Processing method and processing device of semiconductor laser light homogenizing sheet

A processing method and processing device technology, applied in the direction of stone processing tools, metal processing, stone processing equipment, etc., can solve the problems of high manufacturing cost, complicated manufacturing process, and large environmental pollution of laser homogenization sheets, and achieve investment in fixed assets The effect of small size, simple processing method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

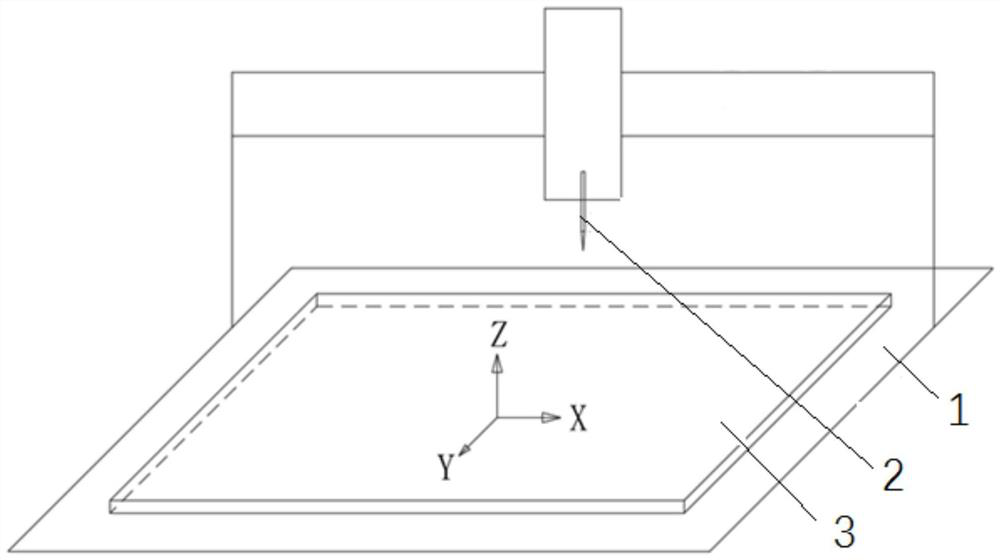

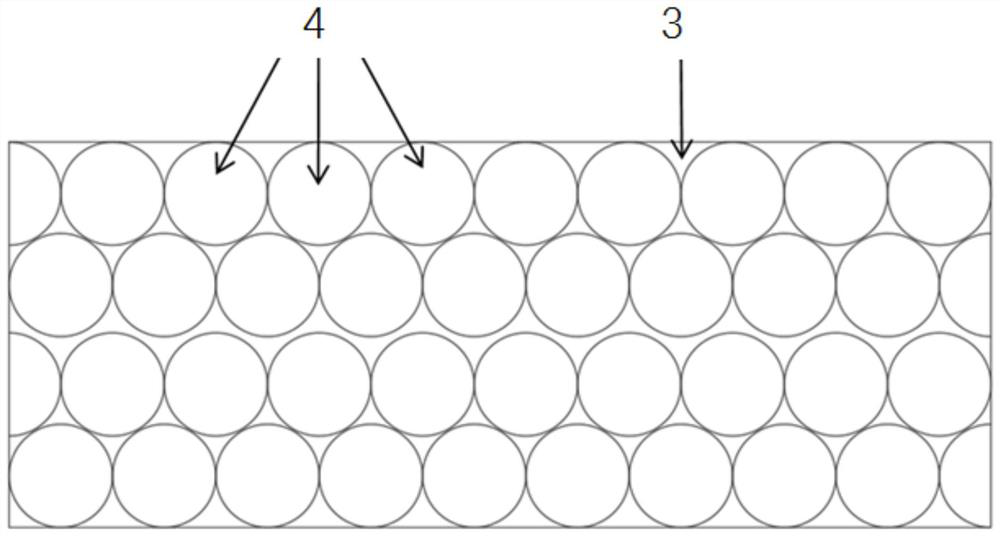

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Homogenization sheets are commonly used for the homogenization of existing lasers. However, the manufacture of traditional homogenization sheets requires complex processes such as lithography, corrosion, and cleaning. Production and manufacturing require investment in lithography, cleaning, and other equipment, which makes the input cost high. Photoresist and chemical etching, especially the waste water and waste gas produced by the corrosion process, pollute the environment, and can only etch glass, and cannot process the cheap methyl methacrylate corrosion-resistant materials. Based on the above problems, the present invention provides a processing method and a processing device for a high-power semiconductor laser light homogenization sheet. The device and method adopt a physical processing technology, the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com