A kind of recycled lightweight aggregate permeable concrete and its preparation method

A permeable concrete and lightweight aggregate technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of poor purification efficiency and stability, inability to adsorb charged ions, and small powder eddy current, so as to improve adsorption efficiency and maintain Convenience and efficiency of deicing, and the effect of increasing flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

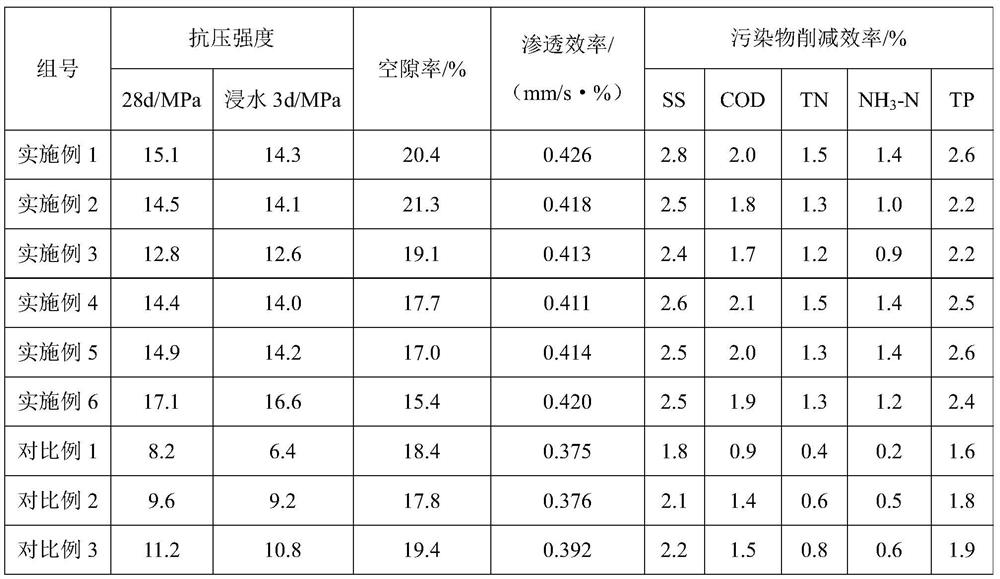

Examples

Embodiment 1

[0058] A recycled lightweight aggregate permeable concrete, the proportion is as follows:

[0059] According to the parts by weight of each raw material, 350 parts of cement, 20 parts of steel slag powder, 10 parts of limestone powder, 800 parts of modified recycled lightweight aggregate, 1000 parts of magnetic aggregate, 1 part of modified plant fine powder, 100 parts of water, 1 part of water reducer, 5 parts of plant fiber, 20 parts of magnetostrictive fiber, and 15 parts of graphene oxide.

Embodiment 2

[0061] A recycled lightweight aggregate permeable concrete, the proportion is as follows:

[0062] According to the parts by weight of each raw material, 350 parts of cement, 20 parts of steel slag powder, 10 parts of limestone powder, 900 parts of modified recycled lightweight aggregate, 750 parts of magnetic aggregate, 1 part of modified plant fine powder, 100 parts of water, 1 part of water reducer, 5 parts of plant fiber, 15 parts of magnetostrictive fiber, and 15 parts of graphene oxide.

Embodiment 3

[0064] A recycled lightweight aggregate permeable concrete, the proportion is as follows:

[0065] According to the parts by weight of each raw material, 350 parts of cement, 20 parts of steel slag powder, 10 parts of limestone powder, 1000 parts of modified recycled lightweight aggregate, 500 parts of magnetic aggregate, 1 part of modified plant fine powder, 100 parts of water, 1 part of water reducer, 5 parts of plant fiber, 10 parts of magnetostrictive fiber, and 15 parts of graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com