Method and device for removing impurities of tobacco leaves in pre-processing stage of threshing and redrying

A technology of threshing and redrying and pretreatment, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large floor area, low screening efficiency, and effective separation of fragments, and achieve low crushing of tobacco leaves and high efficiency of impurity removal Thorough and efficient removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

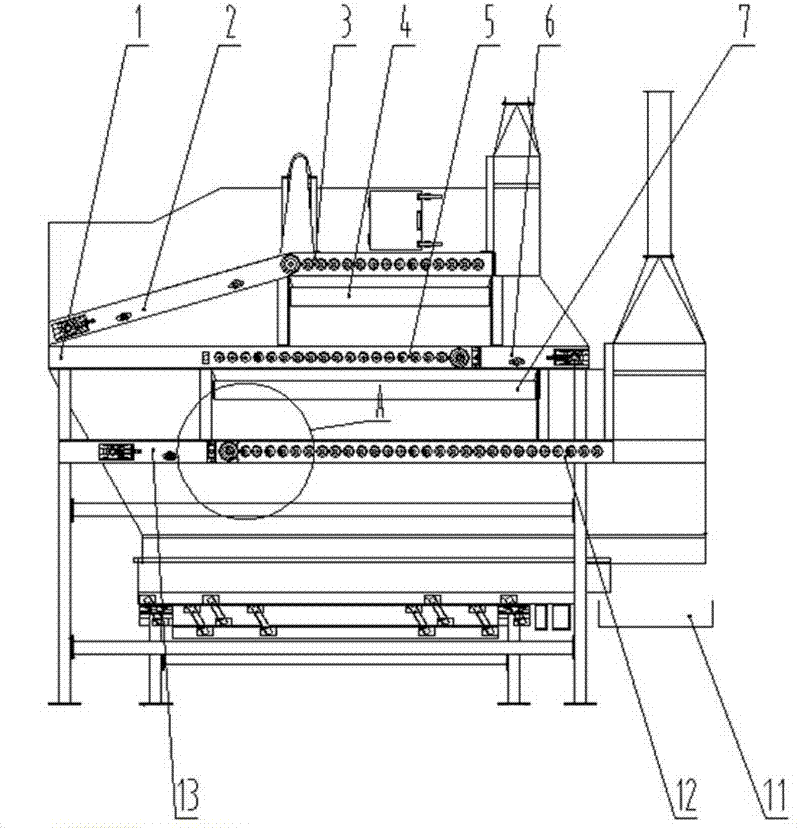

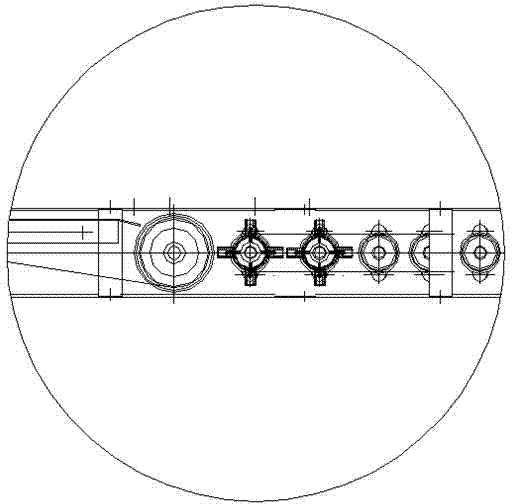

[0015] Such as figure 1 , figure 2 As shown, a device for removing impurities in tobacco leaves in the pretreatment stage of threshing and re-baking, including a frame 1, a bottom screening roller conveying device 12 installed on the frame and with staggered and opposite conveying directions, and a middle screening roller conveying The device 5 and the top screening roller conveying device 3 are arranged at the bottom of the top screening roller conveying device 3 and the top impurity collection belt conveyor 4 whose conveying direction is perpendicular to the top screening roller conveying device is arranged on the middle screening roller The middle layer impurity collection belt conveyor 7 at the bottom of the conveyor device 5 and the conveying direction is the same as the top layer impurity collection belt conveyor 4, the feed belt conveyor 2 connected to the feeding end of the top layer screening roller conveyor device 3, and the middle layer screening roller table The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com