Touch type priming-coat-free BOPET matte pre-coating film and preparation method thereof

A primerless, tactile technology, applied in heat-activated films/sheets, film/sheet-like adhesives, adhesive additives, etc., can solve the problem of temperature limitations in processing procedures, severe heat shrinkage, and easy stretching and deformation, etc. problems, to achieve the effect of reducing cracking or even separation, solving the problem of high temperature resistance, and stable heat shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

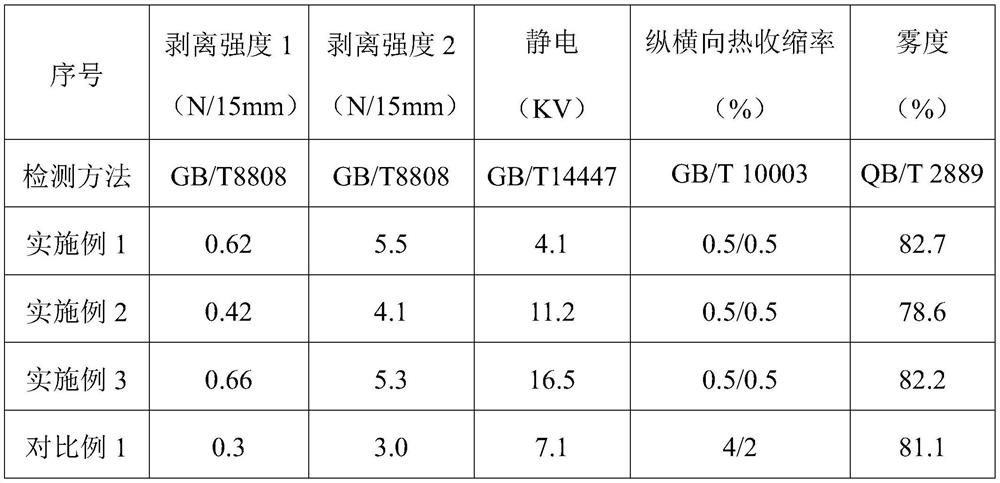

Examples

Embodiment 1

[0027] S1. Unwind the 15 μm thick biaxially oriented matte polyester film substrate without primer:

[0028] S2. Mix ethylene-vinyl acetate polymer and petroleum resin according to the weight ratio of 95:5, melt and extrude at 220°C, and compound it to the surface of the substrate without primer coating by casting method to form a hot melt adhesive layer;

[0029] S3. After cooling the film obtained in S2 on a cooling roll at 22°C, trimming and measuring the total thickness is about 30 μm, of which the thickness of the hot melt adhesive layer is about 15 μm, and then conduct high frequency on the surface of the hot melt adhesive layer High-voltage corona treatment, in which the power of high-frequency high-voltage corona treatment is 20W / m 2 , and finally wind up;

[0030] S4. Re-unwind the film wound in S3 using the reverse unwinding method, and evenly apply the water-based tactile ink to the matte surface of the substrate by gluing to form a tactile layer. After drying in a...

Embodiment 2

[0033] S1. Unwind the 15 μm thick biaxially oriented matte polyester film substrate without primer:

[0034] S2. Mix ethylene-vinyl acetate polymer and petroleum resin according to the weight ratio of 95:5, melt and extrude at 220°C, and compound it to the surface of the substrate without primer coating by casting method to form a hot melt adhesive layer;

[0035] S3. After cooling the film obtained in S2 on a cooling roll at 22°C, trimming and measuring the total thickness is about 30 μm, of which the thickness of the hot melt adhesive layer is about 15 μm, and then conduct high frequency on the surface of the hot melt adhesive layer High-voltage corona treatment, in which the power of high-frequency high-voltage corona treatment is 25W / m 2 , and finally wind up;

[0036] S4. Re-unwind the film wound in S3 using the reverse unwinding method, and evenly apply the water-based tactile ink to the matte surface of the substrate by gluing to form a tactile layer. After drying in a...

Embodiment 3

[0039] S1. Unwind the 15 μm thick biaxially oriented matte polyester film substrate without primer:

[0040] S2. Mix ethylene-vinyl acetate polymer and petroleum resin according to the weight ratio of 90:10, melt and extrude at 220°C, and compound it to the surface of the substrate without primer coating by casting method to form a hot melt adhesive layer;

[0041] S3. After cooling the film obtained in S2 on a cooling roll at 22°C, trimming and measuring the total thickness is about 30 μm, of which the thickness of the hot melt adhesive layer is about 15 μm, and then conduct high frequency on the surface of the hot melt adhesive layer High-voltage corona treatment, in which the power of high-frequency high-voltage corona treatment is 30W / m 2 , and finally wind up;

[0042] S4. Re-unwind the film wound in S3 using the reverse unwinding method, and evenly apply the water-based tactile ink to the matte surface of the substrate by gluing to form a tactile layer. After drying in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com