A method for online monitoring of flange bolt tension and working load

A technology of working load and flange bolts, applied in the direction of measuring force, measuring device, electromagnetic measuring device, etc., can solve the problems of bolt friction coefficient variation, high cost, damage of resistance strain gauge, etc., to improve measurement accuracy, accurate evaluation, The effect of all-round online high-precision monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

[0053] refer to Figure 1 to Figure 3 , the invention provides a method for online monitoring of flange bolt tension and working load, comprising the following steps:

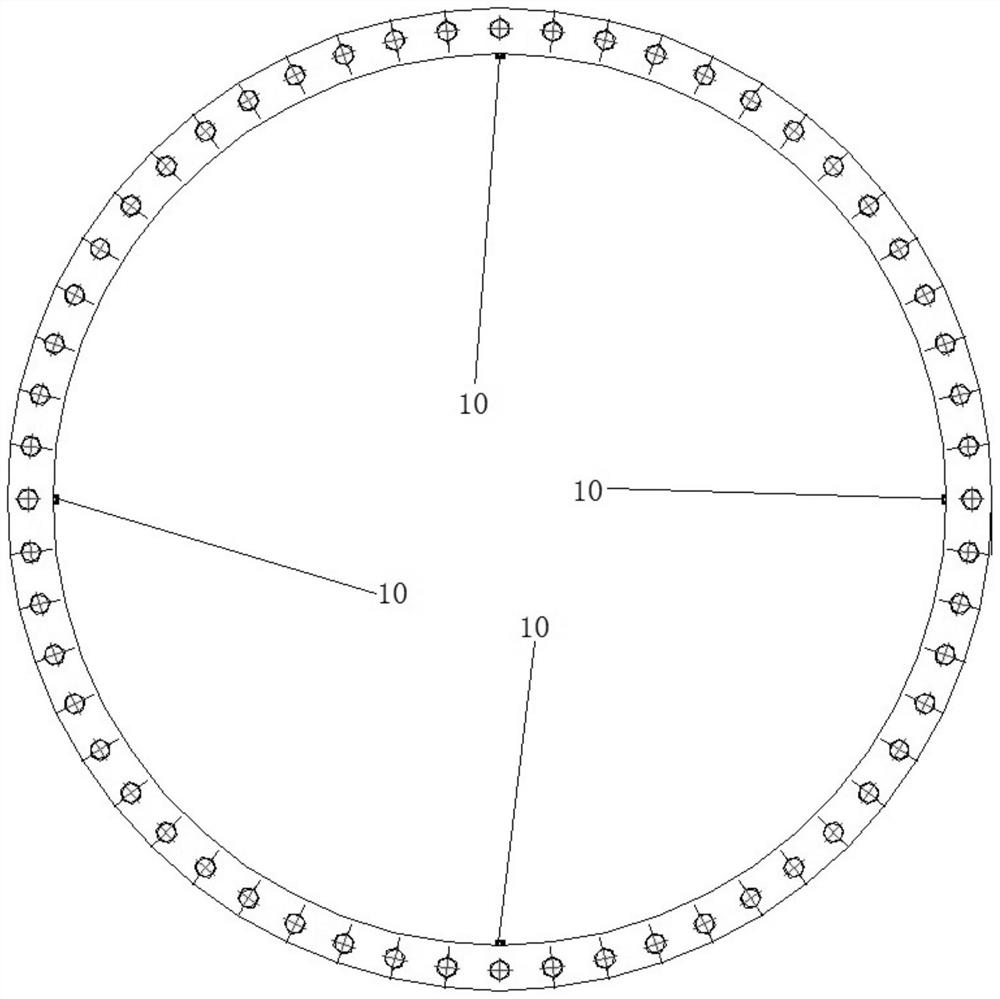

[0054] (1) Install the high-precision displacement sensor 10 evenly on the inner or outer circumference of the flange connection, and fix the spacer and the sensor body separated from each other in the high-precision displacement sensor to the two interconnected flanges respectively on the plate;

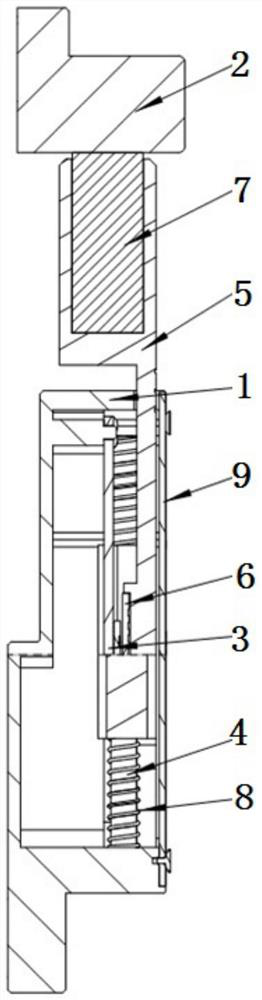

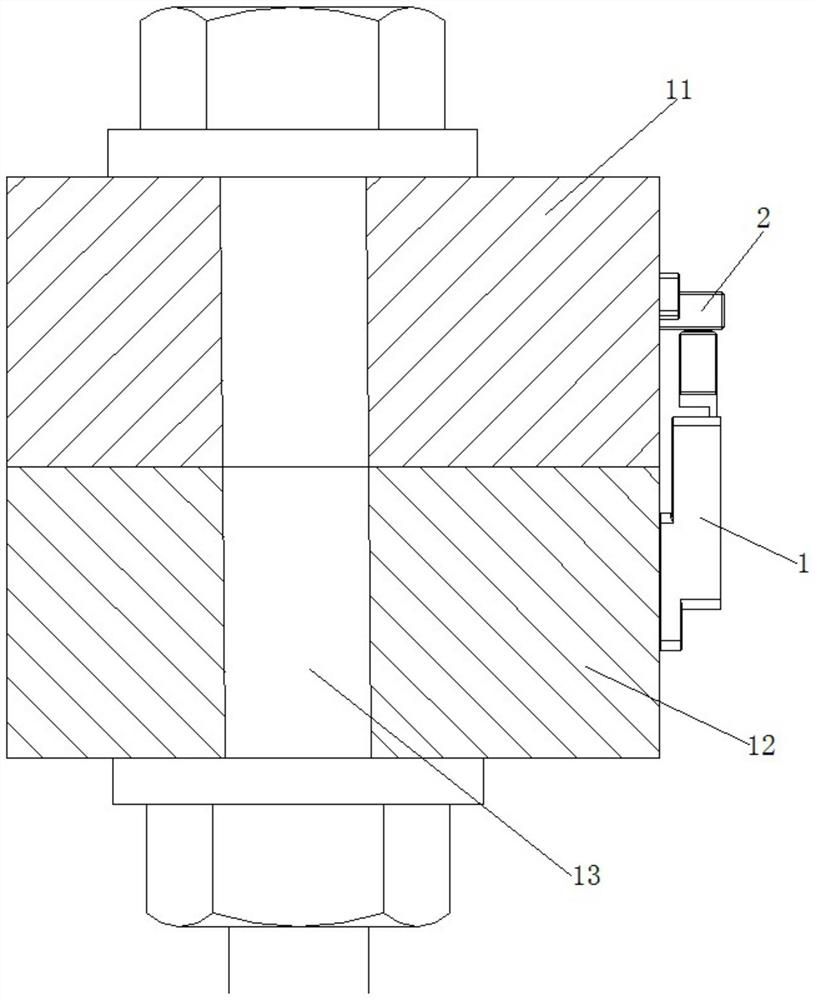

[0055] The high-precision displacement sensor used in this embodiment is composed of a spacer block 2 and a sensor body that are separated from each other, wherein the spacer block and the sensor body are respectively fixed on two interconnected upper flanges 11 and lower flanges 12. The flange connecting bolt 13 connects and fixes the upper flange 11 and the lower flange 12. The sensor body includes a housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com