Fretting fatigue performance prediction method based on artificial neural network

An artificial neural network and fretting fatigue technology, applied in the field of artificial intelligence, can solve problems such as failure to achieve global optimality and high cost, reduce the cost of fretting fatigue experiments and numerical calculations, improve prediction accuracy, and reduce experimental and numerical calculations. Calculating cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

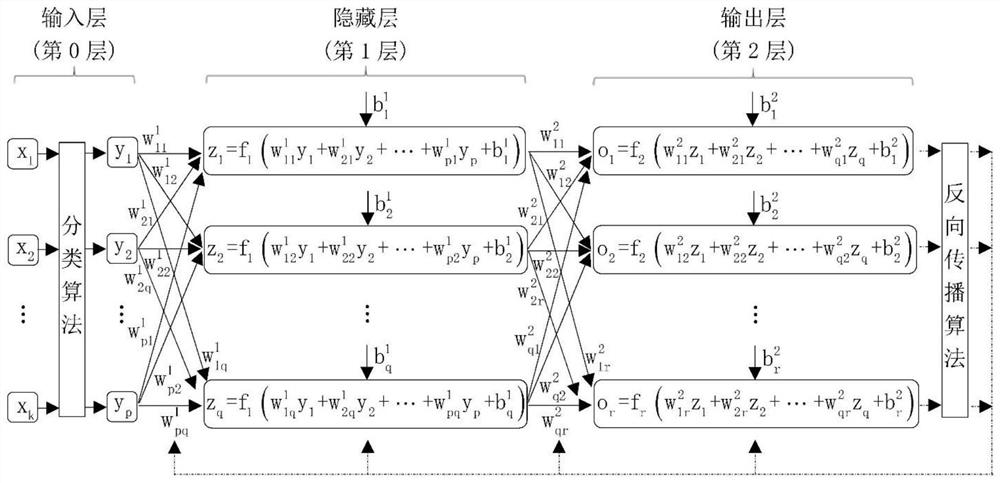

[0028] Example: see figure 1 .

[0029] A fretting fatigue performance prediction method based on artificial neural network, the elastic modulus, Poisson's ratio and stress-strain curve of the material are obtained through the uniaxial tensile test, and the fatigue strength coefficient and fatigue strength index of the material are obtained through the axial equal-amplitude fatigue test , using the fracture mechanics experiment to obtain the material constant of the fatigue crack growth stage, and based on the fretting fatigue experiment, the crack initiation position, crack initiation angle, crack initiation life, crack propagation path, and crack growth life of the fretting fatigue specimen were obtained;

[0030] Construct the numerical model of fretting fatigue, use the data of uniaxial tensile test, axial constant amplitude fatigue test and fracture mechanics experiment, combine the finite element method and extended finite element method, establish the numerical model of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com