Novel thermal deformation injection mold

An injection mold, thermal deformation technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using gas flow, etc., can solve problems such as damage to injection molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

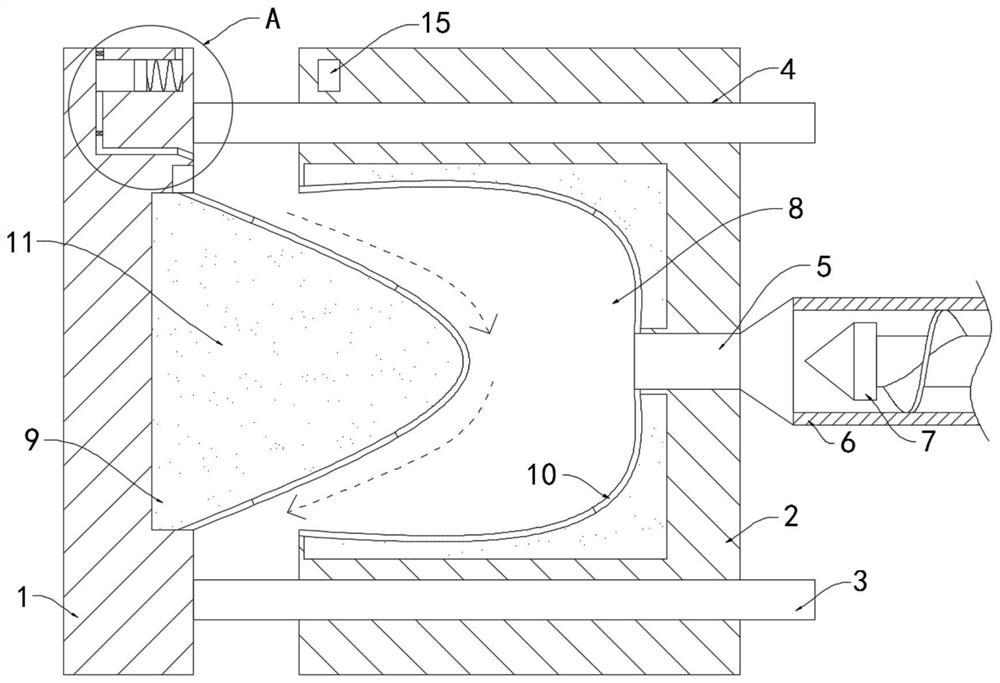

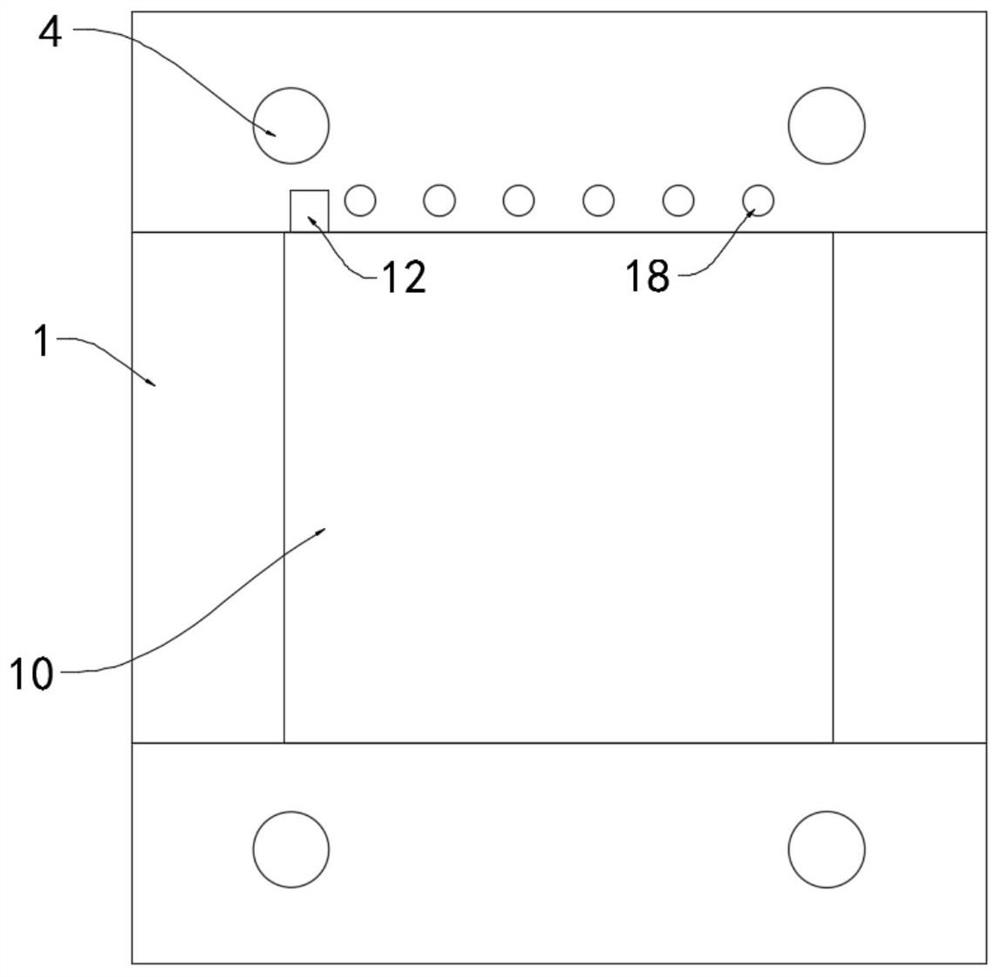

[0026] Such as Figure 1-4 As shown, a new thermal deformation injection mold includes a movable mold 1 and a fixed mold 2. The upper and lower ends of the inner wall of the movable mold 1 are fixedly connected with a plurality of horizontal positioning rods 3, and the side wall of the fixed mold 2 is provided with A plurality of positioning holes 4 corresponding to the positioning rods 3 one by one, the positioning rods 3 are slidingly connected to the positioning holes 4, the side wall of the fixed mold 2 is provided with an injection hole 5, the injection hole 5 is fixedly connected with an injection head 6, and the injection head 6 Be provided with turning roller 7 inside, all above are prior art.

[0027] The inner side wall of the fixed mold 2 is provided with a core groove 8, which forms a die. The inner side wall of the movable mold 1 and the inner side wall of the core groove 8 are all provided with a liquid tank 9, and each liquid tank 9 is filled with an electrorheo...

Embodiment 2

[0037] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a plurality of magnetic vibrating blocks 22 are fixedly embedded on the side wall of the memory metal thin layer 10, and a magnetic driving block is fixedly embedded on the side wall of the rotating roller 7. twenty three.

[0038] In this embodiment, the rotating roller 7 is always in a rotating state during the injection molding process, which will drive the magnetic drive block 23 to rotate rapidly. At this time, the magnetic force between the multiple magnetic vibration blocks 22 and the magnetic drive block 23 is constantly changing, so the magnetic vibration The block 22 will vibrate, and a plurality of magnetic vibration blocks 22 are arranged at the corners of the deformed memory metal thin layer 10, which can promote the full filling of the plastic solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com