A kind of preparation method of gas chromatography sample pad

A technology for gas chromatography and sampling pads, which is applied in the field of preparation of gas chromatography sampling pads, can solve the problems of increased cost, decreased air tightness, and inability to effectively reduce the loss of sampling pads, so as to achieve reduced loss, improved mechanical properties, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

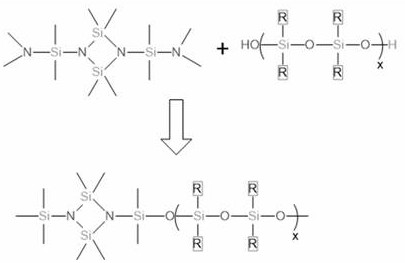

[0036] Step 1, raw material pretreatment: 100g siloxane raw rubber, 35g hydrophobic modified white carbon black, 5g iron oxide, 0.5g iron trimethylsilanol at 130 o Mixing at C for 3h, then mixing in a mixture of 0.6g 2,4-dichlorodibenzoyl peroxide and 10g hydroxyl-terminated dimethyl silicone oil to obtain pretreated raw materials;

[0037] Step 2, vulcanization molding: add the pretreated raw materials into the injection pad mold of the flat vulcanizer, and o C, pre-vulcanized molding at 9Mpa for 30 minutes to obtain a pre-vulcanized injection pad;

[0038] Step 3, post-vulcanization: put the pre-vulcanized sampling pad in a blast oven at 250 o C under treatment for 24h, to obtain a vulcanized sampling pad;

[0039]Step 4, plasma treatment: place the vulcanized sample pad in the plasma source to treat the surface, the frequency of the plasma source is 2.45GHZ, the output power is 300W, the vacuum chamber pressure is 110Pa, and the processing time is 30min to obtain the gas ...

Embodiment 2

[0046] Step 1, raw material pretreatment: 100g siloxane raw rubber, 36.8g hydrophobically modified white carbon black, 6.3g titanium dioxide, 0.7g1,1'-bis(dimethylsilyl)ferrocene at 135.4 o Mixing at C for 2.6h, then mixed with a mixture of 0.7g tert-butyl peroxybenzoate and 10.6g hydroxy-terminated methylphenyl silicone oil, to obtain pretreated raw materials;

[0047] Step 2, vulcanization molding: add the pretreated raw materials into the injection pad mold of the flat vulcanizer, at 164 o C, pre-vulcanized molding at 10.4Mpa for 26.7min to obtain a pre-vulcanized injection pad;

[0048] Step 3, post-vulcanization: put the pre-vulcanized sampling pad in a blast oven at 245 o C under treatment for 26.4h, to obtain a vulcanized sampling pad;

[0049] Step 4, plasma treatment: place the vulcanized sampling pad in the plasma source to treat the surface, the frequency of the plasma source is 2.45GHZ, the output power is 336W, the pressure of the vacuum chamber is 117.8Pa, and ...

Embodiment 3

[0056] Step 1, raw material pretreatment: 100g siloxane raw rubber, 38.9g hydrophobic modified white carbon black, 7.6g chromium trioxide, 0.9g trimethylsilanol iron at 139 o Mixing at C for 2h, then mixed with a mixture of 0.8g di-tert-butyl peroxide and 11.7g hydroxyl-terminated diphenyl silicone oil, to obtain pretreated raw materials;

[0057] Step 2, vulcanization molding: add the pretreated raw materials into the injection pad mold of the flat vulcanizing machine, at 170.4 o C, pre-vulcanized molding at 10.9 Mpa for 25.2 minutes to obtain a pre-vulcanized injection pad;

[0058] Step 3, post-vulcanization: put the pre-vulcanized sample pad into the blast oven, o C under treatment for 33.1h, to obtain a vulcanized sampling pad;

[0059] Step 4, plasma treatment: place the vulcanized injection pad in the plasma source to treat the surface, the frequency of the plasma source is 2.45GHZ, the output power is 368W, the pressure in the vacuum chamber is 121.4Pa, and the treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com