Preparation method of corrosion-resistant environment-friendly coating

An environmentally friendly coating and corrosion-resistant technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor compatibility with methylphenyl silicone rubber, and achieve stable product quality and excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

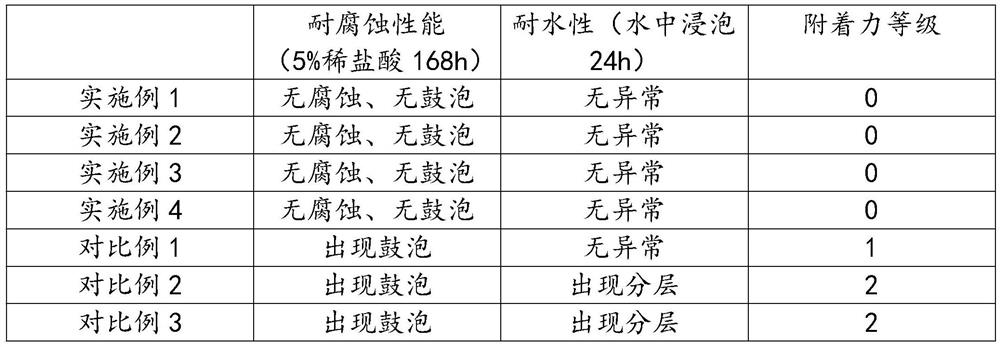

Examples

Embodiment 1

[0028] A preparation method for corrosion-resistant environmental protection paint, comprising the steps of:

[0029] The first step is to weigh the following raw materials in parts by weight: 55 parts of modified silicone, 25 parts of environmentally friendly emulsion, 8 parts of nanofillers, 1 part of polyvinylpyrrolidone, 0.5 parts of magnesium stearate, and 55 parts of absolute ethanol;

[0030] Step 2: Add modified silicone, environmentally friendly emulsion and magnesium stearate into absolute ethanol, heat in a water bath at 40°C, stir for 30 minutes, transfer to a dispersion tank and heat up to 60°C, at this temperature, use 500r / min Disperse at a rotating speed for 45 minutes to obtain a mixed solution;

[0031] The third step is to add nano fillers to the mixed solution prepared in the second step, disperse for 30 minutes at a speed of 160r / min, add polyvinylpyrrolidone, continue to disperse for 1h, transfer to a ball mill, and ball mill for 3h at a speed of 400r / min...

Embodiment 2

[0041] A preparation method for corrosion-resistant environmental protection paint, comprising the steps of:

[0042] The first step is to weigh the following raw materials in parts by weight: 60 parts of modified silicone, 26 parts of environmental protection emulsion, 10 parts of nano filler, 2 parts of polyvinylpyrrolidone, 1.8 parts of magnesium stearate, 56 parts of absolute ethanol;

[0043] Step 2: Add modified silicone, environmentally friendly emulsion and magnesium stearate into absolute ethanol, heat in a water bath at 40°C, stir for 30 minutes, transfer to a dispersion tank and heat up to 60°C, at this temperature, use 500r / min Disperse at a rotating speed for 45 minutes to obtain a mixed solution;

[0044] The third step is to add nano fillers to the mixed solution prepared in the second step, disperse for 30 minutes at a speed of 160r / min, add polyvinylpyrrolidone, continue to disperse for 1h, transfer to a ball mill, and ball mill for 3h at a speed of 400r / min, ...

Embodiment 3

[0054] A preparation method for corrosion-resistant environmental protection paint, comprising the steps of:

[0055] The first step is to weigh the following raw materials in parts by weight: 65 parts of modified silicone, 28 parts of environmental protection emulsion, 14 parts of nano filler, 2 parts of polyvinylpyrrolidone, 1.2 parts of magnesium stearate, 58 parts of absolute ethanol;

[0056] Step 2: Add modified silicone, environmentally friendly emulsion and magnesium stearate into absolute ethanol, heat in a water bath at 40°C, stir for 30 minutes, transfer to a dispersion tank and heat up to 60°C, at this temperature, use 500r / min Disperse at a rotating speed for 45 minutes to obtain a mixed solution;

[0057] The third step is to add nano fillers to the mixed solution prepared in the second step, disperse for 30 minutes at a speed of 160r / min, add polyvinylpyrrolidone, continue to disperse for 1h, transfer to a ball mill, and ball mill for 3h at a speed of 400r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com