Polyurethane insulation board for house building construction and preparation method thereof

A polyurethane thermal insulation board, polyurethane technology, applied in the direction of thermal insulation, construction, building components, etc., can solve the problems of veneer falling off, poor stability, poor stability of veneer panels, etc., to achieve the effect of improving stability, increasing contact area, and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a polyurethane thermal insulation board for house construction, characterized in that: the polyurethane core board 1 includes the following manufacturing method:

[0043] S1: Preparation of materials:

[0044]S11: prepare by weighing component A and component B according to a certain ratio;

[0045] S2: Mixing work of materials:

[0046] S21: Pour component A and component B into the mixing device according to a certain ratio, add a certain amount of water, and then start the mixing device, so that the mixing and stirring mechanism in the mixing device can work, so that it is convenient to mix the components of group A The sub-materials are mixed with the B-component materials;

[0047] S21: After mixing for a period of time, various phosphorus, chlorine, boron and other compounds added to the material of component A are used as flame retardant substances, especially the mixture of these flame retardant substances, so that the material is flame ...

Embodiment 1

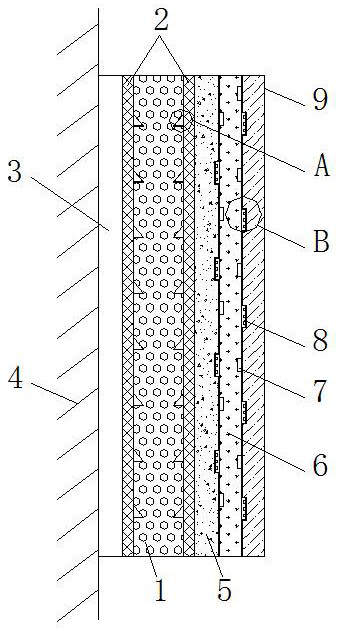

[0060] A polyurethane insulation board for house construction, comprising a polyurethane core board 1, an adhesive layer 3 and a wall body 4.

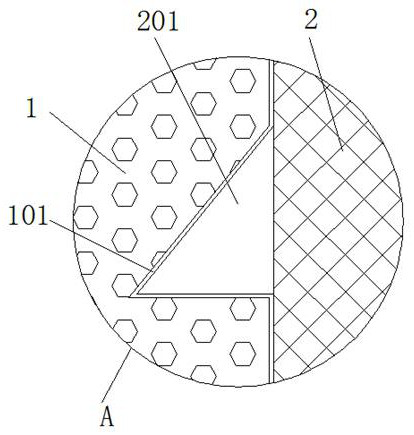

[0061] In this embodiment, the left and right sides of the polyurethane core board 1 are provided with fitting grooves 101, and the fitting grooves 101 are arranged in a right-angled triangle shape, and the depth of the fitting grooves 101 is smaller than the thickness of the connecting plate 2. A connection block 201 is engaged and mounted inside the engaging groove 101 .

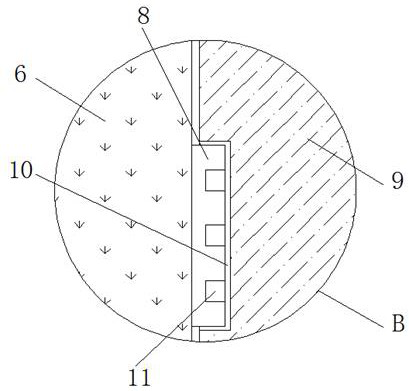

[0062] In this embodiment, protrusions 8 are integrally fixed on the left and right sides of the receiving plate 6 , and grooves 7 are formed inside the left and right sides of the receiving plate 6 , and circular holes 11 are formed inside the protrusions 8 .

[0063] In this embodiment, a receiving groove 10 is defined on the left side of the veneer 9 , and the inside of the receiving groove 10 is fitted with a protruding block 8 , and the protruding block 8 and ...

Embodiment 2

[0082] A polyurethane insulation board for house construction, comprising a polyurethane core board 1, an adhesive layer 3 and a wall body 4.

[0083] In this embodiment, the left and right sides of the polyurethane core board 1 are provided with fitting grooves 101, and the fitting grooves 101 are arranged in a right-angled triangle shape, and the depth of the fitting grooves 101 is smaller than the thickness of the connecting plate 2. A connection block 201 is engaged and mounted inside the engaging groove 101 .

[0084] In this embodiment, protrusions 8 are integrally fixed on the left and right sides of the receiving plate 6 , and grooves 7 are formed inside the left and right sides of the receiving plate 6 , and round holes 11 are opened inside the protrusions 8 .

[0085] In this embodiment, a receiving groove 10 is defined on the left side of the veneer 9 , and the inside of the receiving groove 10 is fitted with a protruding block 8 , and the protruding block 8 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap