Irradiation-resistant melt-blown polypropylene composite material as well as preparation method and application thereof

A composite material, polypropylene technology, applied in the direction of single-component polyolefin rayon, rayon manufacturing, textiles and papermaking, etc., can solve problems such as the influence of polypropylene meltblown properties, and achieve the effect of suitable fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

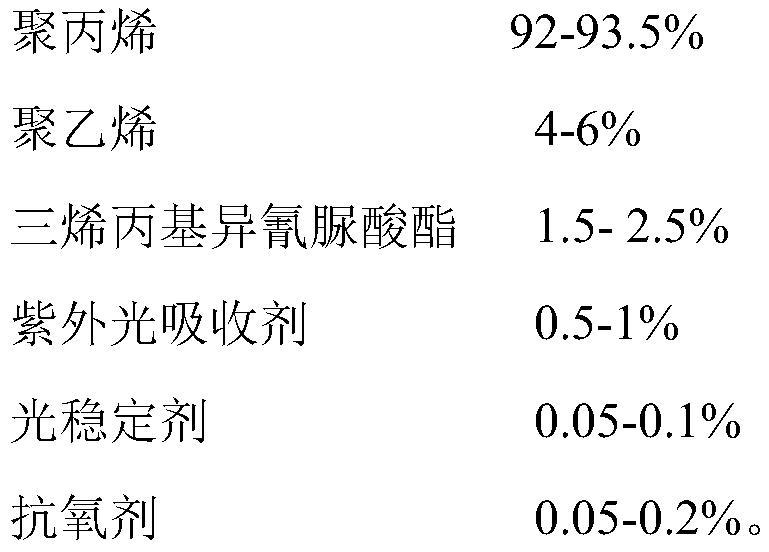

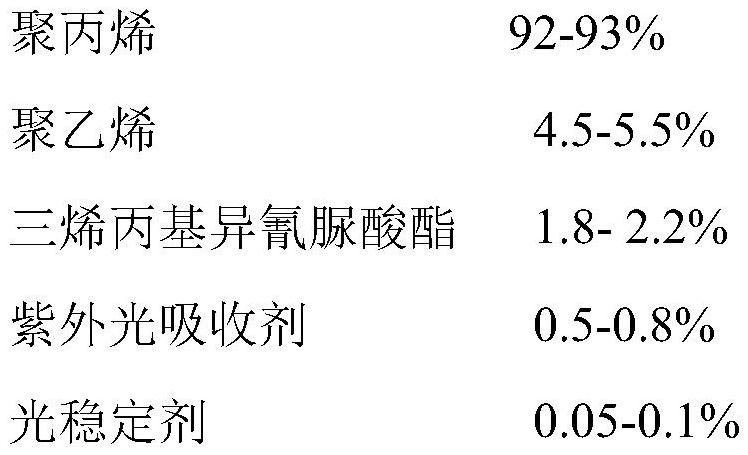

[0031] These examples provide a radiation-resistant melt-blown polypropylene composite material, and the dosage of specific components is shown in Table 1.

[0032] Table 1

[0033]

[0034] Among them, in Table 1, polypropylene is CGN Juner’s special polypropylene for melt-blown cloth, the model is PPB-1500; polyethylene is Dow Chemical Company’s 2045G polyethylene; the ultraviolet light absorber is triazole ultraviolet light absorber UV-328 was purchased from Shanghai Macklin Technology Co., Ltd.; the light stabilizer was polymeric high molecular weight hindered amine light stabilizer 622, purchased from Shanghai Macklin Technology Co., Ltd.; the antioxidant was 4,4′-methylene Bis(2,6-di-tert-butylphenol) (antioxidant 702) was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0035] The preparation method of the above-mentioned radiation-resistant melt-blown polypropylene composite material includes the following steps: weighing each raw material accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com