Multi-tube type efficient energy-saving environment-friendly boiler

A high-efficiency, energy-saving, multi-tube technology, used in lighting and heating equipment, fluid heaters, etc., can solve the problems of increased load, weak injection force, scattered airflow, etc., to achieve the effect of strengthening stability and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

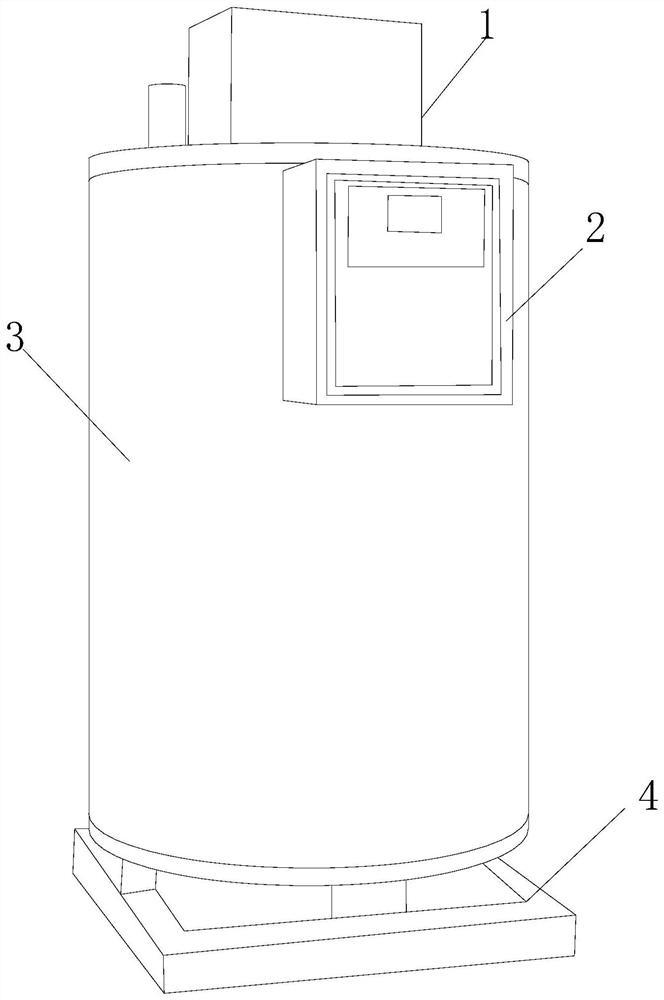

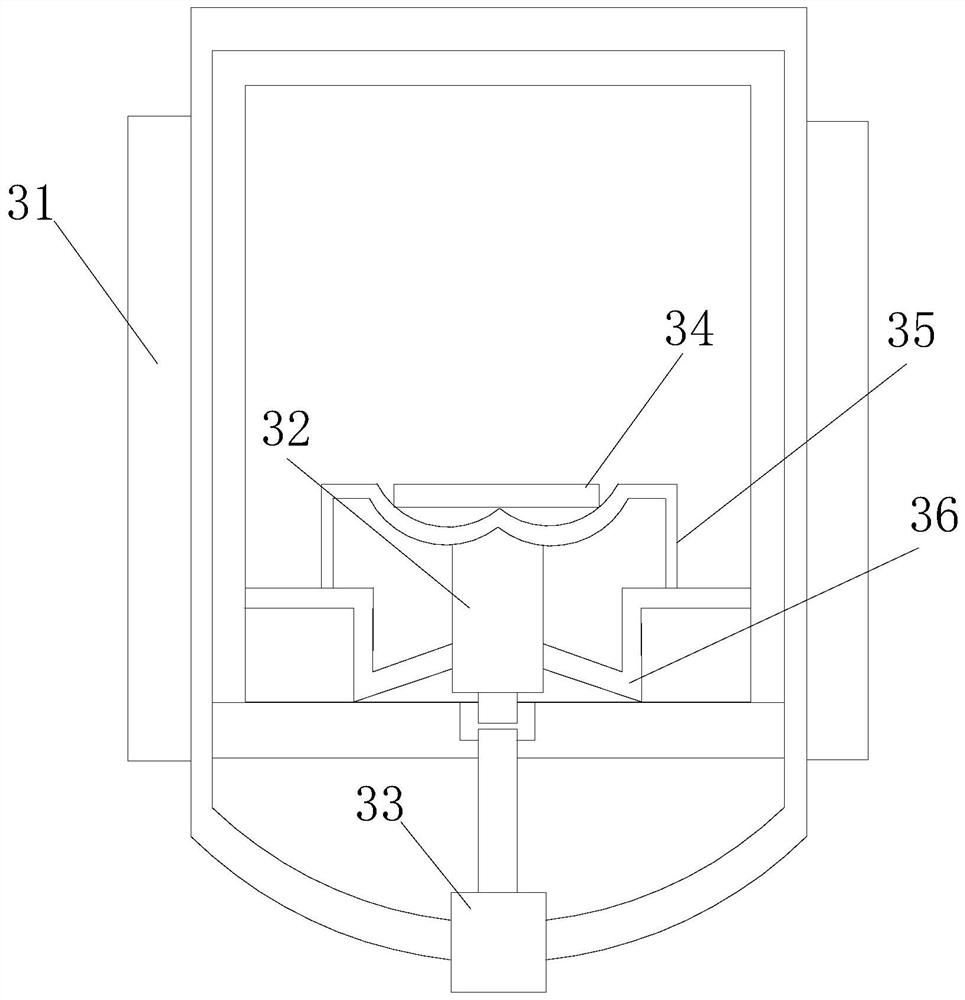

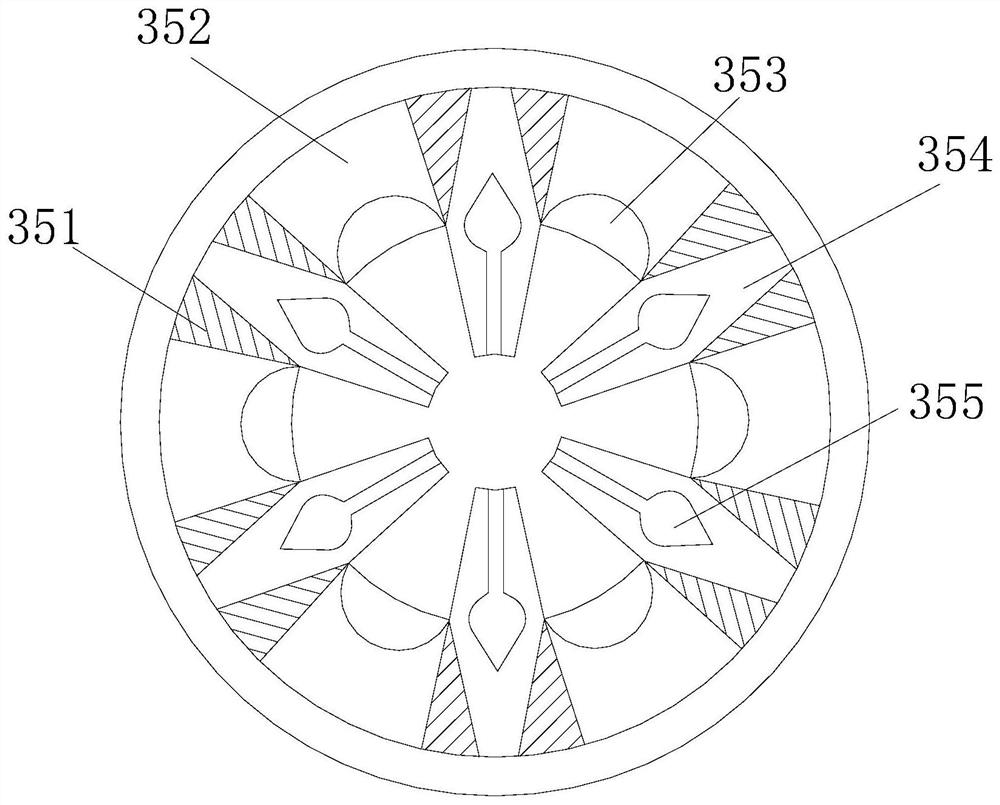

[0030] like Figure 1-Figure 3 As shown, the present invention provides a multi-tube type high-efficiency energy-saving and environment-friendly boiler, its structure includes a motor 1, a keyboard box 2, a host 3, and a frame 4, and the keyboard box 2 is electrically connected with the host 3 through the motor 1, so that The bottom of the main engine 3 is welded and connected with a frame 4. The main engine 3 includes a flue 31, a flame guide 32, a driver 33, a nozzle 34, an auxiliary structure 35, and a docking device 36. The bottom of the flue 31 is fixedly connected with a drive 33, one end of the driver 33 is buckled and connected to one end of the flame guide 32, the outside of the flame guide 32 is provided with an auxiliary structure 35 and a docking device 36, and communicates with the nozzle 34 through the auxiliary structure 35, the auxiliary structure 35 includes a reinforcing piece 351, a top plate 352, a lower pressing piece 353, a pressing piece 354, and a retra...

Embodiment 2

[0032] like Figure 4-Figure 6As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The docking device 36 includes a stabilizing structure 361, a booster 362, a stabilizing device 363, a base 364, and a top frame 365. The outer circumference of the flame guide 32 is provided with three stabilizing structures 361 with the same structure and size, a stabilizing device 363 is installed between the stabilizing structures 361, and a base 364 is fixedly connected to the bottom of the stabilizing structures 361, and the outer surface of the base 364 covers A booster 362 is provided, and the two ends of the booster 362 are fixedly connected with a top frame 365. The stabilizing structure 361 includes a guide device 1a1, a connecting column 1a2, a running-in ball 1a3, and a supporting plate 1a4. The connecting column 1a2 is installed Between the guiding device 1a1 and the supporting plate 1a4, the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com