Direct writing type 3D printing bio-ink and preparation method thereof

A 3D printing and bio-ink technology, applied in the field of biomedicine, can solve problems such as difficulty in maintaining its own shape, poor stability of cellulose nanofibers, and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

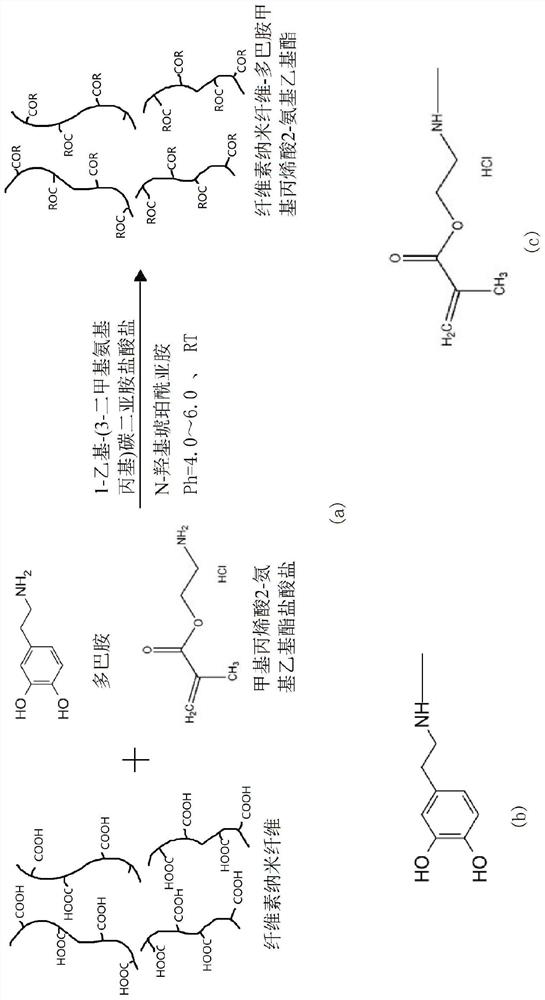

Embodiment 1

[0045] A direct-writing 3D printing bio-ink, which is composed of cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel and FBS-containing biological cell DMEM complete medium suspension, in mass percent, The proportion of cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel and FBS-containing DMEM complete medium suspension of biological cells is as follows:

[0046] Cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel 60-90%;

[0047] Biological cell DMEM complete medium resuspension containing FBS 10-40%.

[0048] Among them, the biological cells used in the resuspension of biological cell DMEM complete medium containing FBS are mouse C2C12 myoblasts or mouse MC3T3 osteoblasts, both of which were purchased from the Cell Bank of the Chinese Academy of Sciences. DMEM complete medium and FBS are commonly used reagents for cell culture medium and were purchased from Gibco, USA. It should be noted that the biological cells used in the FBS-contai...

Embodiment 2

[0060] A kind of direct writing molding 3D prints biological ink, and other features are identical with embodiment 1, and difference is: by mass percent, cellulose nanofiber-dopamine methacrylate 2-aminoethyl ester hydrogel and FBS-containing The ratio of biological cell DMEM complete medium resuspension solution is:

[0061] Cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel 70-80%;

[0062] Biological cell DMEM complete medium resuspension containing FBS 20-30%.

[0063] In terms of mass percent, the cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel contains:

[0064] Cellulose nanofiber-dopamine 2-aminoethyl methacrylate 3-7%;

[0065] LAP initiator 0.15~0.35%;

[0066] PBS buffer 92.65~96.85%.

[0067] Cellulose nanofibers, 2-aminoethyl methacrylate hydrochloride, dopamine, 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, and N-hydroxysuccinimide The mixing ratio is 1:3~7:3~7:5~17:5~17.

[0068] The direct-writing 3D printing bioi...

Embodiment 3

[0070] A kind of direct writing molding 3D prints biological ink, and other features are identical with embodiment 1, and difference is: by mass percent, cellulose nanofiber-dopamine methacrylate 2-aminoethyl ester hydrogel and FBS-containing The ratio of biological cell DMEM complete medium resuspension solution is:

[0071] Cellulose Nanofibers-Dopamine 2-Aminoethyl Methacrylate Hydrogel 60%;

[0072] Biological cell DMEM complete medium resuspension containing FBS 40%.

[0073] In terms of mass percent, the cellulose nanofiber-dopamine 2-aminoethyl methacrylate hydrogel contains:

[0074] Cellulose Nanofibers - Dopamine 2-Aminoethyl Methacrylate 1%;

[0075] LAP initiator 0.05%;

[0076] PBS buffer 98.95%.

[0077] Cellulose nanofibers, 2-aminoethyl methacrylate hydrochloride, dopamine, 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, and N-hydroxysuccinimide The mixing ratio is 1:1:1:2:2.

[0078] The direct-writing 3D printing bioink uses cellulose nanofib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com