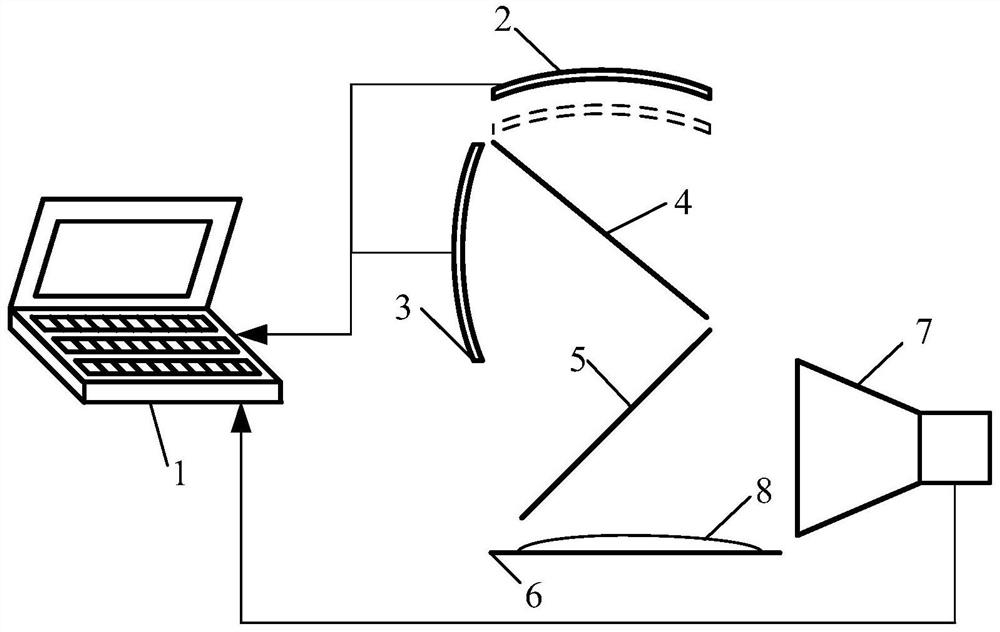

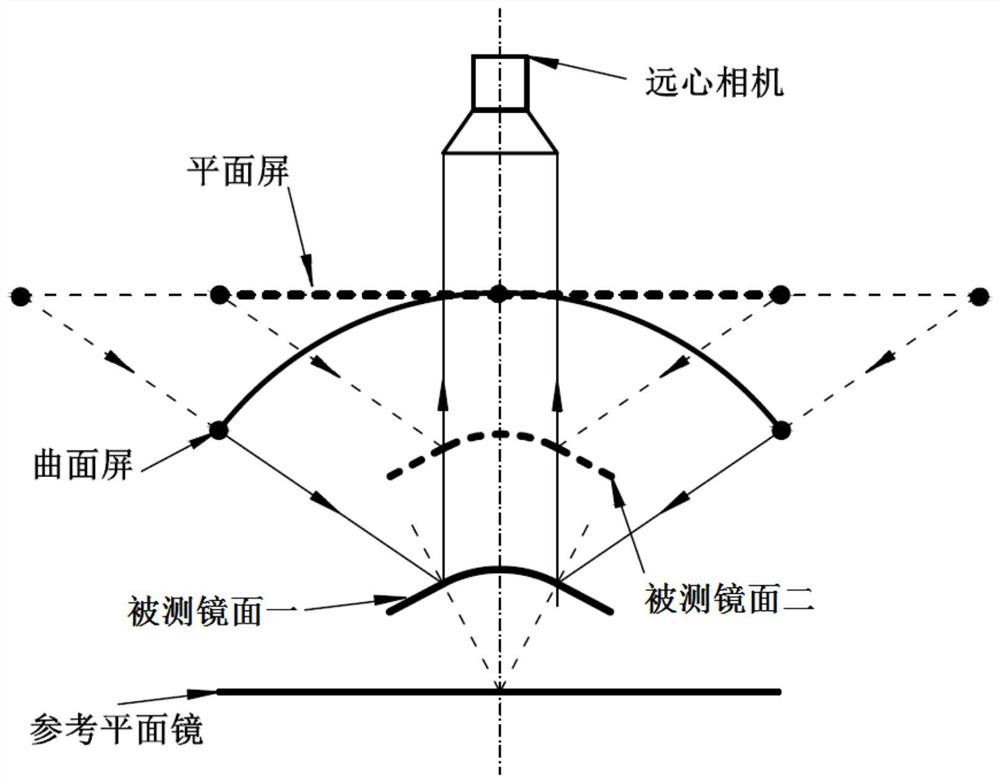

Three-dimensional shape measurement method of large curvature mirror based on phase deflection of curved screen

A measurement method and a technology of three-dimensional topography, which are applied in the direction of measuring devices, instruments, and optical devices, etc., can solve problems such as inability to measure three-dimensional mirror surfaces, inability to measure large height changes and gradient surface changes, and small curvature of mirror surfaces. Data processing time, convenient programming, and the effect of expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

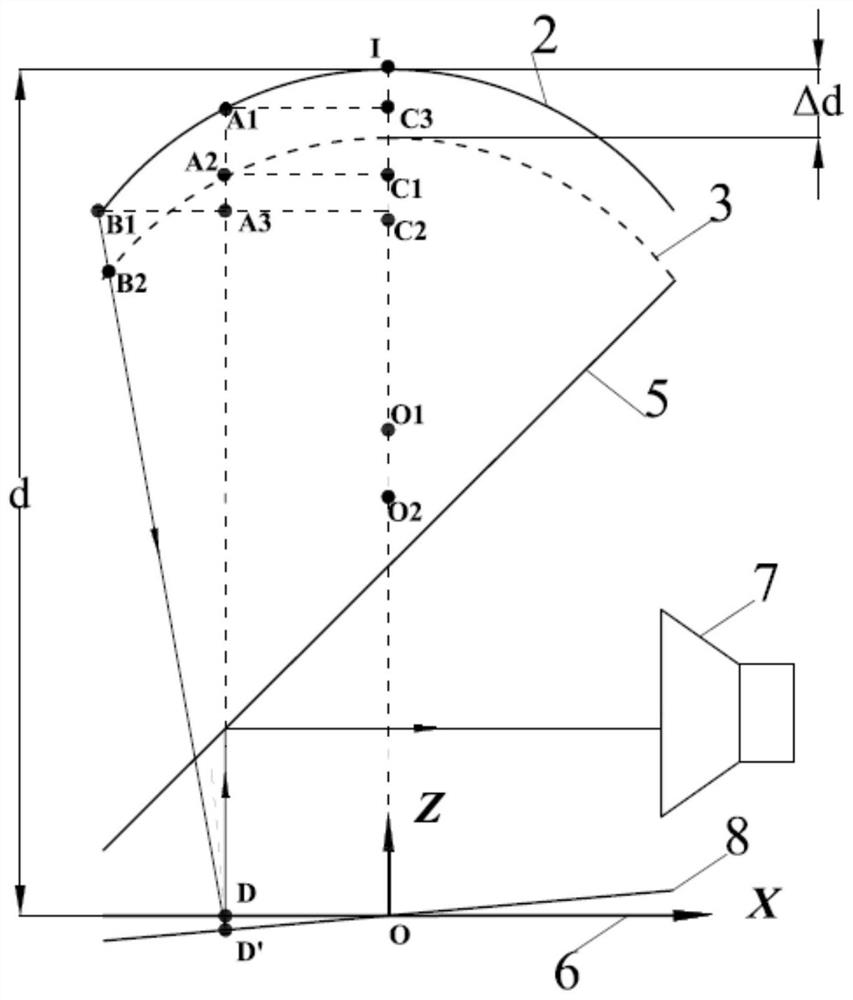

[0071] In this embodiment, the optimal three-stripe selection method used is a technique widely used in the field of structured light projection and reflection, and sinusoidal fringe patterns with 144, 143, and 132 fringes are selected.

[0072] In order to verify the correctness of the measurement method of the present invention, a simulation experiment was carried out to verify the method. This simulation experiment is programmed and run in MATLAB 2020a under the Windows platform. The simulation parameters are as follows:

[0073] The distances between the virtual image vertices of the first curved screen 2 and the second curved screen 3 and the reference plane mirror 6 are 115.2000 mm and 21.1200 mm, respectively. Both the first curved screen 2 and the second curved screen 3 have a radius of 768.000 mm, a resolution of 1536*2048, and a pixel size of 0.0960 mm. The telecentric camera 7 has a magnification of 0.0570, a CCD resolution of 2050*2448, and a pixel size of 3.4500u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com