Ultra-high strength steel in-situ wire-powder composition-adjustable composite additive device

An in-situ, silk powder technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of uneven alloy composition, uneven powder, not considering powder mixing, etc., to achieve controllable rate, Improve the effect of poor heat dissipation and controllable heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

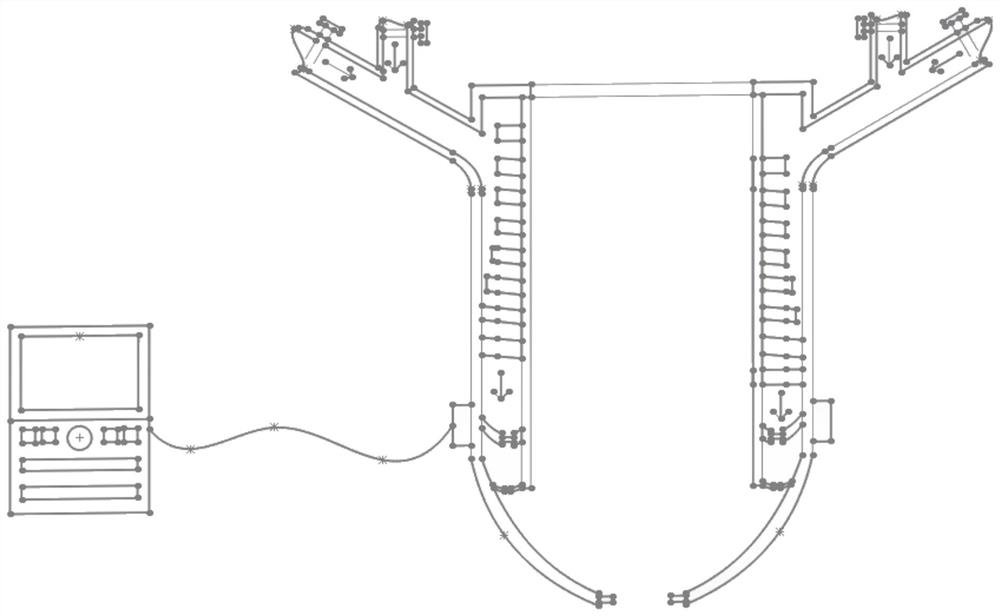

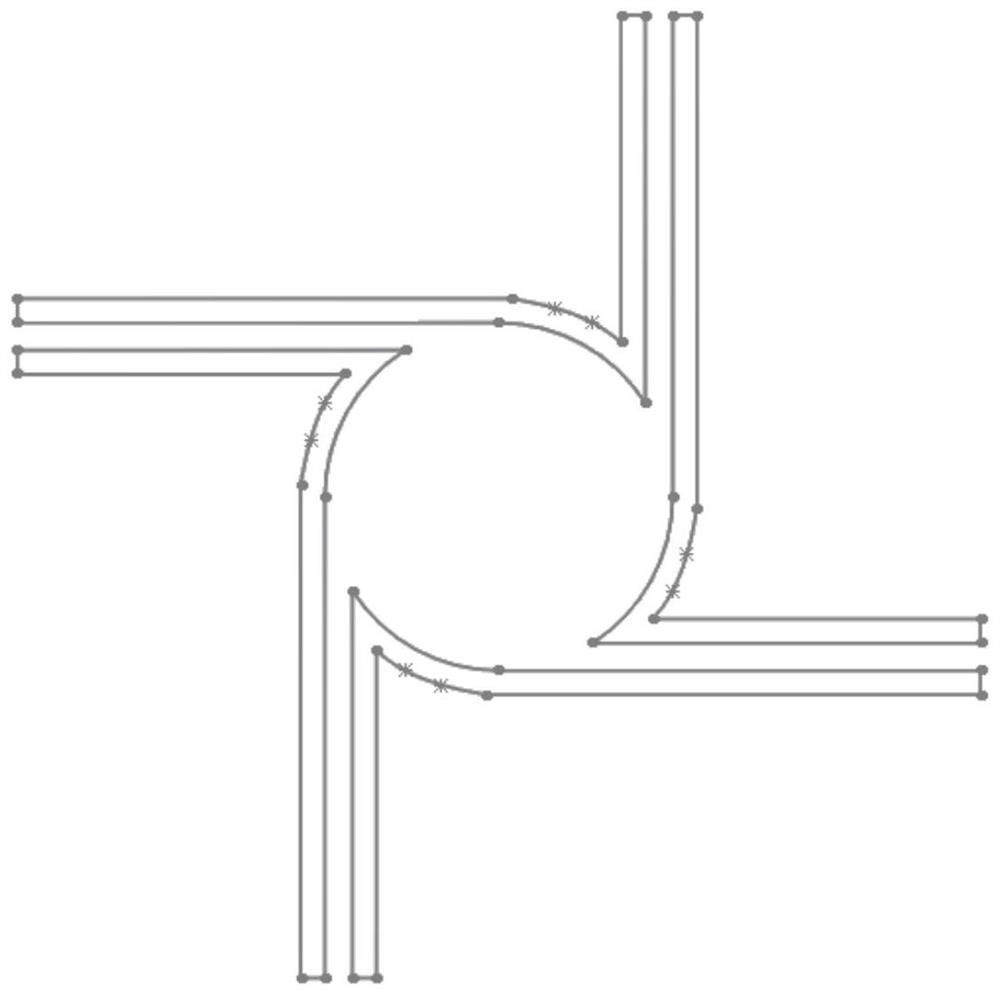

[0051] A composite additive device with adjustable in-situ wire powder composition for super-strength steel according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] The present invention includes the process of evenly regulating the composition of multi-element alloy materials and the technical method of the in-situ wire powder alloying process of adding materials, wherein the process of uniformly regulating the composition is designed in the gun body and adopts the compound mode of vibration and airflow to realize various predetermined Quantitative opening of alloy powder, deceleration screw mixing powder, sieving and uniform mixing, and uniform powder sending out of the gun body; the additive in-situ wire powder alloying process is driven by vibration and airflow compound powder feeding and plasma flow force, and the predetermined alloy The uniformly mixed powder is recombined with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com