A joint ball seat turning-milling compound processing and inner spherical surface grinding method

A technology of composite processing and grinding method, applied in the field of aero-engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

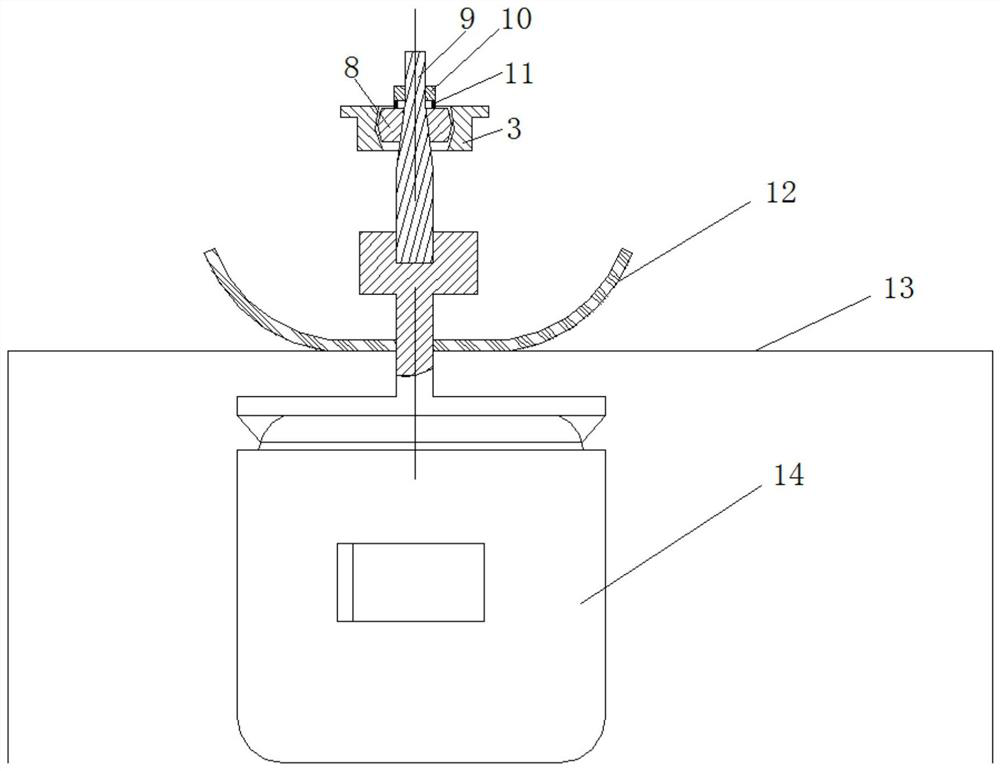

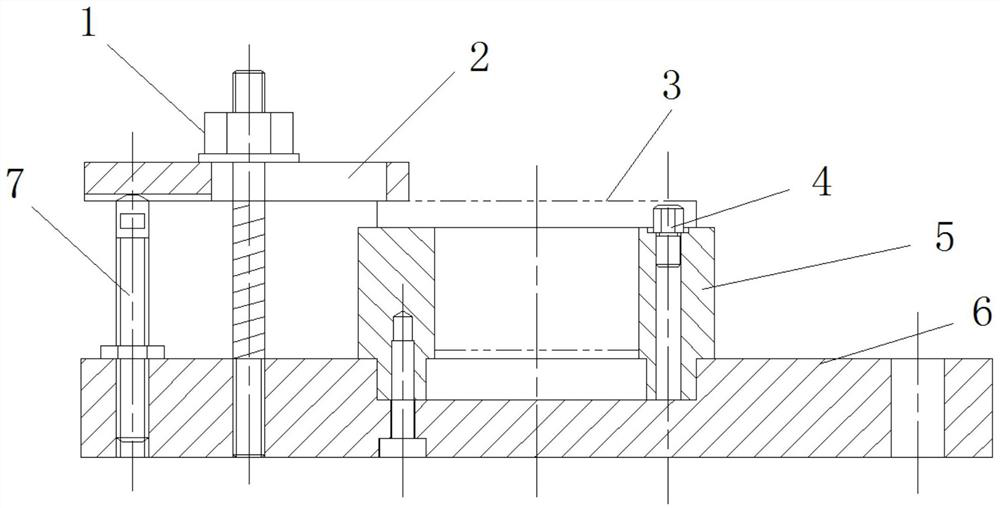

[0036] The material of the joint ball seat part is alloy structural steel, the outermost diameter is φ120mm, the size of the inner spherical surface 17 is: Sφ55mm, the tolerance of the spherical surface is 0.015~0.046mm, the roughness of the inner spherical surface 17 is Ra0.4um, the thickness of the part is 30mm, and the groove The width of 16 is 28mm, the tolerance is 0.1mm, the length of groove 16 is 55mm, and the radius of transfer fillet of groove 16 is R2.5mm.

[0037] like Figure 1 to Figure 9 As shown, a joint ball seat turning-milling compound processing and inner spherical surface grinding method includes the following steps:

[0038] Step 1, parts clamping: install the outer cylinder of the joint ball seat part 3 into the inner hole of the fixture positioning ring 5, the installation hole 15 of the joint ball seat part 3 is matched with the fixture positioning pin 4, adjust the position of the pressure plate 2, and use the compression screw Cap 1 is compressed;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com