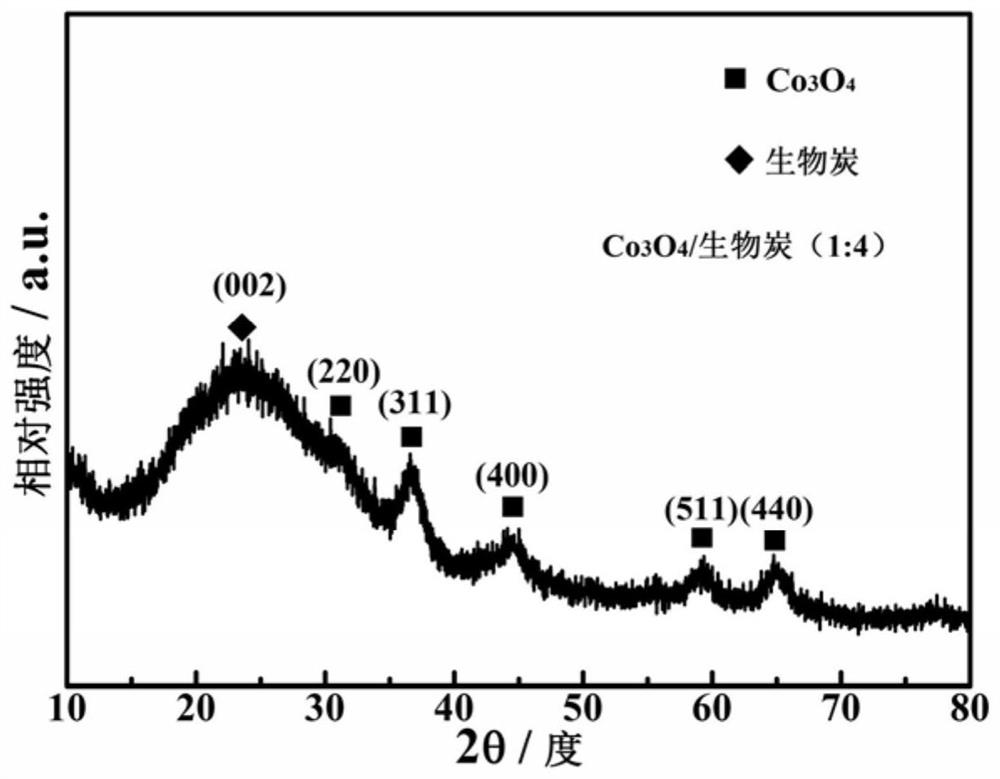

Agricultural straw biochar loaded nano Co3O4 composite catalyst and preparation method thereof

A composite catalyst, straw biotechnology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low catalytic efficiency, secondary pollution, unstable environment and other problems, to achieve the effect of large specific surface area, reducing leaching and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One aspect of the present invention provides an agricultural straw biochar loaded nano Co 3 o 4 The preparation method of composite catalyst, the method comprises the steps:

[0030] S1: cleaning, drying, crushing and sieving agricultural straw to obtain straw powder, calcining and cooling the straw powder to obtain primary biochar powder;

[0031] S2: Grinding the primary biochar powder and mixing with KOH aqueous solution, stirring and drying to obtain a mixture of primary biochar and KOH; calcining, cooling, washing, and vacuum drying the mixture of primary biochar and KOH , to obtain a high surface area activated biochar with a porous structure;

[0032] S3: Mix the high surface area activated biochar with a porous structure and ethanol to obtain a suspension, and mix the suspension with CoCl 2 ·6H 2 O and NH 4 HCO 3 mixing and stirring, washing and drying to obtain a biochar composite catalyst precursor;

[0033] S4: Grinding, calcining, and cooling the bioc...

Embodiment 1

[0062] This embodiment provides an agricultural straw biochar loaded nano Co 3 o 4 The preparation method of composite catalyst, the method comprises the steps:

[0063] S1: Rinse the rape stalks with tap water, remove the dust on the surface of the rape stalks, dry them in a blast drying oven at 120°C, crush them with a grinder, and sieve them to obtain straw powder with a particle size of less than 200 mesh. 6 g of the straw powder was loaded into a square porcelain boat, then placed in a tube furnace, and calcined at 700° C. for 2 hours under an argon atmosphere, with a heating rate of 5° C. / min. After the tube furnace was naturally cooled to room temperature, the product was taken out to obtain black primary biochar powder.

[0064] S2: After grinding 0.5 g of the black primary biochar powder obtained in step S1, add it to an aqueous solution of KOH, and ultrasonically disperse it for 1 hour to obtain a uniformly dispersed aqueous solution of primary biochar and KOH, and...

Embodiment 2-4

[0068] Embodiments 2-4 respectively provide a kind of agricultural straw biochar loaded nano Co 3 o 4 The preparation method of composite catalyst, the step of described method is identical with embodiment 1, and difference is, changed CoCl in the step S3 of embodiment 2-4 2 ·6H 2 O and NH 4 HCO 3 added amount. The CoCl of said embodiment 1-4 2 ·6H 2 O and NH 4 HCO 3 The addition amount, and the agricultural stalk biochar loaded nanometer Co that embodiment 1-4 obtains 3 o 4 Co in the composite catalyst 3 o 4 The theoretical mass ratios to rapeseed biochar are listed in Table 1.

[0069] Table 1

[0070] CoCl 2 ·6H 2 o

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com