Air duct opening sealing viscose sponge with novel structure and preparation process thereof

A viscose sponge and air duct technology, which is used in adhesives, household refrigeration devices, lighting and heating equipment, etc., can solve problems such as no cooling, air leakage from air ducts, and freezing, and achieve the effect of realizing product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

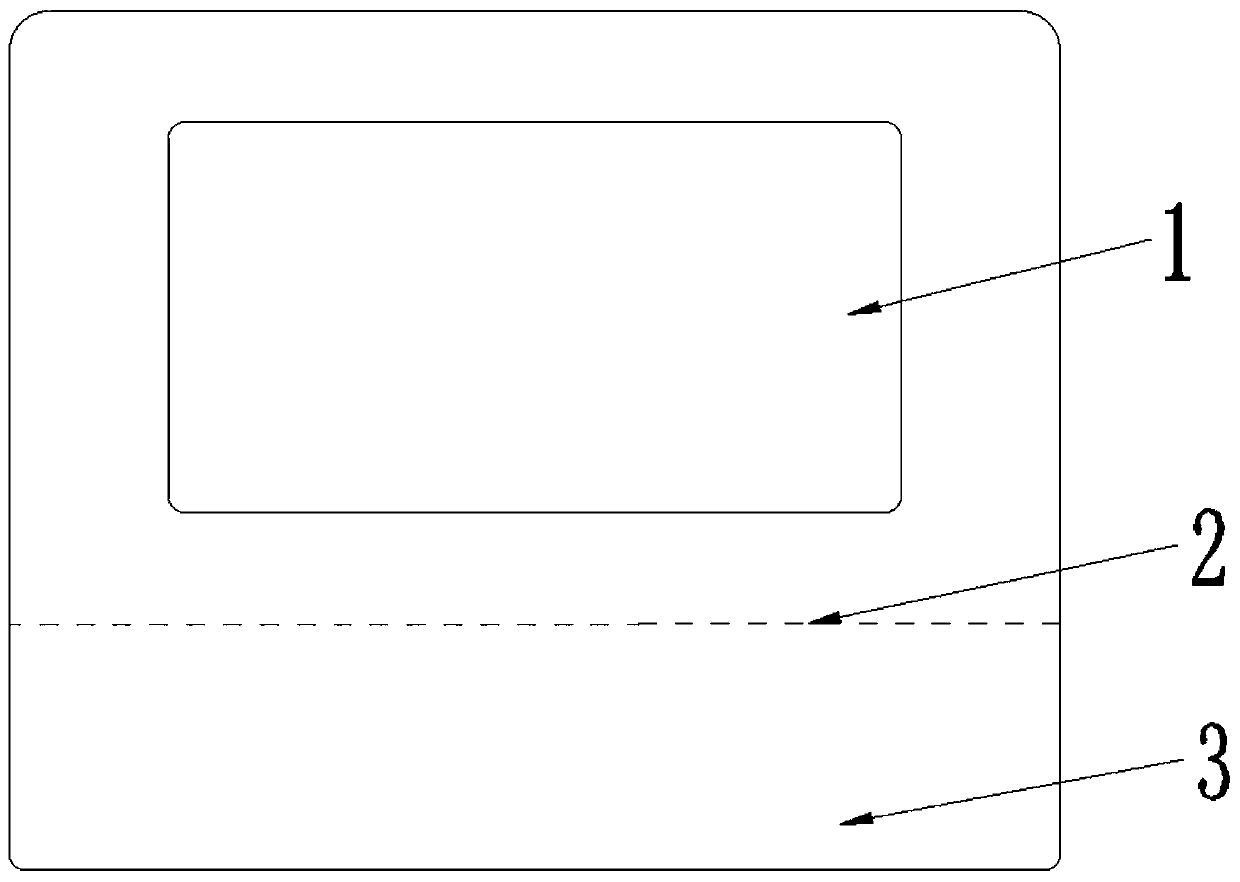

Image

Examples

Embodiment 2

[0038] The sponge synthetic material in the viscose sponge includes the following parts by weight: 90 parts of EPDM rubber, 1 part of vulcanizing agent, 60 parts of filler, 6 parts of modified foaming agent, 0.5 part of processing aid, 6 parts of active agent zinc oxide, stearin 0.5 parts of acid, 1 part of antioxidant, 1 part of paraffin and 2 parts of dispersant.

Embodiment 3

[0040] The sponge synthetic material in the viscose sponge includes the following parts by weight: 95 parts of EPDM rubber, 1.5 parts of vulcanizing agent, 65 parts of filler, 6.5 parts of modified foaming agent, 0.7 part of processing aid, 6.3 parts of active agent zinc oxide, stearin 0.7 parts of acid, 1.1 parts of antioxidant, 1.2 parts of paraffin and 2.2 parts of dispersant.

Embodiment 4

[0042] The synthetic material of the sponge in the viscose sponge includes the following parts by weight: 97 parts of EPDM rubber, 1.7 parts of vulcanizing agent, 70 parts of filler, 7 parts of modified foaming agent, 1.1 parts of processing aid, 7 parts of active agent zinc oxide, stearin 1.2 parts of acid, 1.2 parts of antioxidant, 1.5 parts of paraffin and 2.5 parts of dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap