Based on Nife 2 o 4 /sic ultraviolet photodiode and preparation method

A diode and ultraviolet light technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of low P-type silicon carbide doping concentration, and achieve the effect of improving photoelectric conversion efficiency, high withstand voltage level, and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

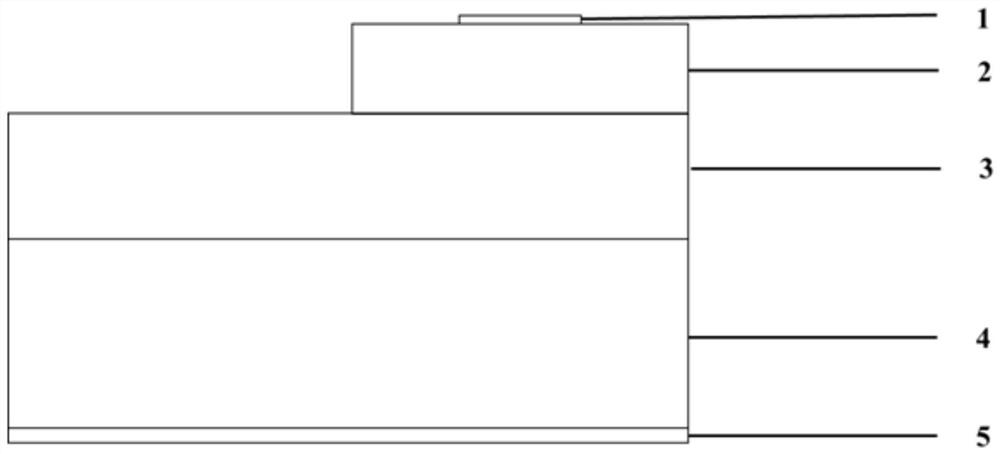

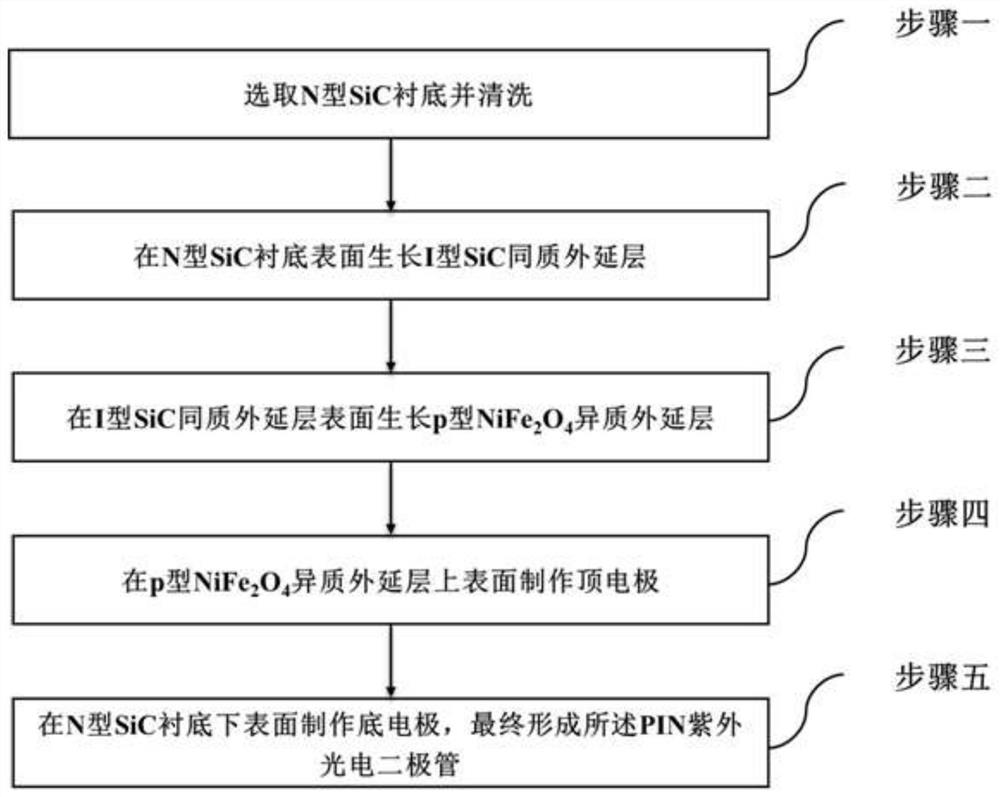

[0045] The present invention is based on a NiFe 2 o 4 / SiC ultraviolet photodiode preparation method, the flow chart is as figure 2 As shown, the specific steps are as follows:

[0046] Step 1. Clean the N-type SiC substrate, and dry it for later use;

[0047] The cleaning process in step 1 is: cleaning the N-type SiC substrate step by step with cleaning solution, 40% hydrofluoric acid solution, alcohol, and deionized water in sequence.

[0048] Step 2, growing an intrinsic 4H-SiC homoepitaxial layer on the N-type SiC substrate cleaned in the step 1;

[0049] In step 2, when the intrinsic 4H-SiC homoepitaxial layer is grown on the N-type SiC substrate, chemical vapor deposition equipment is used, silane is used as the Si source gas, propane is used as the C source gas, and hydrogen is used as the carrier gas, wherein the hydrogen The flow rate is 40-60slm, the C / Si ratio is 1:1, the growth temperature is 1520°C, and the growth time is 2min.

[0050] Step 3, performing P-...

Embodiment 2

[0057] The present invention is based on a NiFe 2 o 4 / SiC ultraviolet photodiode preparation method, the flow chart is as figure 2 As shown, the specific steps are as follows:

[0058] Step 1. Clean the N-type SiC substrate, and dry it for later use;

[0059] The cleaning process in step 1 is: cleaning the N-type SiC substrate step by step with cleaning solution, 40% hydrofluoric acid solution, alcohol, and deionized water in sequence.

[0060] Step 2, growing an intrinsic 4H-SiC homoepitaxial layer on the N-type SiC substrate cleaned in the step 1;

[0061] In step 2, when the intrinsic 4H-SiC homoepitaxial layer is grown on the N-type SiC substrate, chemical vapor deposition equipment is used, silane is used as the Si source gas, propane is used as the C source gas, and hydrogen is used as the carrier gas, wherein the hydrogen The flow rate is 40-60slm, the C / Si ratio is 3:2, the growth temperature is 1600°C, and the growth time is 5min.

[0062] Step 3, performing P-...

Embodiment 3

[0069] The present invention is based on a NiFe 2 o 4 / SiC ultraviolet photodiode preparation method, the flow chart is as figure 2 As shown, the specific steps are as follows:

[0070] Step 1. Clean the N-type SiC substrate, and dry it for later use;

[0071] The cleaning process in step 1 is: cleaning the N-type SiC substrate step by step with cleaning solution, 40% hydrofluoric acid solution, alcohol, and deionized water in sequence.

[0072] Step 2, growing an intrinsic 4H-SiC homoepitaxial layer on the N-type SiC substrate cleaned in the step 1;

[0073] In step 2, when the intrinsic 4H-SiC homoepitaxial layer is grown on the N-type SiC substrate, chemical vapor deposition equipment is used, silane is used as the Si source gas, propane is used as the C source gas, and hydrogen is used as the carrier gas, wherein the hydrogen The flow rate is 50slm, the C / Si ratio is 2.5:2, the growth temperature is 1580°C, and the growth time is 4min.

[0074] Step 3, performing P-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com