Planetary roller screw rod adopting gear transmission mode

A technology of planetary roller and gear transmission, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc. It can solve problems such as uncertain lead and large noise, and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

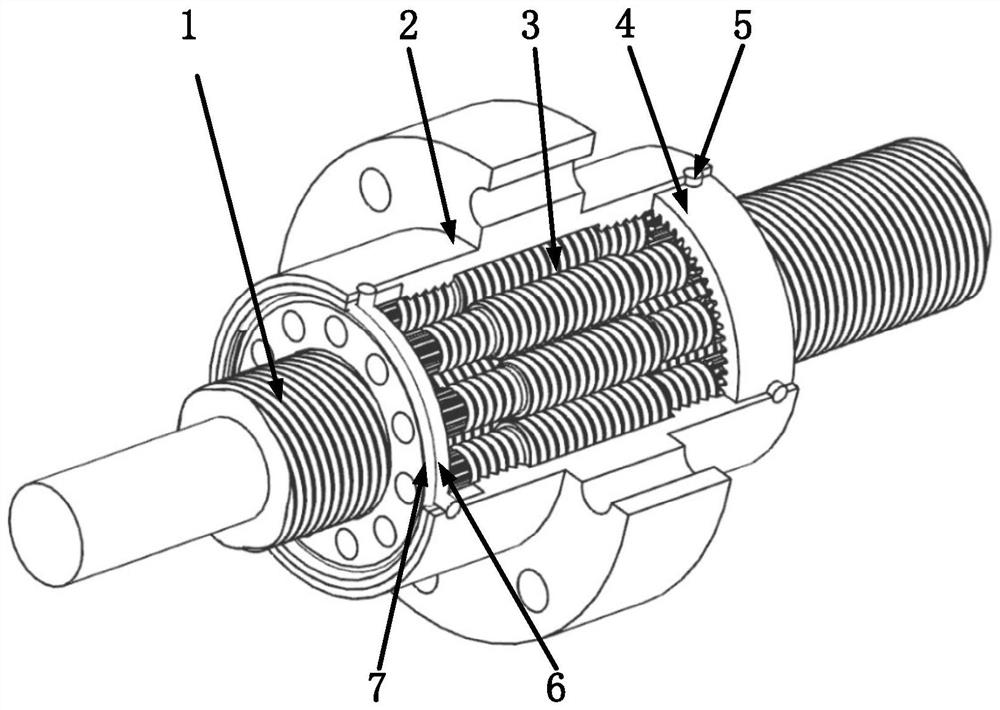

[0026] Such as figure 1 As shown, a planetary roller screw with a gear transmission method includes a screw 1, a nut 2, a roller 3, an inner ring gear 4, a fixed pin 5, a planet carrier 6, a retaining ring 7 and other parts.

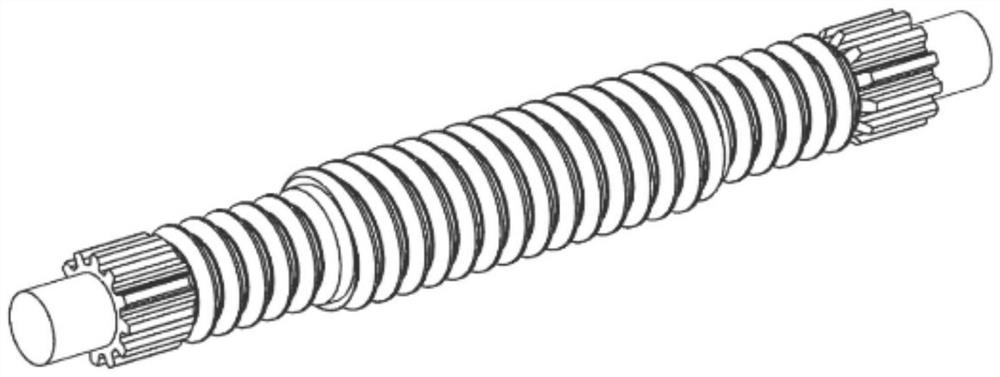

[0027] Such as figure 2 , Shown in 3, the middle of the roller 3 outwards is the screw thread 3-1, the ring tooth 3-2, the gear 3-3 and the optical axis 3-4. The middle of the roller 3 is a thread structure, which is generally a single-start thread, and the pitch of the thread is the same as that of the lead screw 1; the outside of the thread is a ring tooth structure, and the outer diameter of the ring tooth 3-2 is generally smaller than the bottom of the thread 3-1 Diameter, to avoid interference with the screw thread, mainly used to bear the axial force and some possible radial force, in order to prevent the ring teeth 3-2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com