Method for uniformly preparing attapulgite-titanium dioxide composite material

A technology of attapulgite and titanium dioxide, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the uniformity of titanium dioxide loading cannot be controlled, the advantages and functions of nanomaterials cannot be exerted, and the surface of attapulgite cannot be controlled. The problem of uneven distribution of titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

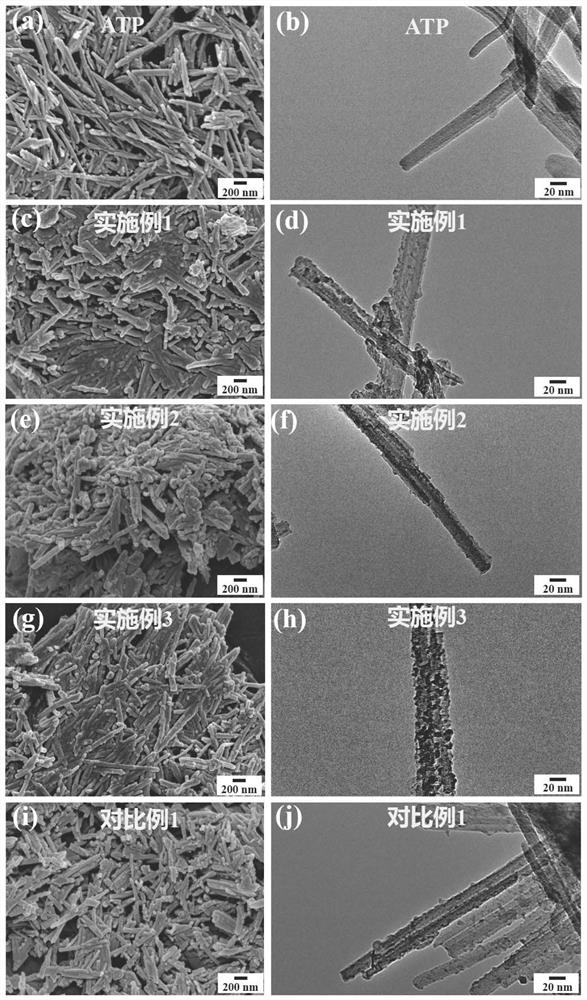

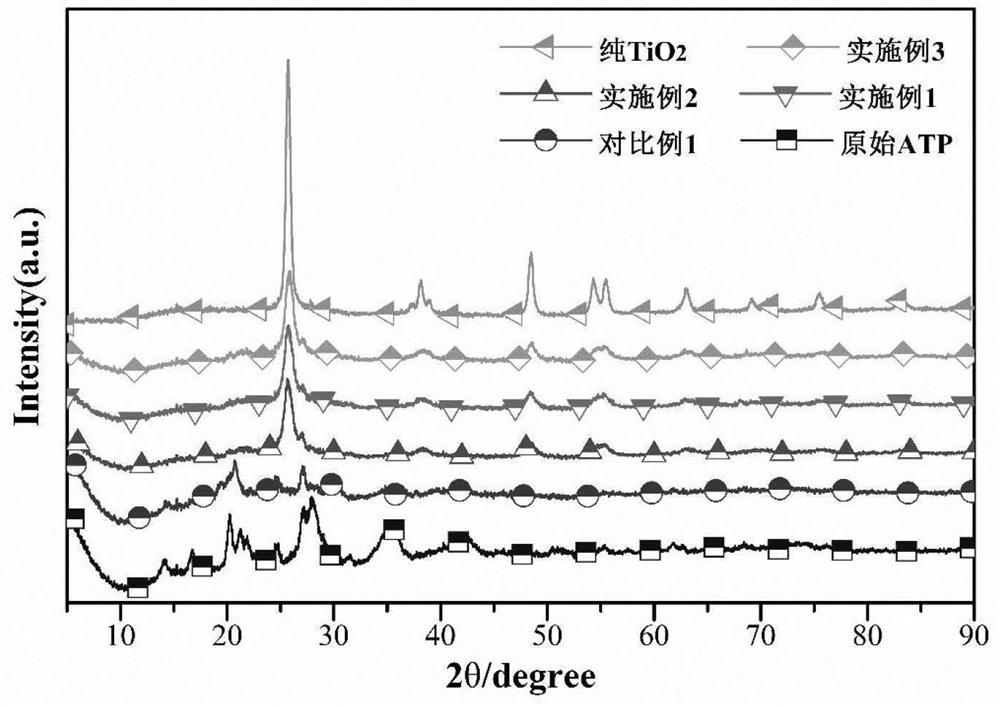

[0059] Mix 10 mL of butyl titanate with 30 mL of ethanol, then add 2 mL of acetic acid, and magnetically stir the resulting solution for 30 min (rotating at 480 rpm) to obtain a butyl titanate precursor solution;

[0060] Add 2 g of purified attapulgite to the butyl titanate precursor solution, stir magnetically for 2 h (320 rpm) and then ultrasonically disperse for 1 h. After suction filtration, add 10 mL of ethanol to the resulting product, and alternately stir (30 min, 480rpm) and ultrasonic dispersion (30min) each three times to obtain the attapulgite-butyl titanate precursor dispersion;

[0061] Put the attapulgite-butyl titanate precursor dispersion into a small beaker (100mL), place the small beaker in a large beaker (500mL), add 100mL deionized water to the periphery, and seal the large beaker with plastic wrap , placed in a water bath with magnetic stirring, rotating speed 80rpm, heating at a constant temperature of 60°C, and performing steam hydrolysis. After the rea...

Embodiment 2

[0063]Mix 10 mL of butyl titanate with 40 mL of ethanol, then add 2 mL of acetic acid, and magnetically stir the resulting solution for 20 min (320 rpm) to obtain a butyl titanate precursor solution;

[0064] Add 2 g of purified attapulgite to the butyl titanate precursor solution, stir magnetically for 2 h (320 rpm) and then ultrasonically disperse for 1 h. After suction filtration, add 10 mL of ethanol to the resulting product, and alternately stir (30 min, 320rpm) and ultrasonic dispersion (30min) each three times to obtain the attapulgite-butyl titanate precursor dispersion;

[0065] Put the attapulgite-butyl titanate precursor dispersion into a small beaker (100mL), place the small beaker in a large beaker (500mL), add 100mL deionized water to the periphery, and seal the large beaker with plastic wrap , placed in a water bath with magnetic stirring, rotating speed 160rpm, heating at a constant temperature of 40°C, and performing steam hydrolysis. After the reaction, the o...

Embodiment 3

[0067] Mix 75mL of butyl titanate with 225mL of ethanol, then add 15mL of acetic acid, and magnetically stir the resulting solution for 60min (rotating at 480rpm) to obtain a butyl titanate precursor solution;

[0068] Add 15g of purified attapulgite to the butyl titanate precursor solution, magnetically stir for 3h (rotational speed is 480rpm), then ultrasonically disperse for 3h, after suction filtration, add 50mL of ethanol to the obtained product, and alternately stir (30min, 480rpm) and ultrasonic dispersion (30min) each three times to obtain the attapulgite-butyl titanate precursor dispersion;

[0069] Put the attapulgite-butyl titanate precursor dispersion into a small beaker (100mL), place the small beaker in a large beaker (500mL), add 100mL deionized water to the periphery, and seal the large beaker with plastic wrap , placed in a water bath with magnetic stirring, rotating speed 240rpm, heating at a constant temperature of 60°C, and performing steam hydrolysis. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com