LED lamp tube inner wall cleaning device

A technology of LED lamp tube and cleaning device, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that debris cannot be cleaned and removed sufficiently and efficiently, and achieve excellent cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

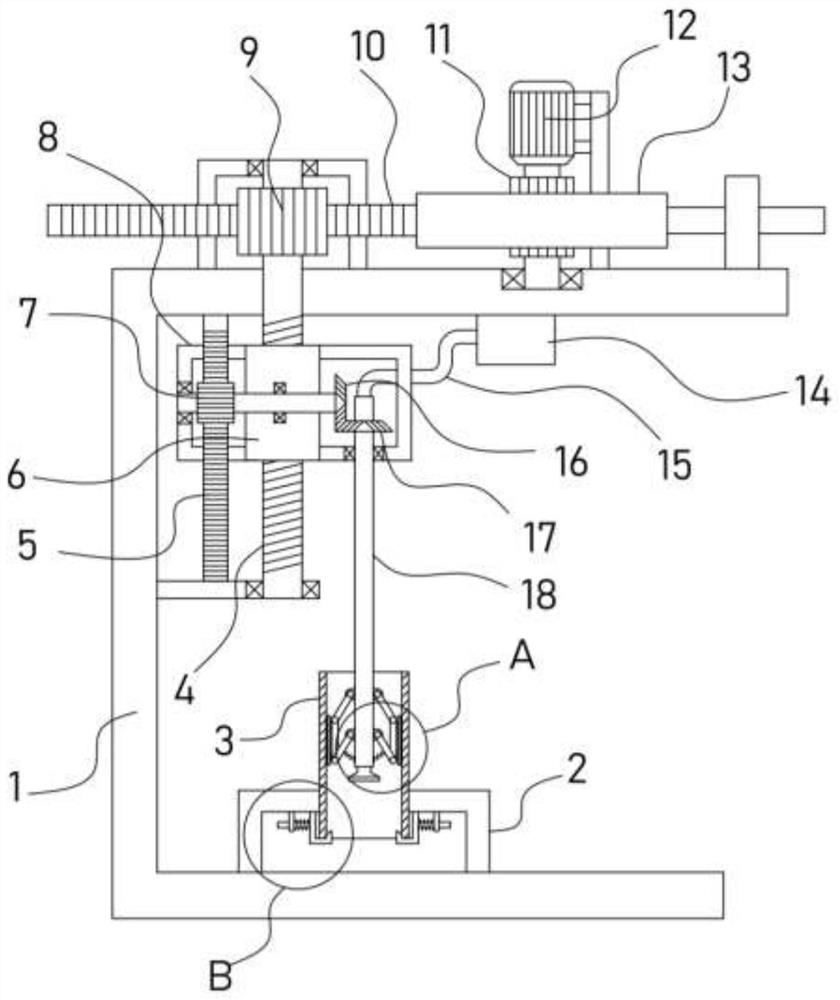

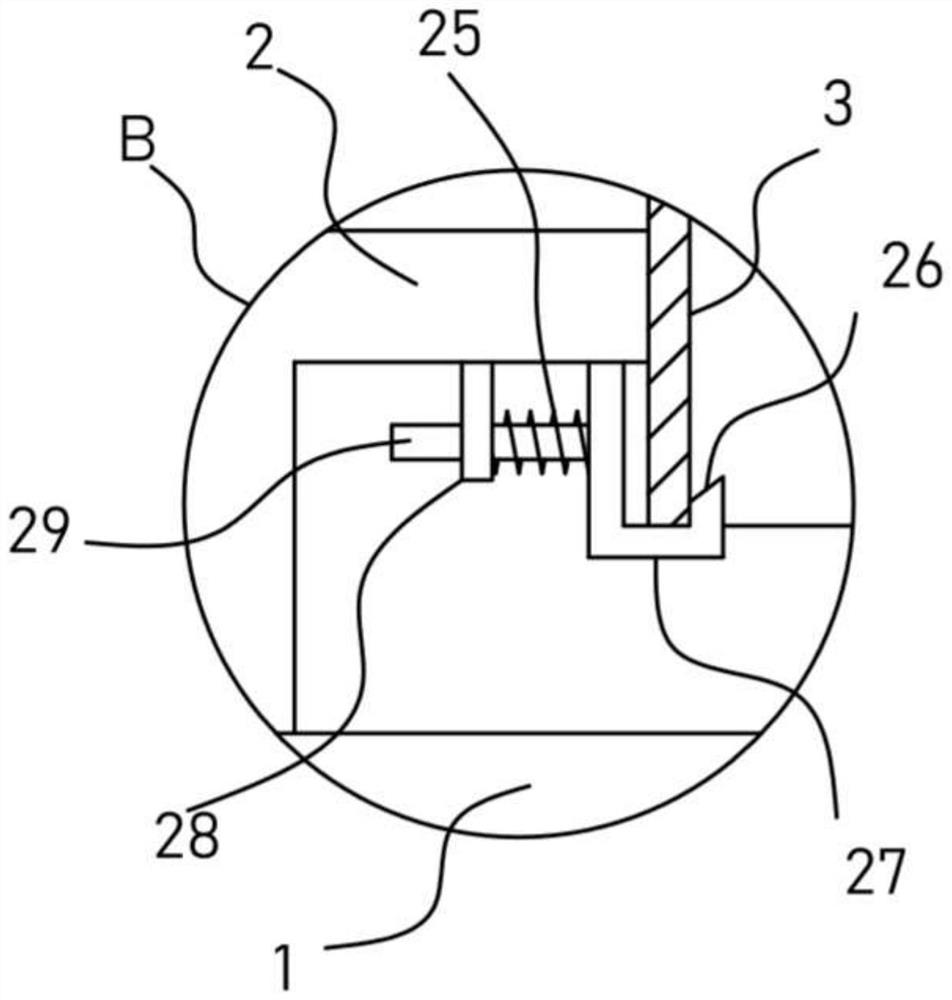

[0023] see Figure 1-4 , a device for cleaning the inner wall of an LED lamp tube, comprising a fixed frame 1, a support frame 2 is fixed on the fixed frame 1, a pair of clamping mechanisms for fixing the lamp tube 3 are arranged on the support frame 2, and the fixed frame 1 A drive motor 12 is fixed on the drive motor 12, and the drive motor 12 is connected with a horizontal reciprocating translation mechanism. The thread sleeve is connected with a threaded sleeve 6, and the threaded sleeve 6 is provided with a rotating mechanism, and a cleaning mechanism for cleaning the inner wall of the lamp tube 3 is installed on the rotating mechanism.

[0024] The lateral reciprocating translation mechanism provided in the device includes a lateral rack 10 which is slidably mounted on the top of the fixed frame 1 , and the lateral rack 10 is meshed with a drive gear 9 sleeved and fixed on the threaded column 4 . The horizontal reciprocating translation mechanism also includes a circula...

Embodiment 2

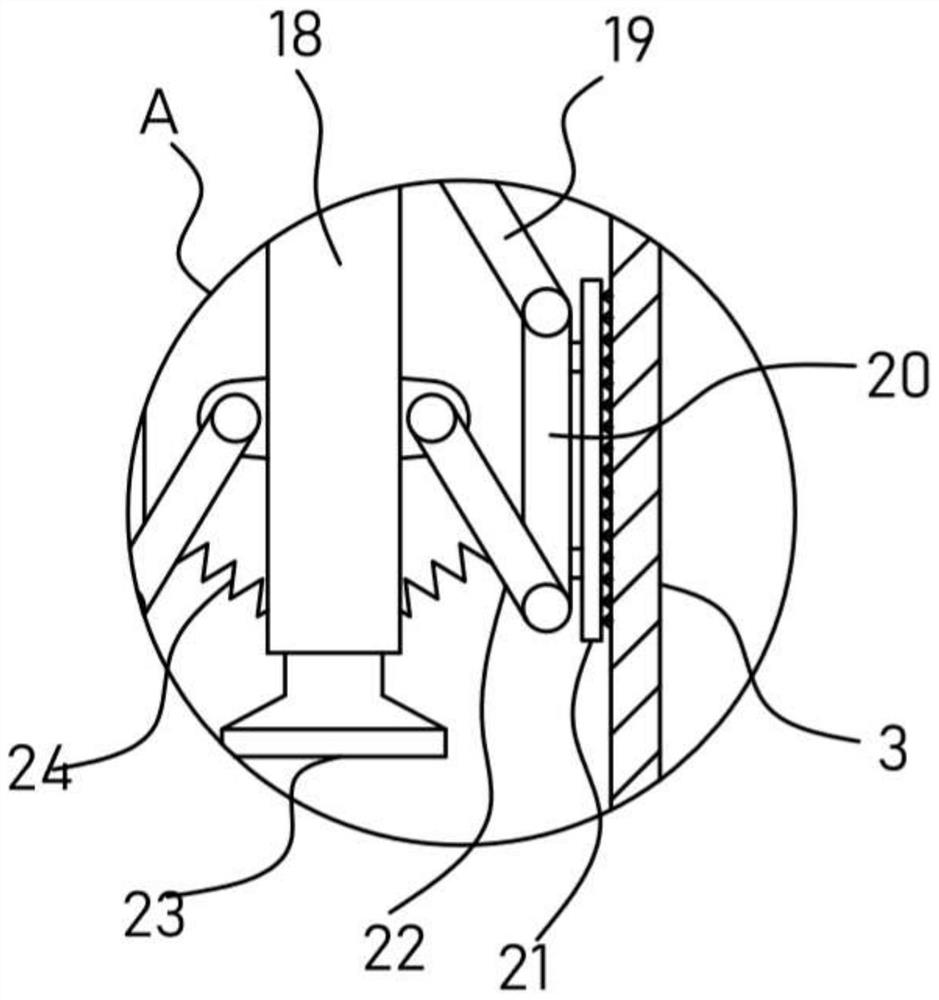

[0029] On the basis of Embodiment 1, in addition, the cleaning mechanism of this device comprises two connecting mechanisms installed on the side wall of the hollow rotating shaft 18, and each connecting mechanism comprises parallel and equal-length articulated rods I19 hinged on the hollow rotating shaft 18 and The hinged rod II22, the hinged rod I19 and the hinged rod II22 are hinged with a vertically arranged vertical plate 20, and the vertical plate 20 is fixed with a brush plate 21 in contact with the inner wall of the lamp tube 3. The hinged rod II22 is connected with the hollow shaft 18 is hinged with push-off spring 24.

[0030] The hinged rod I19 and the hinged rod II22 provided can rotate synchronously, so that the two can drive the vertical plate 20 to move laterally while maintaining the vertical state under the elastic push action of the push spring 24, and then realize that the brush plate 21 fits on the The inner wall of the lamp tube 3 realizes the effect of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com