Method for improving recession of large blind hole

A blind hole and laser drilling technology, which is applied in the direction of plating, coating, electrical components, etc. of superimposed layers, can solve the problems of increased difficulty in line etching, too thin copper layer, and pull-off of blind holes, etc., to achieve improved The effect of producing product quality, ensuring the uniformity of copper thickness, and reducing the height of surface copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The method for improving the depression of large blind holes of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

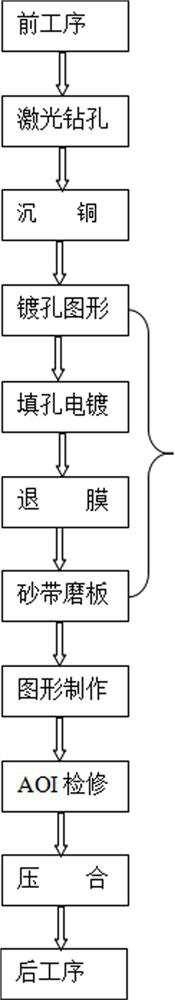

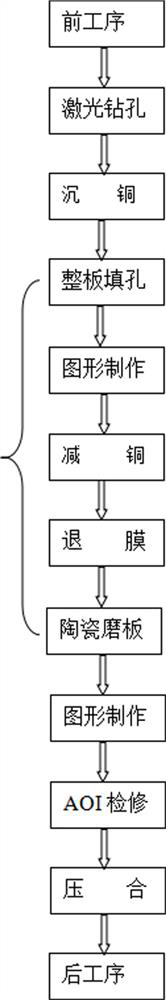

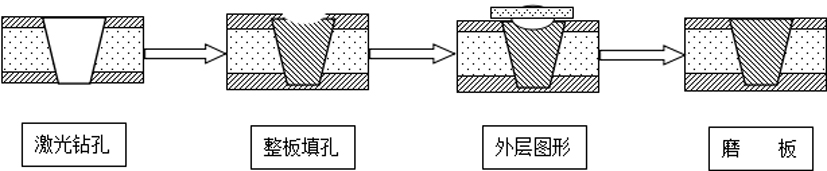

[0033] refer to figure 2 and image 3 , a non-limiting embodiment of the present invention, a method for improving the depression of large blind holes, the method is used for the filling of large blind holes with a blind hole diameter of anylayer in the inner layer ≥ 5mil, and the method is laser drilling and After electroless copper plating, the drilled big blind holes are filled and leveled by the whole board electroplating method, and then the copper surface at the big blind holes is polished and smoothed by the method of outer layer graphics, copper reduction + grinding plate in order to improve the big blind holes. method of hole depression. Specifically, the following steps are included,

[0034] S1: Electroless copper deposition. Before the electroless copper depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com