Insulating film for battery heat conduction and battery thereof

An insulating film and battery technology, applied in secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of battery temperature gradient difference, high battery heat generation, and temperature cannot be transmitted in time, so as to ensure consistency, Improve the service life and accelerate the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

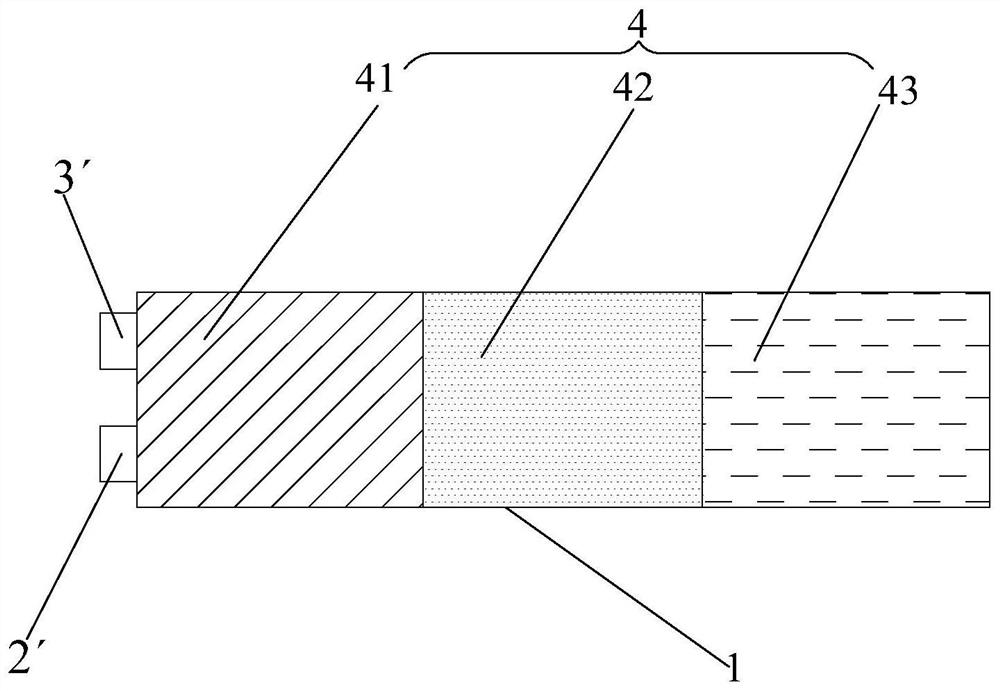

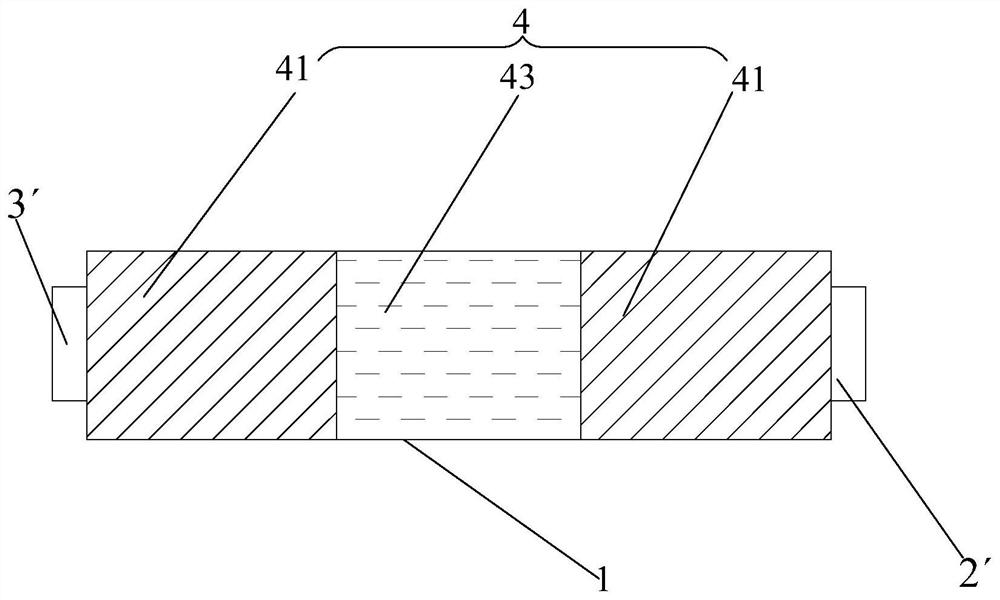

[0021] use figure 1 The structure of the prismatic battery, and the thermal conductivity of the high thermal conductivity part is 2.8W / m.K, the thermal conductivity of the middle thermal conductivity part is 2.0W / m.K, and the thermal conductivity of the low thermal conductivity part is 1.0W / m.K. The insulating film wraps the two large surfaces, the side surfaces, and the bottom surface of the battery core 1 .

[0022] The insulating film includes a PET insulating substrate and a thermally conductive glue that is formed on the PET insulating substrate by screen printing the prepared raw materials, and the insulating film is adhered to the surface of the electric core through the thermally conductive glue to wrap it. The raw materials for the preparation of thermal conductive adhesive include 35 parts of methyl vinyl polysiloxane, 8 parts of methyl hydrogen polysiloxane, 0.3 parts of platinum catalyst, 0.03 parts of 1-vinyl cyclohexanol, 20 parts of alumina, 20 parts aluminum h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com