Connecting system of fabricated combined pier and bearing platform and construction method of connecting system

A connection system and assembly technology, applied in the construction parts of railways or bridges, and roads, can solve the problems of high construction accuracy and grouting quality requirements, difficult detection of sleeve grouting compactness, and increase the cost of pier columns. The effect of component transportation and production efficiency, simplifying construction operation procedures, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

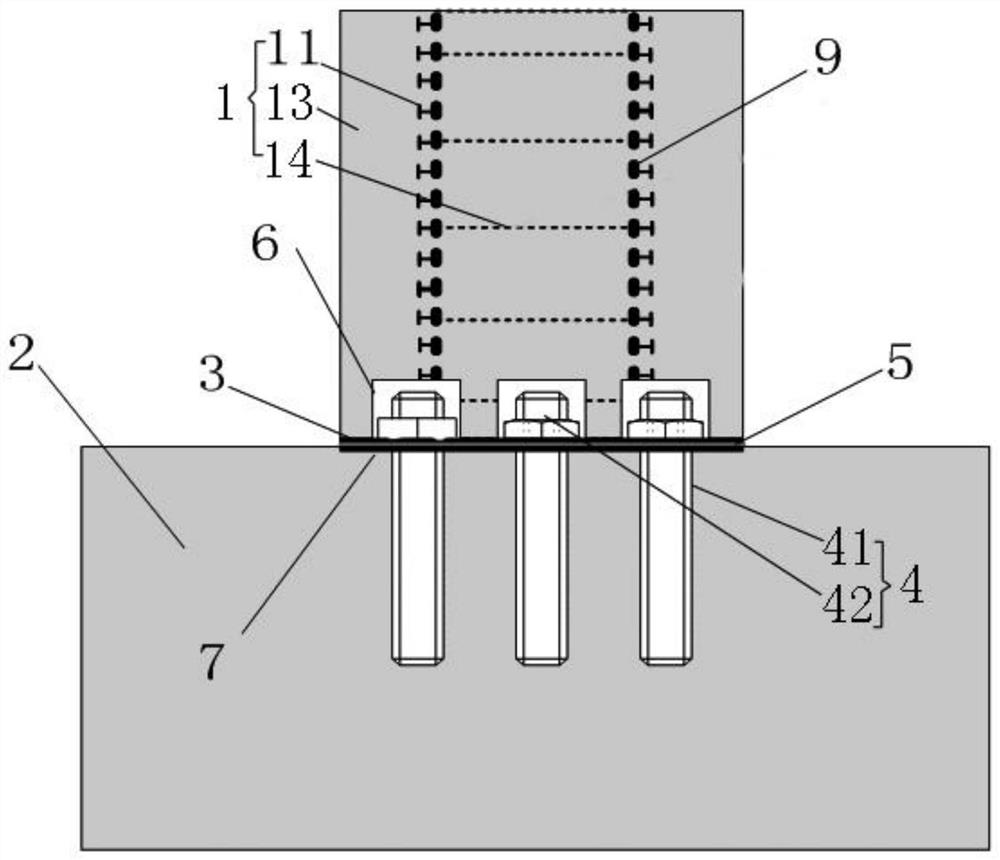

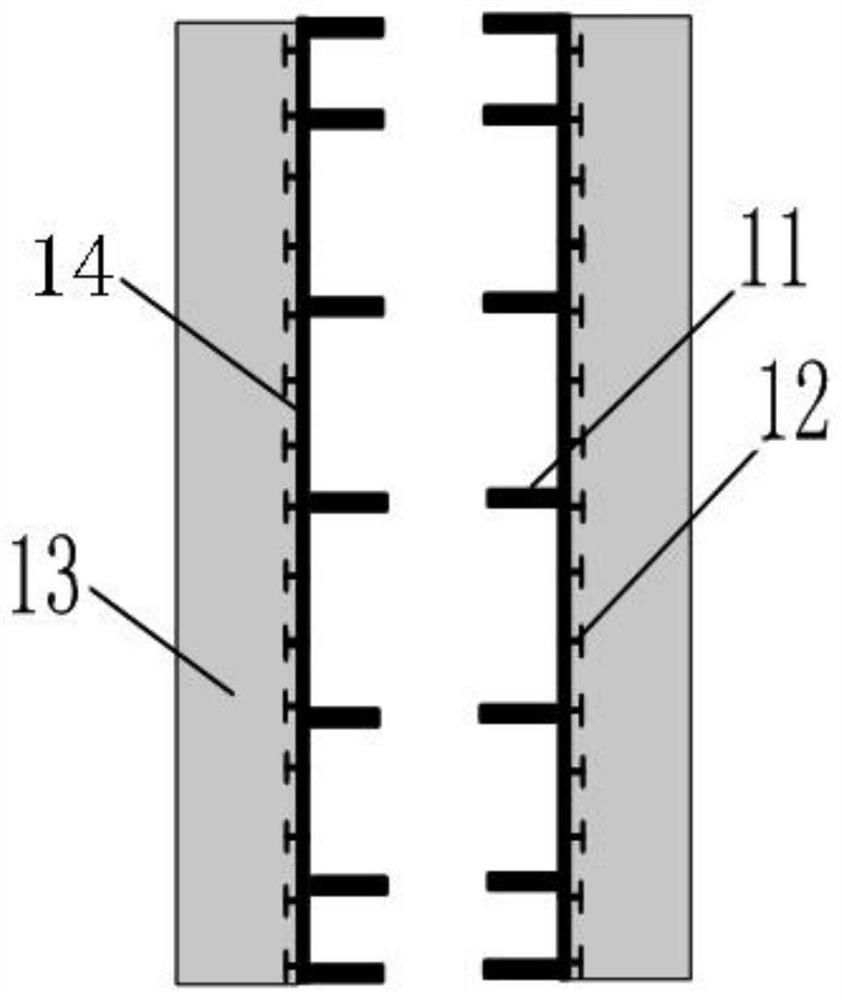

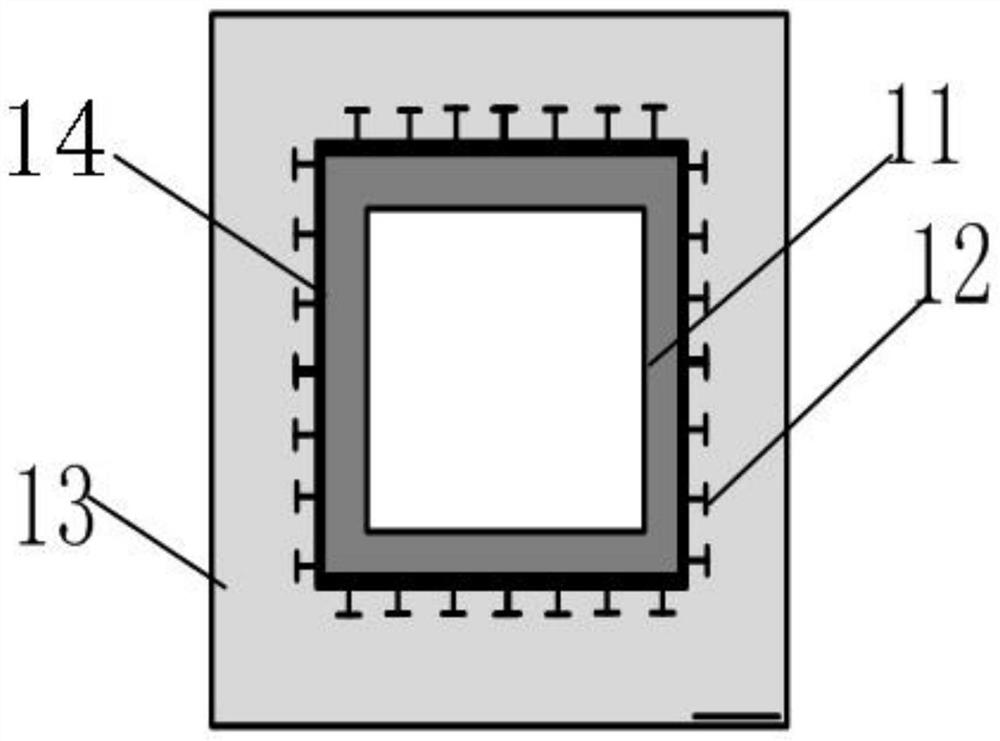

[0035]This embodiment first introduces a connection system for prefabricated composite bridge piers and caps, combiningfigure 1 , It is composed of composite bridge pier 1, bearing platform 2, steel member 3, fastener 4, epoxy resin layer 5, bolt box 6 and positioning plate 7. The composite pier 1 is composed of steel shell 14, stiffener 11, shear key 12 and reinforced concrete 13. The steel shell 14 is used as the core form of the composite pier 1, which is part of the permanent structure and participates in the common force. In order to prevent the steel shell 14 from Partial yielding occurs when the reinforced concrete 13 is poured. Stiffeners 11 are arranged around the steel shell 14. At the same time, in order to improve the reliable connection between the steel shell 14 and the reinforced concrete 13, a shear key 12 is arranged at the interface between the steel shell 14 and the reinforced concrete 13; Install the steel member 3 on the connecting end of the composite pier 1 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com