Special machine tool for machining chutes of zigzag labyrinth sealing part

A technology of labyrinth seal and special machine tool, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, blind spots, difficult operation, etc., to improve processing efficiency, avoid mechanical errors, The effect of machining accuracy and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

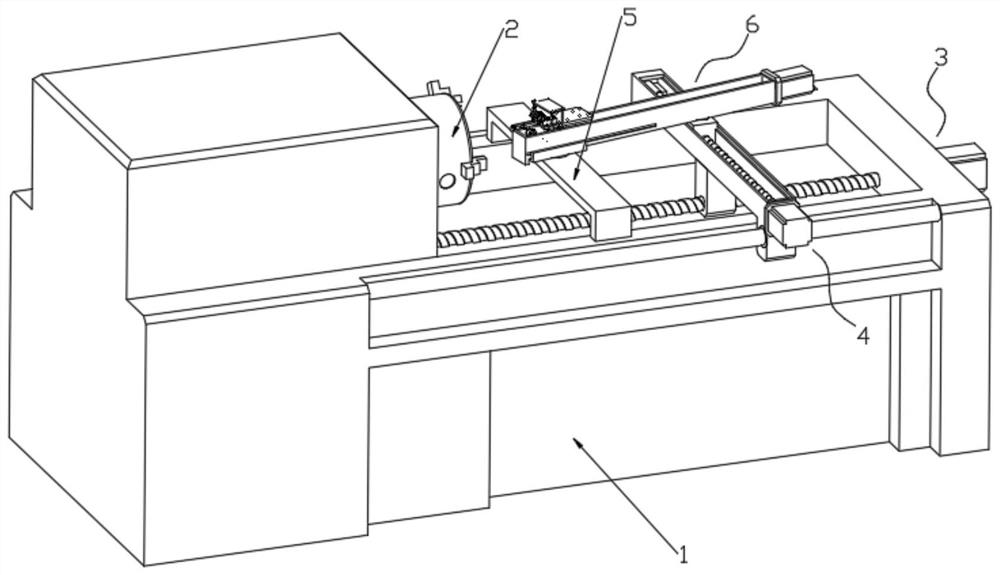

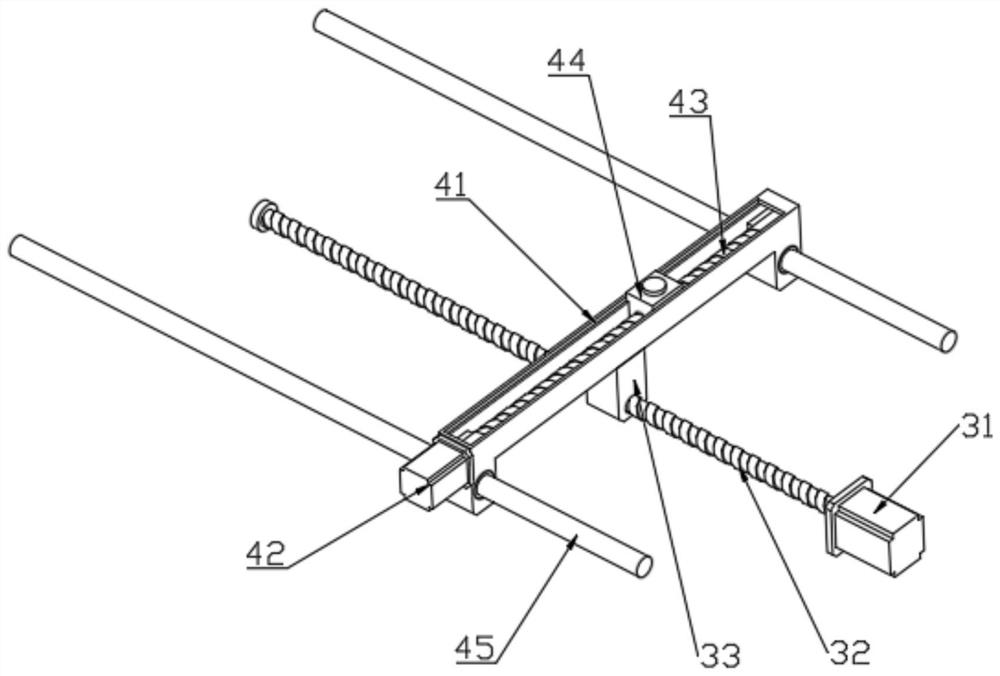

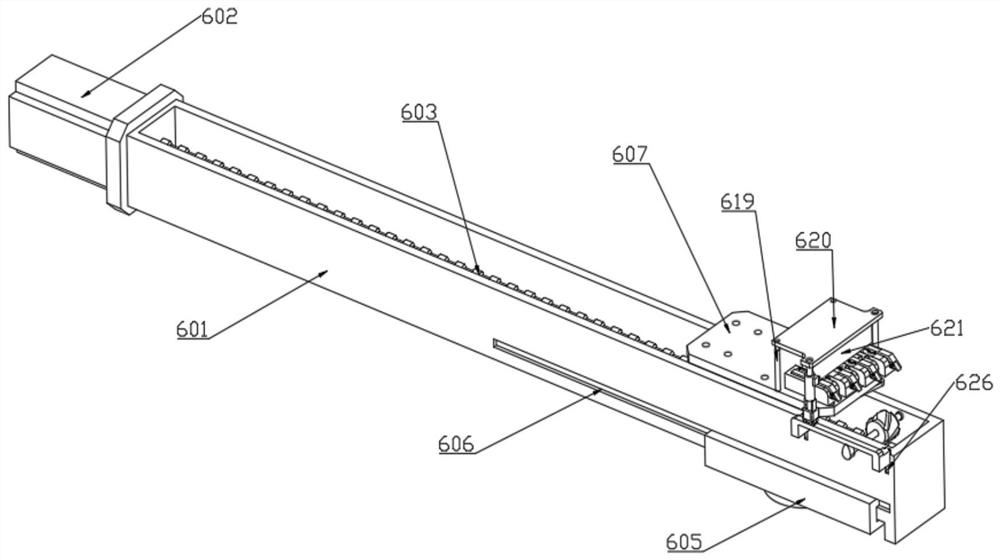

[0023] Such as Figure 1 to Figure 6 As shown, a special machine tool for machining inclined grooves of zigzag labyrinth sealing parts, including a body 1 and a chuck 2, the chuck 2 is installed on the body 1, and a first feeding mechanism is installed on the body 1 3. It is used to process the axial groove on the workpiece clamped on the chuck 2. The second feeding mechanism 4 is also installed on the body 1 to perform radial groove processing on the workpiece clamped on the chuck 2. For groove processing, a support frame 5 is fixedly arranged on the fuselage 1, a third feed mechanism 6 is installed on the upper end of the second feed mechanism 4, and the third feed mechanism 6 is rotatably arranged on the upper end of the support frame 5 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com