A high-precision displacement sensor for gap monitoring

A displacement sensor, high-precision technology, applied in the field of displacement sensors, can solve the problems of low accuracy, poor environmental adaptability, and intermittent installation, and achieve the effect of overcoming unevenness and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

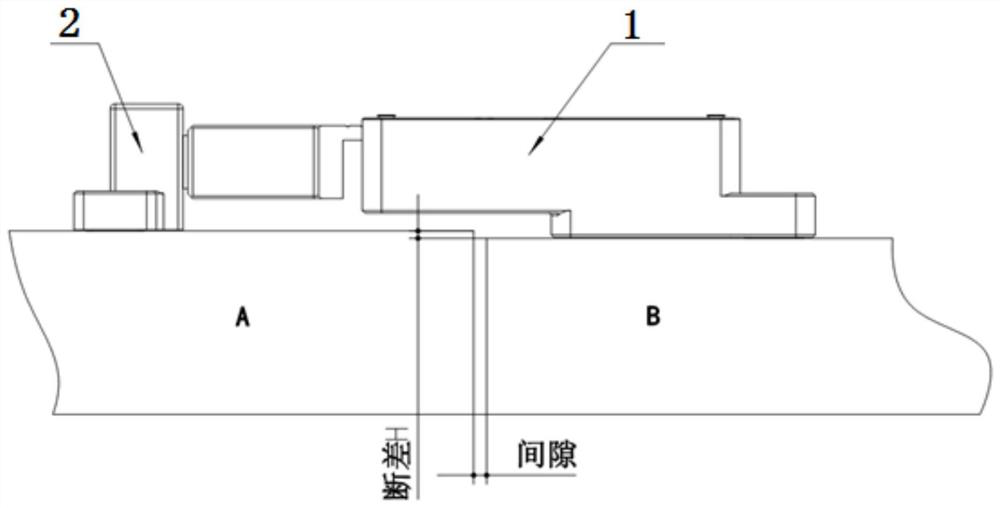

[0019] In the high-precision displacement sensor used for gap monitoring provided in this embodiment, the housing 1 and the limit block 2 are respectively fixed on the parts on both sides of the gap, such as figure 1 As shown, the two sides of the gap are part A and part B, and there is a section height difference between them.

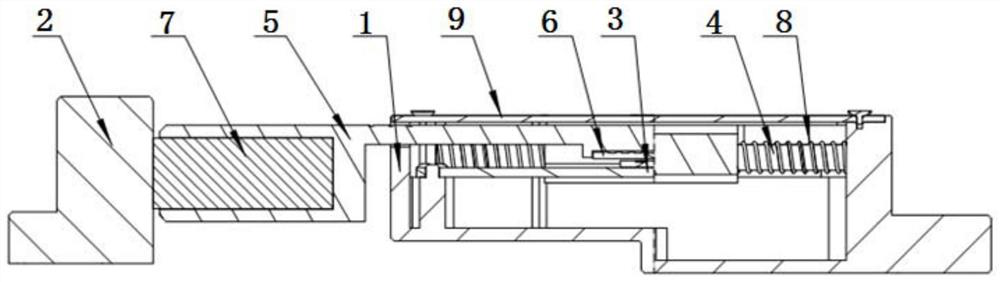

[0020] The structural section of the high-precision displacement sensor used for gap monitoring provided by this embodiment is as follows figure 2 As shown, an opening is provided on the top surface of the housing, and a cover plate 9 is provided at the opening. The housing and the cover plate are made of stainless steel, and the overall design is a metal shell. At the same time, an anti-electromagnetic interference circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com