High-moisture-retention mask and preparation method thereof

A technology of high moisturizing and facial mask, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of nutrients being absorbed back by the mask and dry skin on the face, so as to improve moisturizing performance and reduce water evaporation. , good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

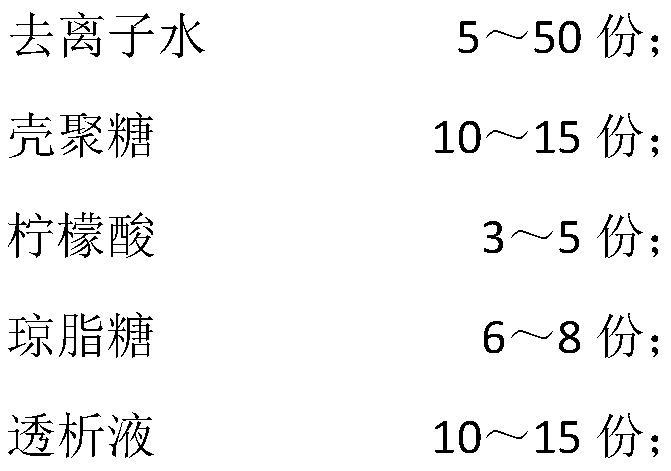

Method used

Image

Examples

preparation example Construction

[0034] According to the preparation method of the high moisturizing facial mask according to the embodiment of the second aspect of the present invention, the preparation steps include: S1, weighing the raw materials according to the formula and placing them in a blender, stirring and mixing, adjusting the pH, and homogenizing at room temperature; S2 1. Collect the homogeneous liquid and soak the base mask paper into the homogeneous liquid. After soaking under high pressure, dry and sterilize, cut and pack, and then a high moisturizing mask can be prepared.

[0035]In some specific embodiments of the present invention, the pressure of the high-pressure soaking is 0.6-0.8 MPa. By optimizing the pressure of high-pressure immersion, the moisturizing gel liquid can be more deeply and effectively combined with the base mask paper material, thereby further increasing the moisturizing time of the moisturizing mask.

[0036] In a word, the high moisturizing facial mask of the embodime...

Embodiment 1

[0040] According to the mass ratio of 3:2:2, take kelp, green algae and seaweed, mix and wash, dry naturally, freeze-dry and grind and crush, pass through a 200-mesh sieve, collect the sieved particles and press the mass ratio of 1:10. The sieved particles are stirred and mixed with deionized water and allowed to stand for 10 hours. The standing mixture is collected and filtered to obtain the filtrate and filter cake respectively. One-way refining, the distance between the grinding discs is 0.2mm, 0.1mm, 0.1mm, collect the refining fluid and place it in the deflagging machine, decompress and collect the deflagging slurry, put the deflagrating slurry in the beating machine for beating treatment and control the beating concentration to 12 %, collect the beating liquid and make paper on it, and control the weight of paper making to 45g / m 2 , after the drying is completed, collect the dried paper;

[0041] Put the filtrate collected by filtration into a dialysis bag, dialyze in a...

Embodiment 2

[0044] According to the mass ratio of 3:2:2, take kelp, green algae and seaweed, mix and wash, dry naturally, freeze-dry and grind and crush, pass through a 200-mesh sieve, collect the sieved particles and press the mass ratio of 1:10. The sieved particles were stirred and mixed with deionized water and allowed to stand for 12 hours. The standing mixture was collected and filtered to obtain the filtrate and filter cake respectively. One-way refining, the distance between the grinding discs is 0.2mm, 0.1mm, 0.1mm, collect the refining slurry and place it in the deflagging machine, decompress and collect the deflagging slurry, put the deflagrating slurry in the beating machine for beating treatment and control the beating concentration to 13 %, collect the beating liquid and make paper on it, and control the weight of paper making to 47g / m 2 , after the drying is completed, collect the dried paper;

[0045] The filtrate collected by filtration is placed in a dialysis bag, dialy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com