Compact planetary roller screw in circular ring friction transmission mode

A technology of friction transmission and planetary rollers, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as high noise and uncertain lead, reduce manufacturing processes, improve efficiency, and reduce meshing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

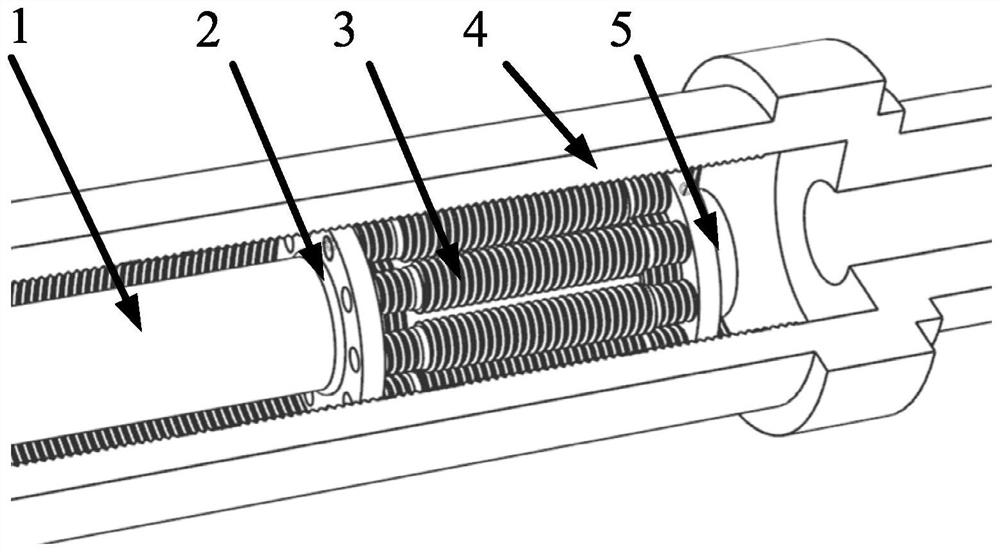

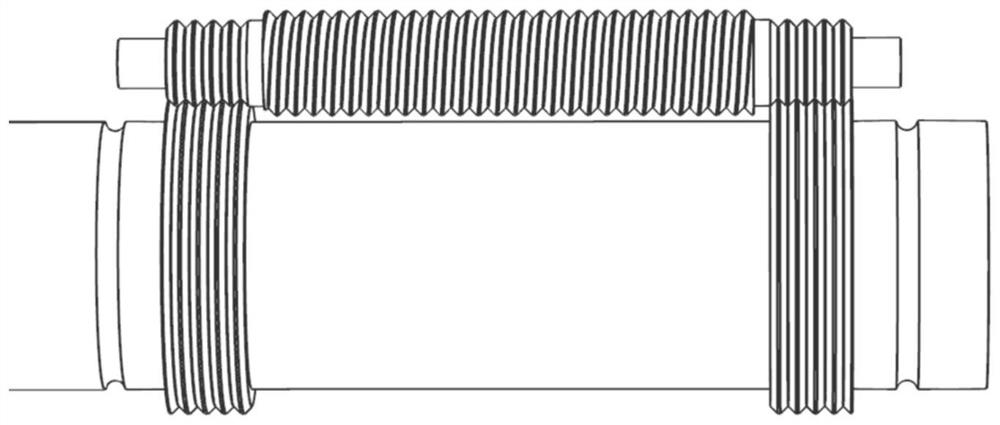

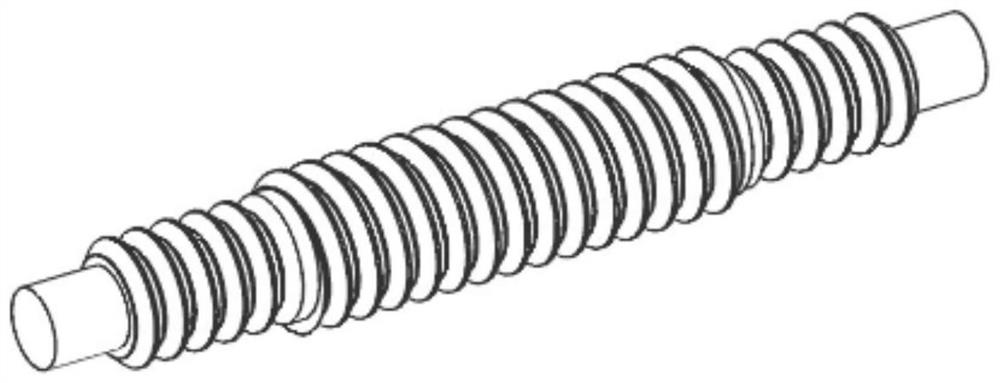

[0027] Such as figure 1 , Shown in 2, the planetary roller screw of the ring friction transmission mode of the present invention includes parts such as a screw 1, a retaining ring 2, a roller 3, a nut 4, and a planet carrier 5. The rollers 3 are evenly distributed around the lead screw 1, the thread in the middle meshes with the thread of the nut 4 but not the lead screw, the rings at both ends of the roller 3 mesh with the rings at both ends of the lead screw 1, and the two The shaft head at the end cooperates with the evenly distributed circular holes on the planet carrier 5 to avoid collision and friction between the rollers and improve the stress state. The left and right planetary carriers are installed on the optical axis installation position outside the screw gear structure, and the steel wire retaining ring is installed in the groove of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com