent pipe discharging and assembling device

An assembly device and station-type technology, which is applied in the field of plastic pipe processing, to achieve the effects of ensuring assembly accuracy, stable transportation, and improving blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

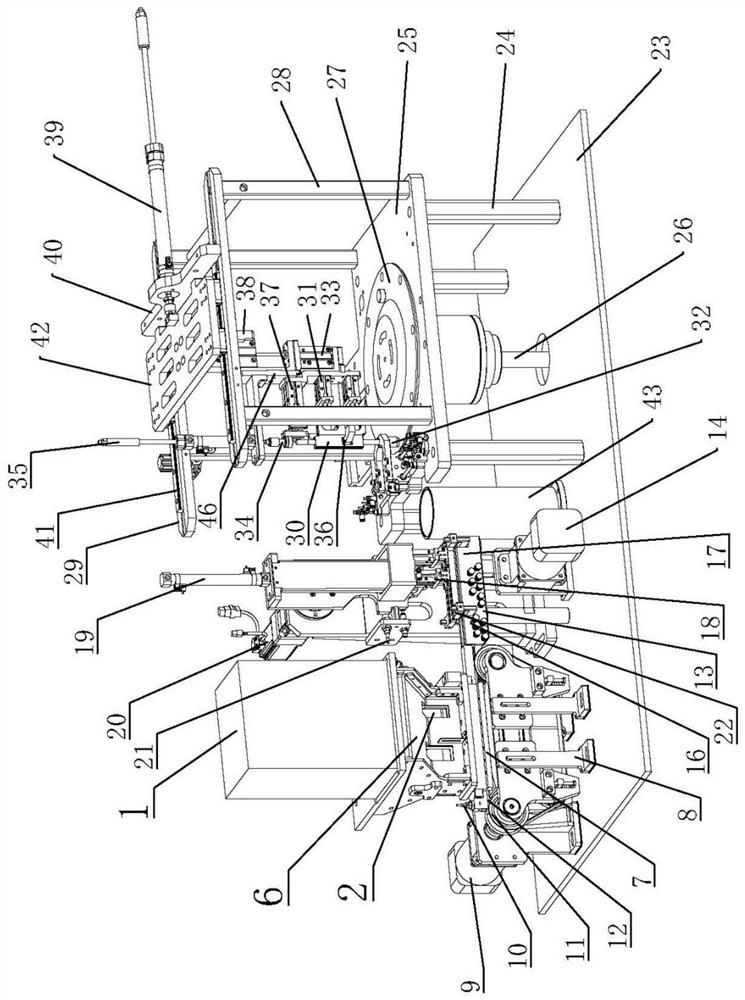

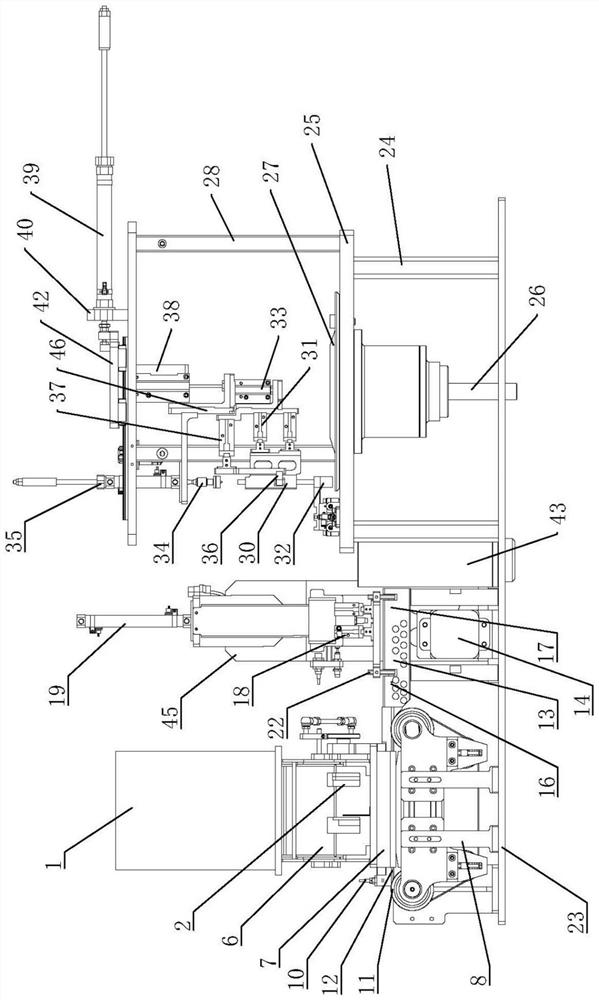

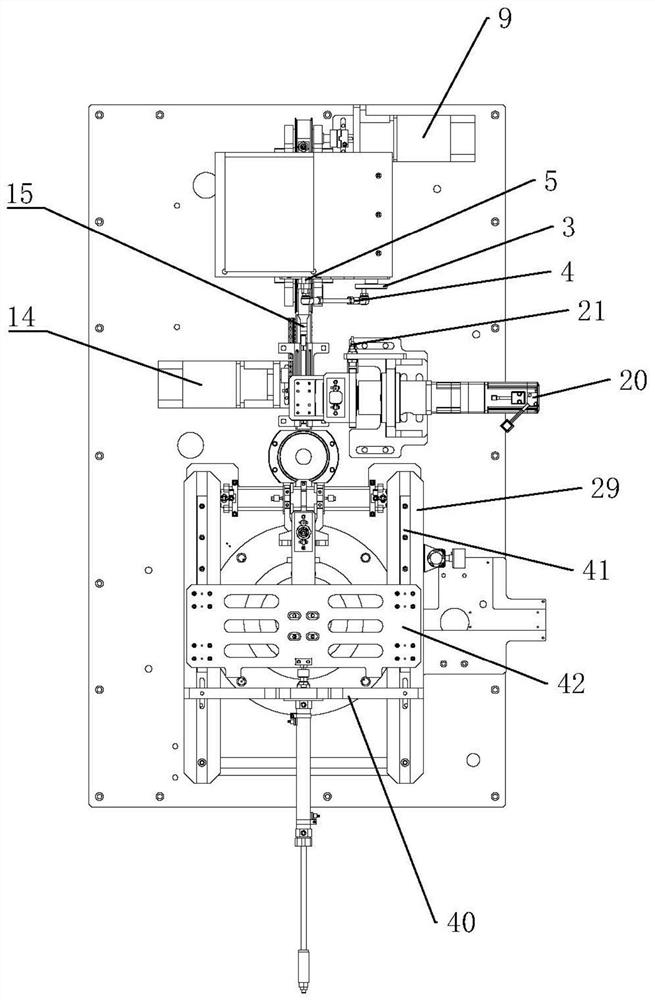

[0022] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

[0023] Such as figure 1 and figure 2 As shown, a station-type elbow blanking assembly device according to the preferred embodiment of the present invention includes a table top 23, and the table top 23 is provided with an elbow blanking assembly for blanking and an elbow feeding assembly for feeding. , the elbow retrieving assembly for feeding and the elbow assembly assembly for assembly, the elbow blanking assembly, the elbow feeding assembly, the elbow retrieving assembly and the elbow assembly assembly are arranged in sequence along the conveying direction of the plastic straw .

[0024] Such as figure 1 and figure 2 As shown, the elbow blanking assembly includes a hopper 1 for accommodating the plastic elbow to be processed. The bottom of the hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com