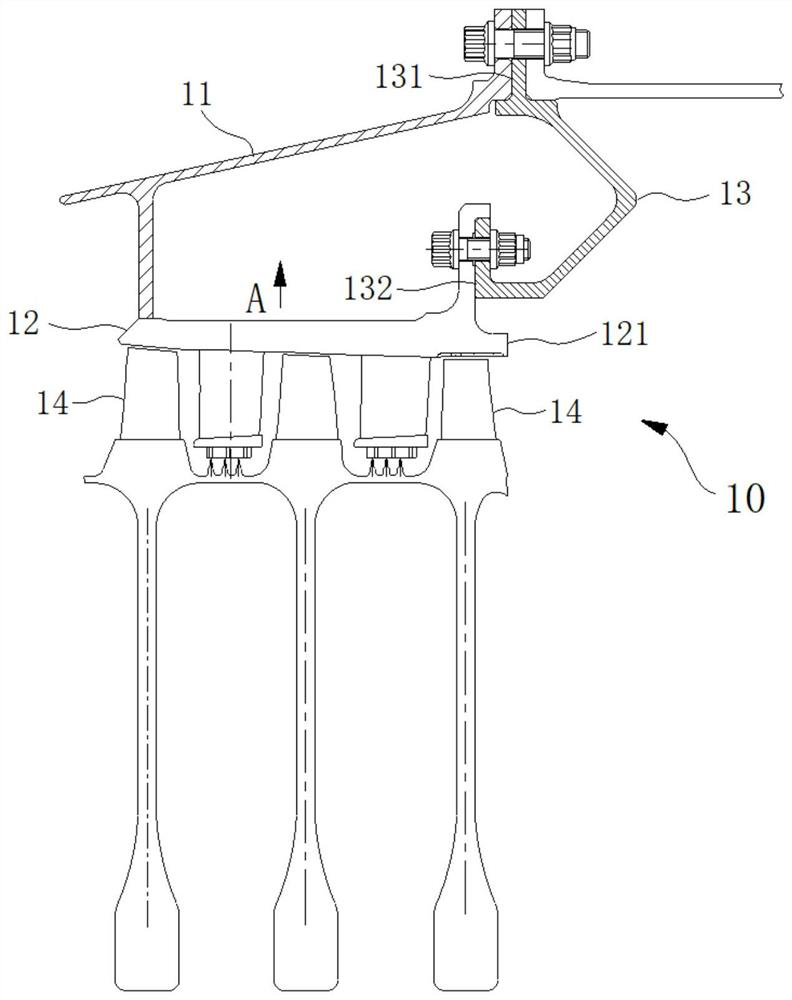

A bearing ring assembly and its double-layer case structure

A load-bearing ring and component technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as failure to assemble, engine failure to operate normally, and achieve the effect of avoiding titanium fire problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

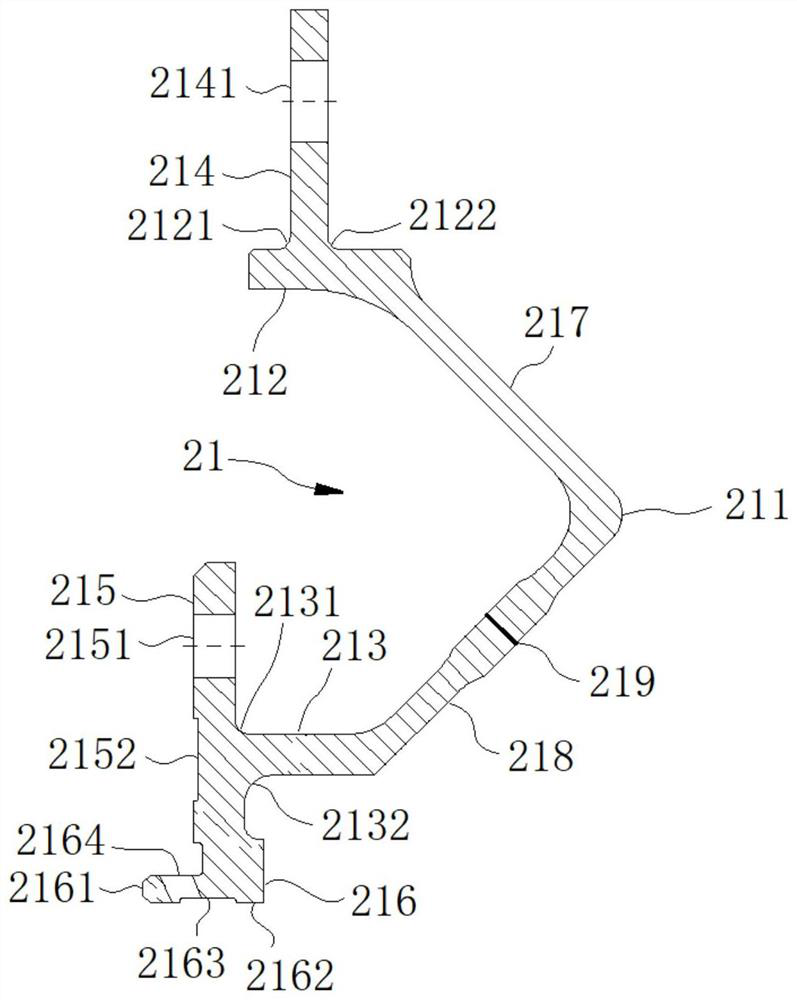

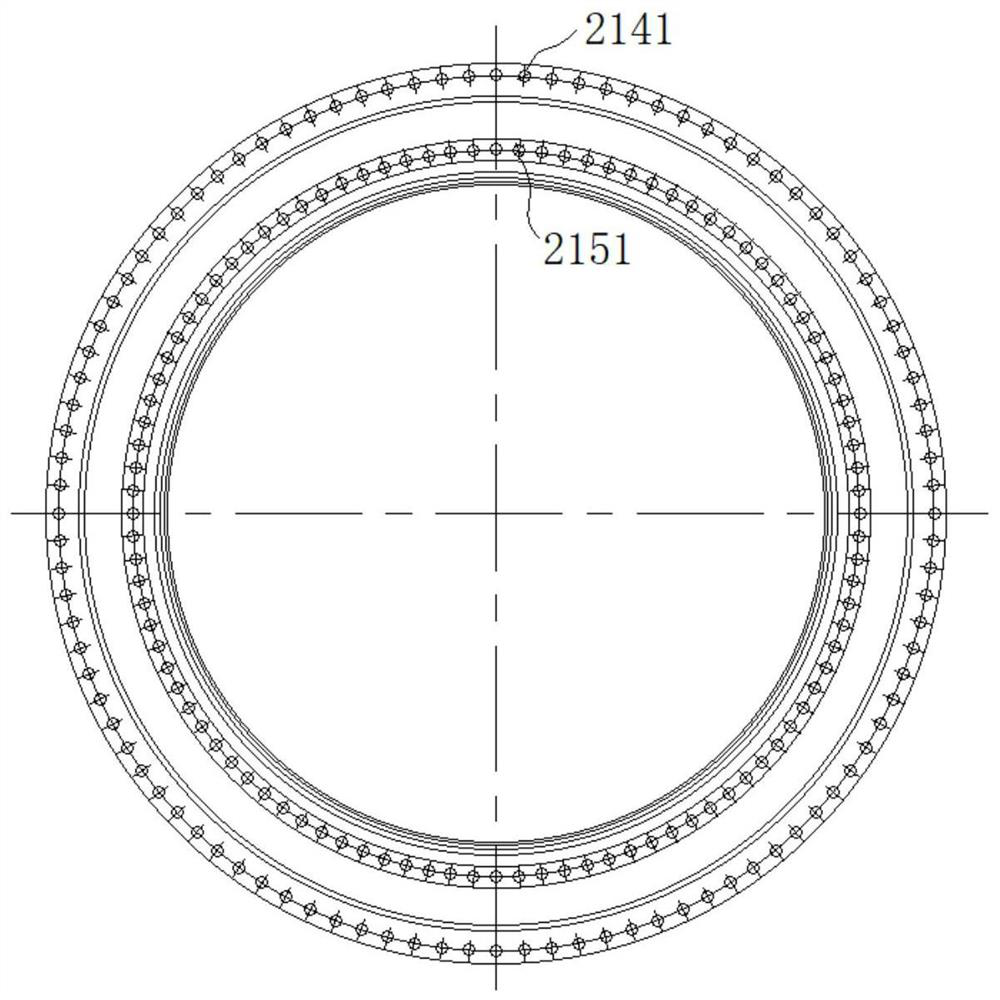

[0049] Such as figure 2 As shown, the bearing ring assembly provided in the present application includes a bearing ring 21 , a rotor outer ring 22 and pins 23 . The bearing ring 21 has a body 211 in the shape of a broken line, and the angle of the broken line is 80° to 100°, and the embodiment in the drawings of this application is about 90°. A first transverse portion 212 and a second transverse portion 213 extending substantially parallel to each other extend from both ends of the body 211, and a first radial portion 214 radially extends from approximately the middle of the first transverse portion 212. The first transverse portion 212 and the first radial portion 214 can form a first notch 2121 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com