Method for preparing bioactive coating on surface of 3D printed titanium or titanium alloy

A bioactive, 3D printing technology, used in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve problems such as inability to prepare ideal nanoscale structures and roughness, achieve excellent biological activity, enhance adhesion, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

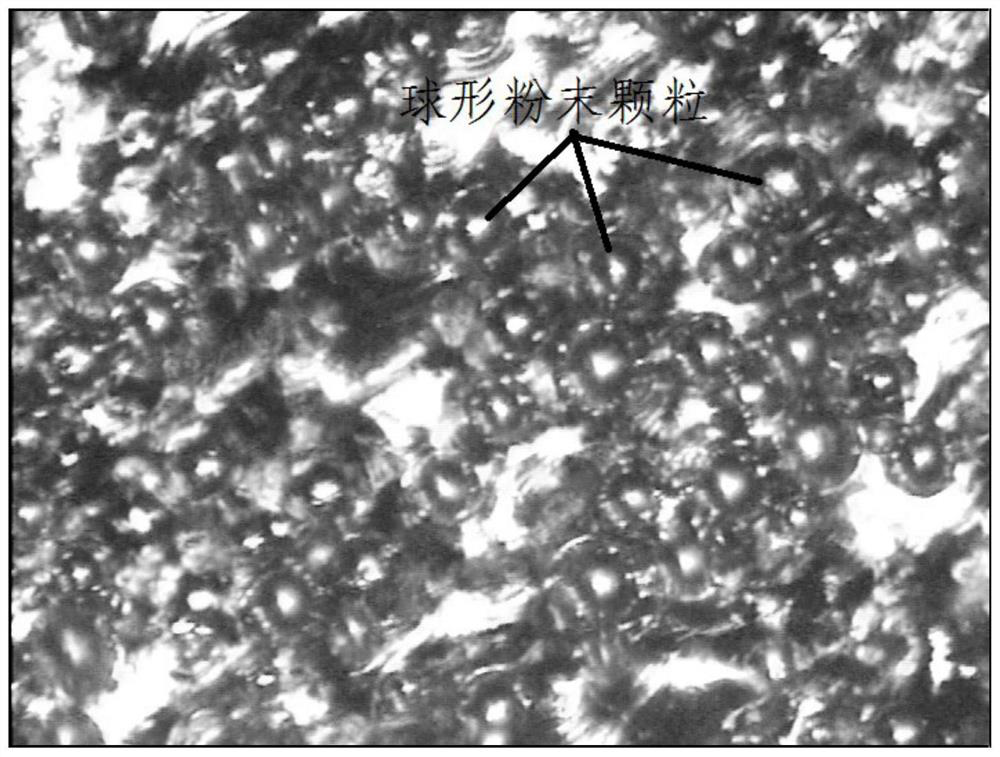

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

[0026] Step 1. Surface-treating the titanium alloy material to obtain the surface-treated titanium alloy material; the titanium alloy material is TC4 titanium alloy prepared by 3D printing; the surface treatment process is: cleaning the titanium alloy material with high-pressure water , and then perform etching treatment in an etching solution, then use running water to clean, and then dry in deionized water after ultrasonic; the pressure of the high-pressure water is 2MPa, and the time for high-pressure water cleaning is 10min, and the etching solution is made of HF solution, HNO with a mass ratio of 1:3:10 3 solution and deionized water, the mass concentration of the HF solution is 40%, the HNO 3 The mass concentration of the solution is 68%, the temperature of the etching treatment is 25° C., the time is 2 minutes, and the time of the ultrasonic treatment is 15 minutes;

[0027] Step 2. Perform anodic oxidation treatm...

Embodiment 2

[0051] This embodiment includes the following steps:

[0052] Step 1. Surface treatment is carried out on the titanium material to obtain the titanium material after surface treatment; the titanium material is TA2 titanium material prepared by 3D printing; the process of the surface treatment is: the titanium material is cleaned with high-pressure water, and then the Carry out etching treatment in the etching solution, then use running water to clean, and then dry after ultrasonic in deionized water; The pressure of the high-pressure water is 3MPa, and the time of high-pressure water cleaning is 5min, and the mass ratio of the etching solution is 1 : 5:12 HF solution, HNO 3 solution and deionized water, the mass concentration of the HF solution is 40%, the HNO 3 The mass concentration of the solution is 68%, the temperature of the etching treatment is 24° C., the time is 1 min, and the time of the ultrasonic treatment is 20 min;

[0053]Step 2. Anodizing the surface-treated ...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] Step 1. The titanium alloy material is subjected to surface treatment to obtain the titanium alloy material after surface treatment; the titanium alloy material is a TB2 titanium alloy material prepared by 3D printing; the surface treatment process is: the titanium alloy material is treated with high-pressure water After cleaning, etch in an etching solution, then wash with running water, and then dry in deionized water after ultrasonic; the pressure of the high-pressure water is 2.5MPa, and the time for high-pressure water cleaning is 8min. The solution consists of HF solution, HNO with a mass ratio of 1:4:11 3 solution and deionized water, the mass concentration of the HF solution is 40%, the HNO 3 The mass concentration of the solution is 68%, the temperature of the etching treatment is 26° C., the time is 1 min, and the time of the ultrasonic treatment is 30 min;

[0058] Step 2. Perform anodic oxidation treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com