A Gradient Impedance Graphene-Based Polyimide Composite Foam Absorbing Material

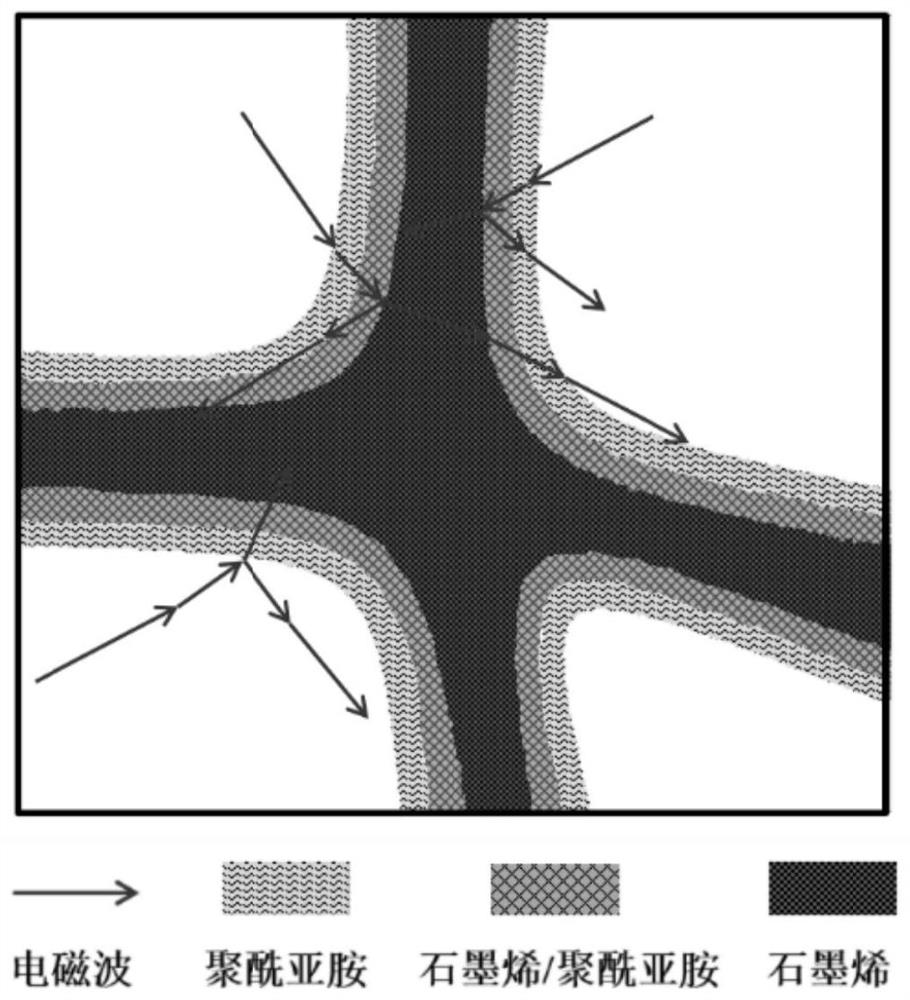

A technology of alkenyl polyimide and graphene foam, which is applied in the field of porous microwave-absorbing materials and its preparation, can solve problems such as surface impedance mismatch, narrow frequency bandwidth, and weak microwave absorption strength, and achieve improved surface impedance matching, The effect of enhancing the secondary absorption and enhancing the microwave absorption intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

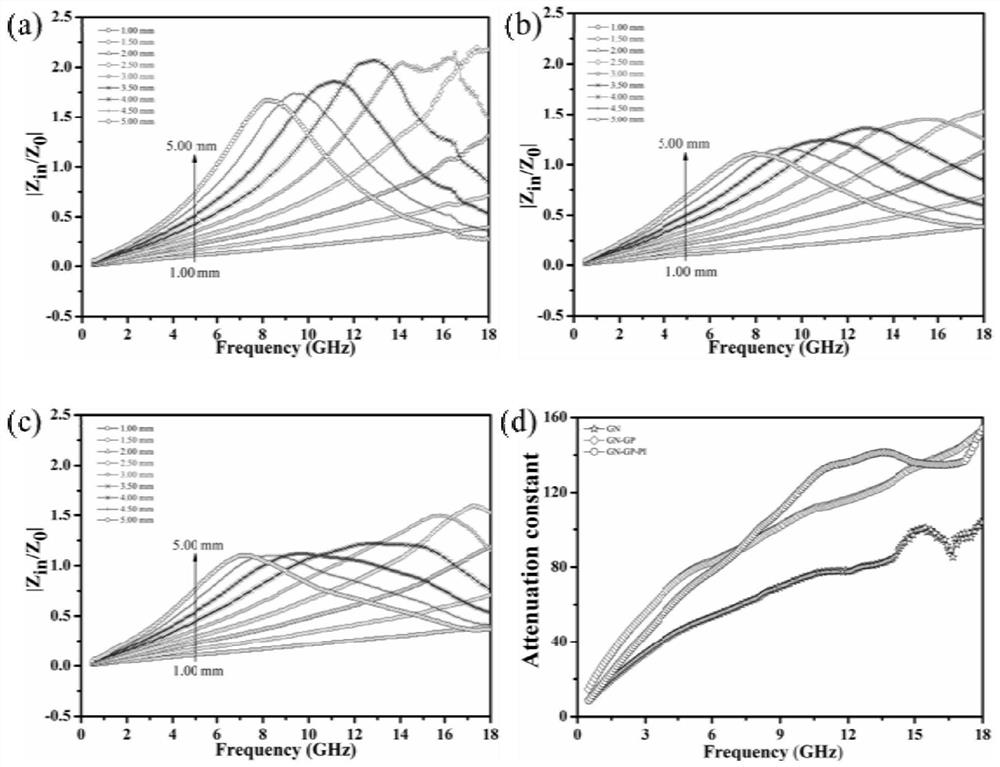

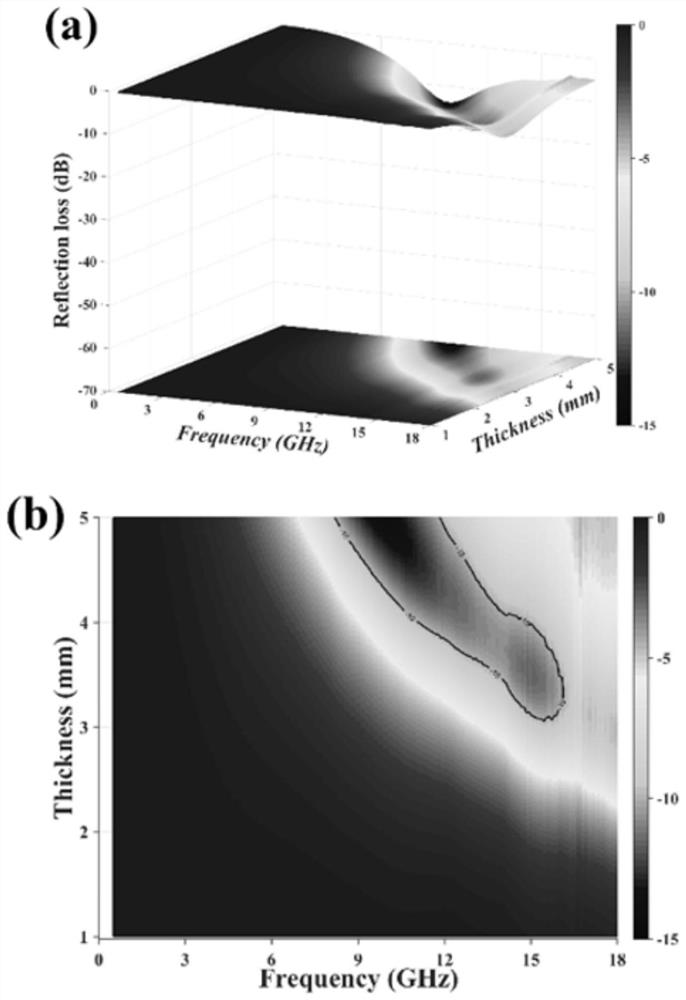

Method used

Image

Examples

Embodiment 1

[0044] (1) prepare first-grade graphene foam:

[0045] Preparation of graphene oxide: Add 2g of 325 mesh flake graphite, 240mL of concentrated sulfuric acid and 27mL of concentrated phosphoric acid into a 500mL three-necked flask, mechanically stir for 30min, then slowly add 12g of potassium permanganate, control the temperature in a water bath at 50°C, and continue stirring at a constant speed for 12h. After the reaction, the mixture was slowly poured into a beaker containing 400 mL of deionized water, and stirred evenly with a glass rod. A 30% hydrogen peroxide aqueous solution was added dropwise to the mixture, and stirred until the solution turned golden yellow, and stood overnight. Centrifuge the mixed solution to remove a large amount of acid and metal ions remaining in the mixed solution; then wash with 5% HCl solution and deionized water for several times until the pH value is close to 5-6. The obtained graphene oxide is freeze-dried for later use.

[0046] Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com