Preparation method of silk fibroin nanofiber whiskers

A technology of silk fibroin and nanofibers, applied in the preparation of silk fibroin nanofiber whiskers, using ultrasonic-assisted sulfuric acid to prepare silk fibroin nanofiber whiskers, can solve the complex preparation process and long time-consuming silk fibroin nanofibers , fewer preparation methods, etc., to achieve good repeatability, good product recovery, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

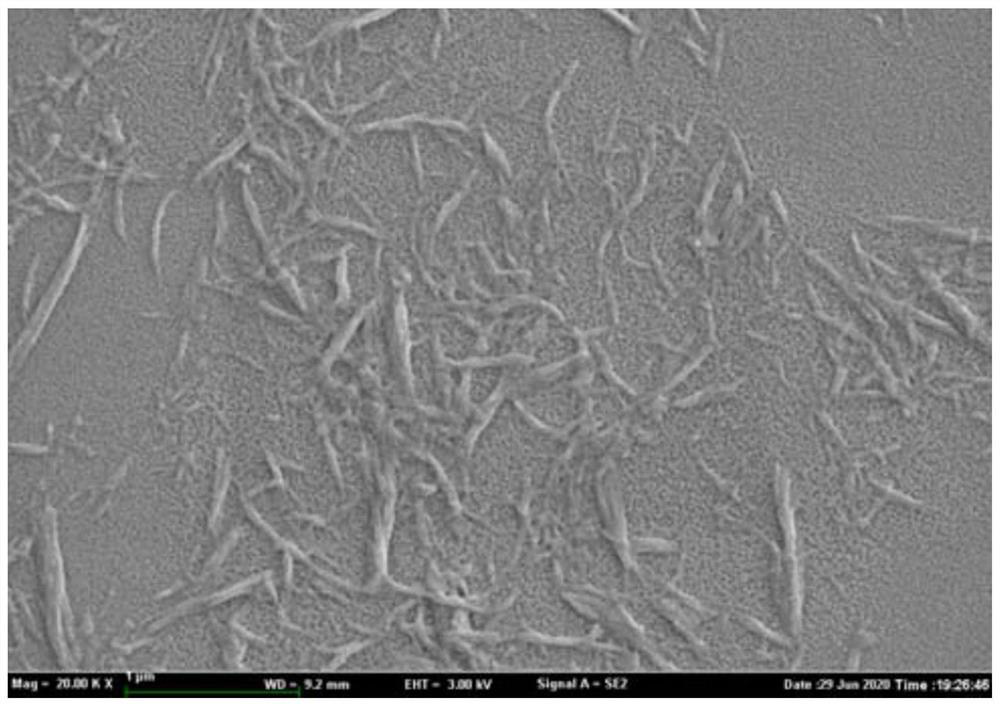

Image

Examples

Embodiment 1

[0023] 1) Cut silkworm cocoons into about 1×1cm 2 For small pieces, use 1000ml of 0.5% (w / w) Na 2 CO 3 The solution was boiled for 30 minutes to degumming, washed with deionized water repeatedly, repeated 3 times, and dried overnight at 60°C to obtain silk fibroin;

[0024] 2) Configure 60wt% H 2 SO 4 After solution, preheat it to 45°C in a constant temperature water bath, transfer it to a 100w ultrasonic reactor, pull apart the more obvious entangled parts of the silk fibroin obtained in step 1), and put it in a preheated well H 2 SO 4 React in the solution for 30min, silk fibroin and H 2 SO 4 The mass ratio of the solution is 1:10, the reaction is terminated by using room temperature deionized water with 5 times the volume of the acid solution, and the acid solution is cleaned to obtain the reactant;

[0025] 3) The reactant obtained in step 2) is diluted with deionized water, neutralized with 0.2wt% NaOH solution, and cleaned with deionized water to desalinize the s...

Embodiment 2

[0029] 1) Cut silkworm cocoons into about 1×1cm 2 For small pieces, use 1000ml of 0.5% (w / w) Na 2 CO 3 The solution was boiled for 30 minutes to degumming, washed with deionized water repeatedly, repeated 3 times, and dried overnight at 60°C to obtain silk fibroin;

[0030] 2) Configure 45wt% H 2 SO 4 After solution, preheat it to 75°C in a constant temperature water bath, transfer it to a 100w ultrasonic reactor, pull apart the more obvious entangled parts of the silk fibroin obtained in step 1), and put it in a preheated well H 2 SO 4 React in the solution for 30min, silk fibroin and H 2 SO 4 The mass ratio of the solution is 1:10, the reaction is terminated by using room temperature deionized water with 5 times the volume of the acid solution, and the acid solution is cleaned to obtain the reactant;

[0031] 3) The reactant obtained in step 2) is diluted with deionized water, neutralized with 0.05wt% NaOH solution, and cleaned with deionized water to desalinize the ...

Embodiment 3

[0035]1) Cut silkworm cocoons into about 1×1cm 2 For small pieces, use 1000ml of 0.5% (w / w) Na 2 CO 3 The solution was boiled for 30 minutes to degumming, washed with deionized water repeatedly, repeated 3 times, and dried overnight at 60°C to obtain silk fibroin;

[0036] 2) Take a dialysis bag with an appropriate length and a molecular weight cut-off of 7000kDa, boil it with deionized water for 10 minutes, wash it with deionized water for 3 times, and set aside;

[0037] 3) Configure 45wt% H 2 SO 4 After solution, put it in a constant temperature water bath and preheat it to 45°C, transfer it to a 200w ultrasonic reactor, pull apart the more obvious entangled part of the silk fibroin obtained in step 1), and put it in a preheated well H 2 SO 4 React in solution for 180min, silk fibroin and H 2 SO 4 The mass ratio of the solution is 1:20, the reaction is terminated by using room temperature deionized water with 5 times the volume of the acid solution, and the acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com