Preparation method and application of Pd-Fe/Fe3O4 material

A ferric chloride and carrier technology, applied in the field of environmental protection and environmental restoration, can solve the problems of large grain size, low degradation efficiency and low activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

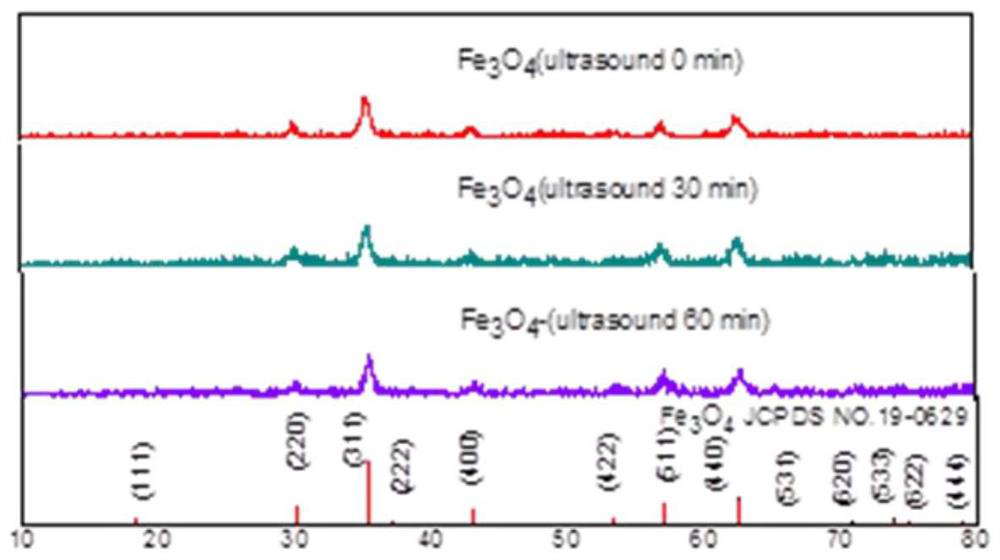

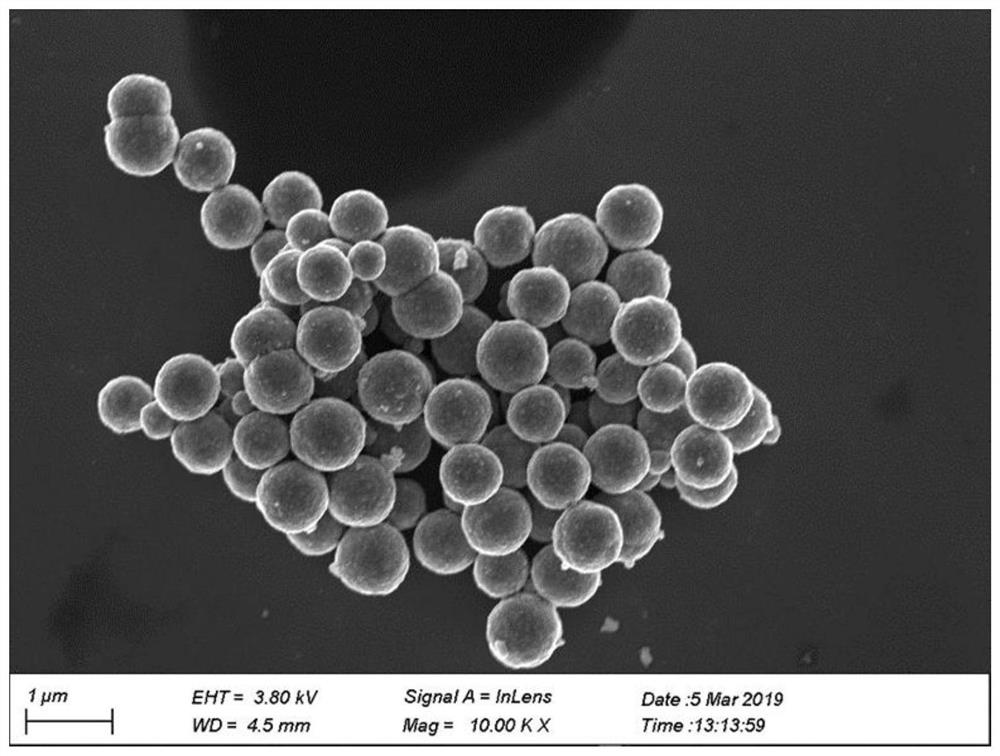

[0030] Weigh 4.0g of ferric chloride hexahydrate and 0.238g of disodium ethylenediaminetetraacetate, and dissolve them in 140mL of ethylene glycol; after stirring for 30min, add 4.2g of anhydrous sodium acetate at one time, and continue stirring for 60min; transfer the mixture Put it into a 200mL reaction kettle, react at 200°C for 10h; centrifuge to separate the product, wash the product and dry it under vacuum at 40°C to obtain Fe 3 o 4 carrier. Its XRD spectrum is as figure 1 As shown, the field emission scanning electron microscope (FE-SEM) picture is as follows figure 2 shown. It can be seen that the Fe prepared in Example 1 3 o 4 The carrier is a sphere with rough surface and relatively uniform size, and the average diameter of the sphere is about 748nm.

Embodiment 2

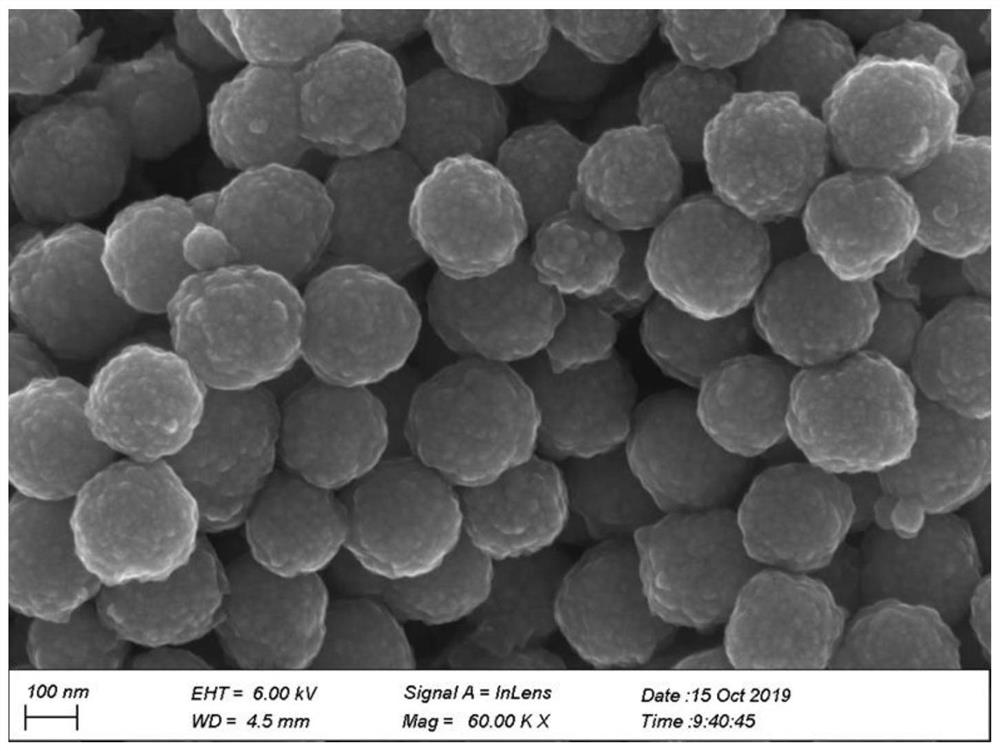

[0032] The preparation steps of this example are basically the same as those of Example 1, except that the treatment method after adding anhydrous sodium acetate is changed to stirring for 10 minutes, followed by ultrasonic treatment for 30 minutes. Its XRD spectrum is as figure 1 As shown, the field emission scanning electron microscope (FE-SEM) picture is as follows image 3 shown. It can be seen that the Fe prepared in Example 2 3 o 4 The carrier is a sphere with a rough surface and a relatively uniform size. The average diameter of the sphere is about 230 nm, and its dispersibility is obviously better than that of the material prepared without ultrasonic treatment in Example 1.

Embodiment 3

[0034] The preparation steps of this example are basically the same as those of Example 1, except that the treatment method after adding anhydrous sodium acetate is changed to stirring for 10 minutes, followed by ultrasonic treatment for 60 minutes. Its XRD spectrum is as figure 1 As shown, the field emission scanning electron microscope (FE-SEM) picture is as follows image 3 shown. It can be seen that the Fe prepared in Example 3 3 o 4 The carrier mainly appears as a rough surface sphere with an average diameter of about 296 nm. In addition to regular spheres, there are also some non-uniform particles that do not form spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com