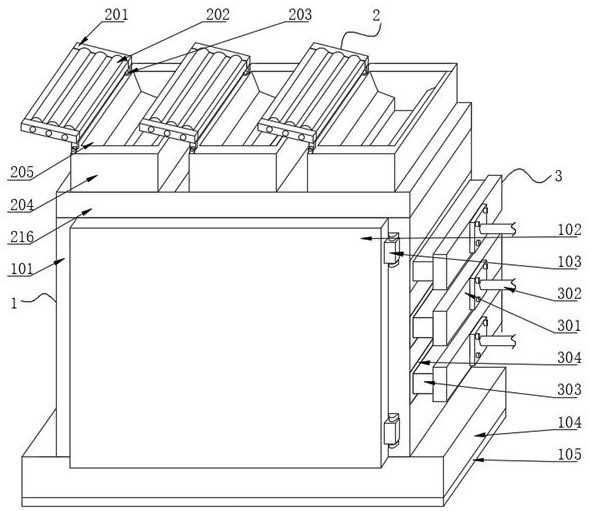

Steel stacking device for steel shearing machine processing

A shearing machine, steel technology, applied in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve problems such as inconvenience in shipping and recycling, and achieve the effects of improving placement stability, reducing noise, and reducing storage difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

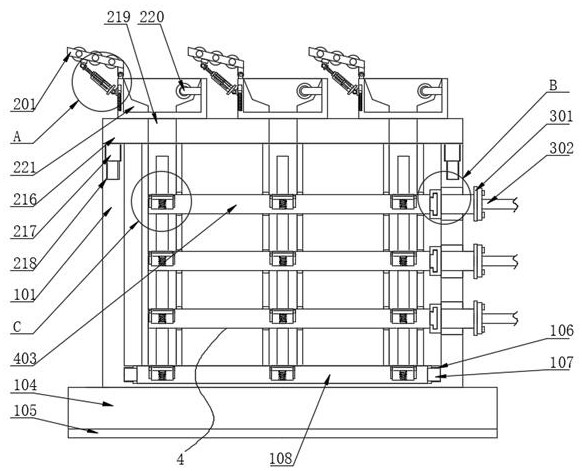

Method used

Image

Examples

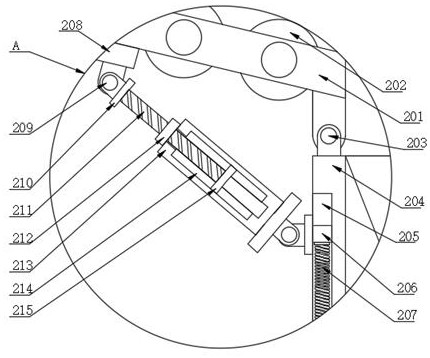

Embodiment approach

[0050] The specific embodiment is: when the component 405 falls into the top of the moving plate 108 or the top of the inserted support plate 403, the component 405 can be forced to drive the second sliding plate 407 at the bottom to slide in the fourth chute 409 through the third sliding blocks 410 on both sides, The second slide 407 is forced to squeeze the second spring 408, and the second spring 408 can absorb the impact force on the top of the second slide 407 by its own elastic force, and the backing plate 406 on the top of the second slide 407 can further absorb the fall of the member 405 by its own elastic force. impact when falling, and the base 104 and the bottom shock pad 105 can further absorb the impact force, reduce the noise transmitted from the contact surface, and improve the comfort of the working environment, thereby effectively reducing the impact force of the component 405 falling, and effectively improving the storage and stacking. stability.

[0051] Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com