A macro-preparation method of polyvinylpyrrolidone-modified nano-silver wire powder

A technology of polyvinylpyrrolidone and nano-silver wire, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of poor powder dispersibility, complex production process, complex process, etc., and achieve good dispersion and good repeatability , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) At room temperature, in the dark, 1.36g of silver nitrate was dissolved in 80mL of ethylene glycol to obtain an ethylene glycol solution of silver nitrate; at room temperature, 2.16mg of ferric chloride hexahydrate and 1.34g of polyethylene Pyrrolidone (PVP) is successively dissolved in 80mL of ethylene glycol to obtain an ethylene glycol solution containing polyvinylpyrrolidone, and the two solutions are simultaneously added to the container under stirring.

[0028] (2) Put the above mixed solution in a 200mL hydrothermal reaction kettle, and heat it in an oven at 160°C for 12 hours;

[0029] (3) After naturally cooling to room temperature, the precipitate is taken out, vacuum filtered to dryness, and ethylene glycol and PVP on the surface of the precipitate are washed away with acetone and ethanol;

[0030] (4) Dry the filter cake in step (3) in a blast drying oven at 60° C. for 2 hours to obtain a PVP-modified silver nano wire powder.

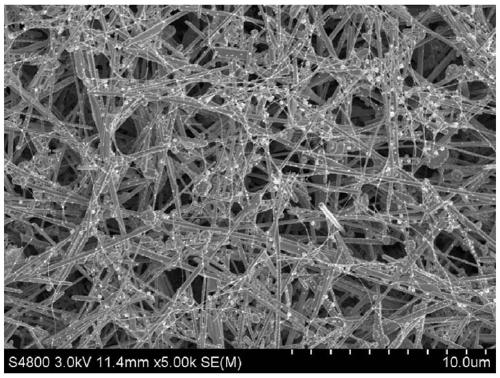

[0031] The powder prepare...

Embodiment 2

[0034] (1) Dissolve 0.68g of silver nitrate in 40mL of ethylene glycol under dark conditions to obtain an ethylene glycol solution of silver nitrate; dissolve 1.08mg of ferric chloride hexahydrate and 0.89g of polyvinylpyrrolidone in ethylene glycol In 40mL of alcohol, the ethylene glycol solution containing polyvinylpyrrolidone was obtained, and the two solutions were simultaneously added to the container under stirring.

[0035] (2) Put the above mixed solution in a 100mL hydrothermal reaction kettle, and heat it in an oven at 160°C for 12 hours;

[0036] (3) After naturally cooling to room temperature, the precipitate is taken out, vacuum filtered to dryness, and ethylene glycol and PVP on the surface of the precipitate are washed off with acetone and ethanol in turn;

[0037] (4) The filter cake in step (3) was vacuum-dried in a vacuum oven at 60° C. for 2 hours to obtain a PVP-modified silver nano wire powder.

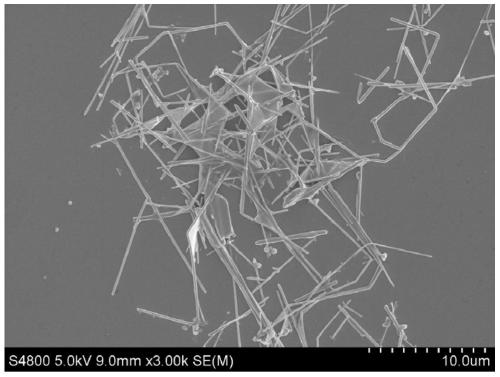

[0038] Such as figure 2 As shown, the diameter of the nan...

Embodiment 3

[0040] (1) In the dark, dissolve 0.68g of silver nitrate in 40mL of ethylene glycol to obtain an ethylene glycol solution of silver nitrate; successively dissolve 0.7mg of sodium chloride and 0.89g of polyvinylpyrrolidone in 40mL of ethylene glycol , to obtain an ethylene glycol solution containing polyvinylpyrrolidone, and to simultaneously add the two solutions into the container while stirring.

[0041] (2) Put the above mixed solution in a 100mL hydrothermal reaction kettle, and heat it in an oven at 160°C for 8 hours;

[0042] (3) After naturally cooling to room temperature, the precipitate is taken out, vacuum filtered to dryness, and ethylene glycol and PVP on the surface of the precipitate are washed off with acetone and ethanol in turn;

[0043] (4) The filter cake in step (3) was vacuum-dried in a vacuum drying oven at 60° C. for 2 hours to obtain a PVP-modified silver nano wire powder.

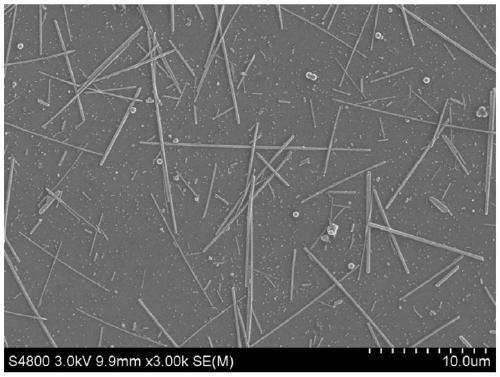

[0044] The nano-silver wire prepared by the invention can be dispersed in wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com