Goaf coal gangue supporting solid filling method

A supportive, goaf technology, used in fillings, mining equipment, earthwork drilling, etc., can solve the problems of material compaction coefficient and compaction space, and low economic value, and improve the recovery of coal resources. The effect of reducing the cost of road retaining and saving loess resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

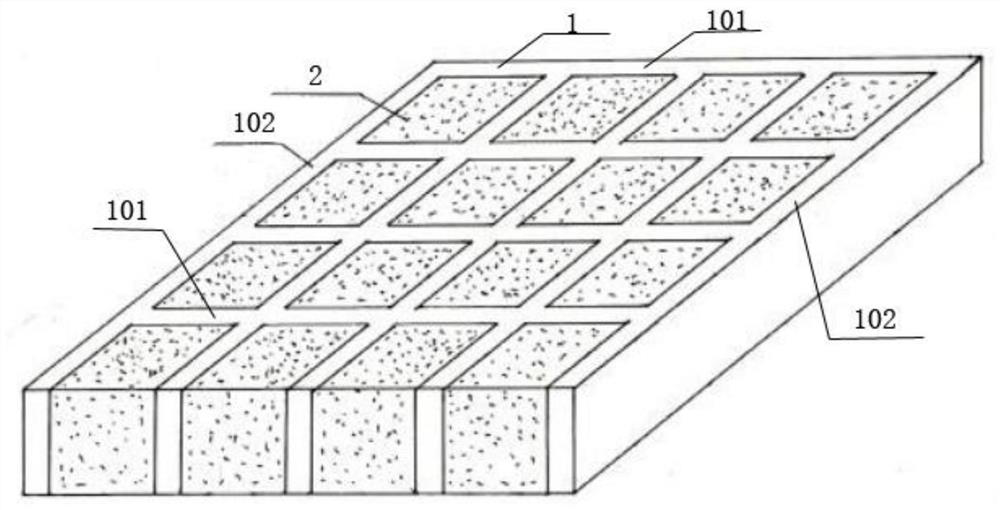

Image

Examples

preparation example Construction

[0052] (1) Preparation of coal gangue powder: The gangue screened by the dynamic sieve workshop and the gangue washed by the coal preparation workshop are transported to the gangue aggregate warehouse for buffering by belt conveyor, and then the gangue is transported to the coal mine by belt conveyor. In the gangue crushing workshop, after being crushed by the crusher, the gangue powder is transported to the gangue powder bin by the belt conveyor for standby.

[0053] (2) Pump the prepared material A solution into the solution storage tank for later use.

[0054] (3) Transport the prepared B material to the B material storage warehouse for standby.

[0055] So far, the production and preparation of materials have been completed.

[0056] 2. The material transportation part from the ground to the underground working face:

[0057] (1) Transportation of coal gangue powder: It should be determined on site according to different environmental conditions. Either use a spiral pip...

Embodiment approach

[0076] First, check that the spraying grouting pipeline used in the filling operation is unblocked, the water supply of the water pipe is normal, the valves are flexible to use, the mine filling wet spraying machine and the mine pneumatic grouting pump are working normally, and the filling materials are transported in place, etc.

[0077] Second, before the goaf filling operation, extend the side guards of the end frame hydraulic support in time to ensure that a separation wall is built between the top control area of the hydraulic support of the working face and the area to be filled (including the roadway).

[0078] Third, the filling operation adopts the operation method of moving and filling. That is, no matter which hydraulic support, as long as it moves forward, it will start to fill quickly.

[0079] Fourth, after the filling operation is completed (after the on-duty work is over), clean the mine pneumatic grouting pump and its attached spraying pipes and valves in ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com