Preparation method and application of ginger-flavor plant cigarette material

A technology of cigarette materials and plant materials, applied in the field of preparation of ginger-flavored plant cigarette materials, to meet the psychological needs of plant aroma, the production process is feasible, and the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

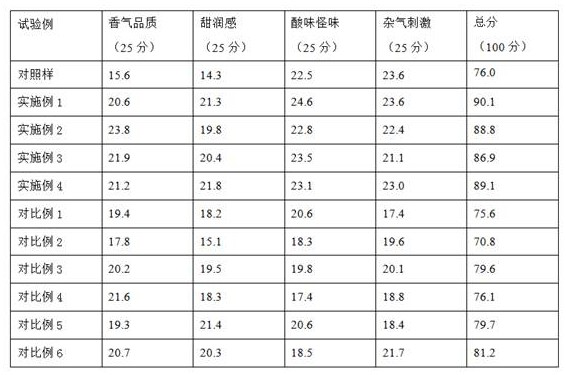

Examples

Embodiment 1

[0029] A preparation method of ginger-flavored plant cigarette material, the steps are:

[0030] (1) Weigh 500g of Luoping yellow ginger rhizome, add 6 times of water and extract for 60 minutes at a temperature of 80°C, and obtain ginger rhizome extract and ginger rhizome solid residue after solid-liquid separation; weigh Luoping small yellow ginger stem and leaf 1000g, add 8 times of water and extract for 60min at a temperature of 80°C, and obtain ginger stem and leaf extract and ginger stem and leaf solid residue after solid-liquid separation;

[0031] (2) Grinding (beating) the ginger rhizome solid residue obtained in (1), the beating degree is 40︒SR, and obtaining the ginger rhizome slurry;

[0032] (3) Grinding (beating) the solid residue of ginger stems and leaves obtained in (1), the degree of beating is 50︒SR, and obtaining ginger stems and leaves slurry;

[0033] (4) Get 200g of ginger rhizome slurry, 600g of ginger stem and leaf slurry, 100g of coniferous wood pulp ...

Embodiment 2

[0037] A preparation method of ginger-flavored plant cigarette material, the steps are:

[0038] (1) Weigh 1000g of Luoping turmeric rhizome, add 6 times of water and extract for 60 minutes at a temperature of 80°C, and obtain ginger rhizome extract and ginger rhizome solid residue after solid-liquid separation;

[0039] Weigh 1000g of Luoping turmeric stems and leaves, add 8 times of water and extract for 60 minutes at a temperature of 80°C, and obtain ginger stems and leaves extract and ginger stems and leaves solid residue after solid-liquid separation;

[0040] (2) Grind (beat) 1 / 2 of the solid residue of ginger rhizomes obtained in (1), the degree of beating is 40︒SR, to obtain ginger rhizome slurry, and dry the rest until the moisture content is about 12% Carry out pulverizing afterward, cross 40 mesh sieves and obtain ginger rhizome particle;

[0041] (3) Grinding (beating) the solid residue of ginger stems and leaves in (1), the degree of beating is 50︒SR, to obtain g...

Embodiment 3

[0046] A preparation method of ginger-flavored plant cigarette material, the steps are:

[0047] (1) Weigh 500g of Luoping turmeric rhizome, add 6 times of 75% ethanol, reflux and extract at a temperature of 80°C for 60 minutes, and obtain ginger rhizome extract and ginger rhizome solid residue after solid-liquid separation;

[0048] Weigh 1000g of the stem and leaf of Luoping yellow ginger, add 8 times of 75% ethanol to extract for 30min at 80°C, and obtain the extract of ginger stem and leaf and the solid residue of ginger stem and leaf after solid-liquid separation;

[0049] (2) Grinding (beating) the rhizome solid residue obtained in (1), the degree of beating is 30︒SR, to obtain ginger rhizome slurry;

[0050] (3) Grinding (beating) the solid residue of ginger stems and leaves in (1), the degree of beating is 30︒SR, to obtain ginger stems and leaves slurry;

[0051] (4) Get 100g of ginger rhizome slurry, 700g of ginger stem and leaf slurry, 100g of coniferous wood pulp f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com