Continuous production method for synthesizing hydrofluoroether

A production method and technology of hydrofluoroether, which is applied in the field of synthesizing hydrofluoroether, can solve the problems of long time-consuming synthesis process and high energy consumption, and achieve the effects of reducing equipment investment and floor space, increasing reaction speed, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

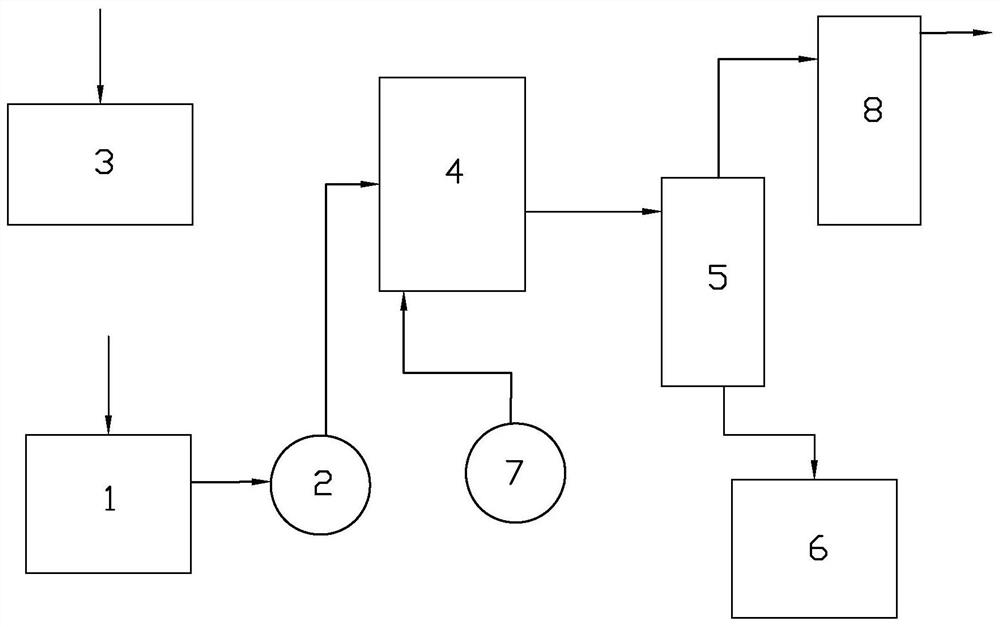

[0029] Alcohol and catalyst are prepared in proportion and loaded into the raw material tank (1) for subsequent use. Fluorine-containing olefins are fed into the fluorine-containing olefin buffer tank (3) for standby use. Then the alcohol, catalyst and fluorine-containing olefin are passed through the reaction tank (4) filled with the reaction solution of the flowmeter, the regulating valve and the first metering pump (2) according to the molar ratio of 1:0.1:1, and the residence time is controlled. In 4h, the reaction temperature was controlled at about 75°C, and then the reaction liquid was released from the bottom of the reaction kettle at the same time. The reaction solution enters the thin-film evaporator (5) for gas-liquid-solid three-phase separation. A cylinder is added inside the thin-film evaporator, wherein the upper part of the cylinder is a solid vertical cylinder, and the lower part is a metal sintered filterable inclined cylinder. The reaction liquid realizes I...

Embodiment 2

[0031] The basic steps are the same as in Example 1. The molar ratio of trifluoroethanol, potassium hydroxide, and tetrafluoroethylene is controlled to be 1:0.1:0.95, the residence time is controlled to be 1 h, and the temperature is controlled to be 50°C. After a continuous period of time, the reaction liquid was sampled and analyzed by chromatography, and the solvent peak was removed. The conversion rate of trifluoroethanol was 92.3%, and the selectivity was 99.1%.

Embodiment 3

[0033] The basic steps are the same as in Example 1, the molar ratio of methanol, potassium hydroxide and tetrafluoroethylene is controlled to be 1:0.1:1.1, the residence time is controlled to be 2h, and the temperature is controlled to be 100°C. After a continuous period of time, the reaction liquid was sampled and analyzed by chromatography, and the solvent peak was removed. The conversion rate of methanol was 92.8%, and the selectivity was 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com