High-performance graphene/nylon 6 alloy and preparation method thereof

A graphene, high-performance technology, applied in the field of polymer material alloy preparation, can solve the problems of unsatisfactory performance of composite materials, insufficient dry toughness, poor resistance to strong acid and strong alkali, etc., to achieve easy industrial continuous production and wide application Prospects, high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

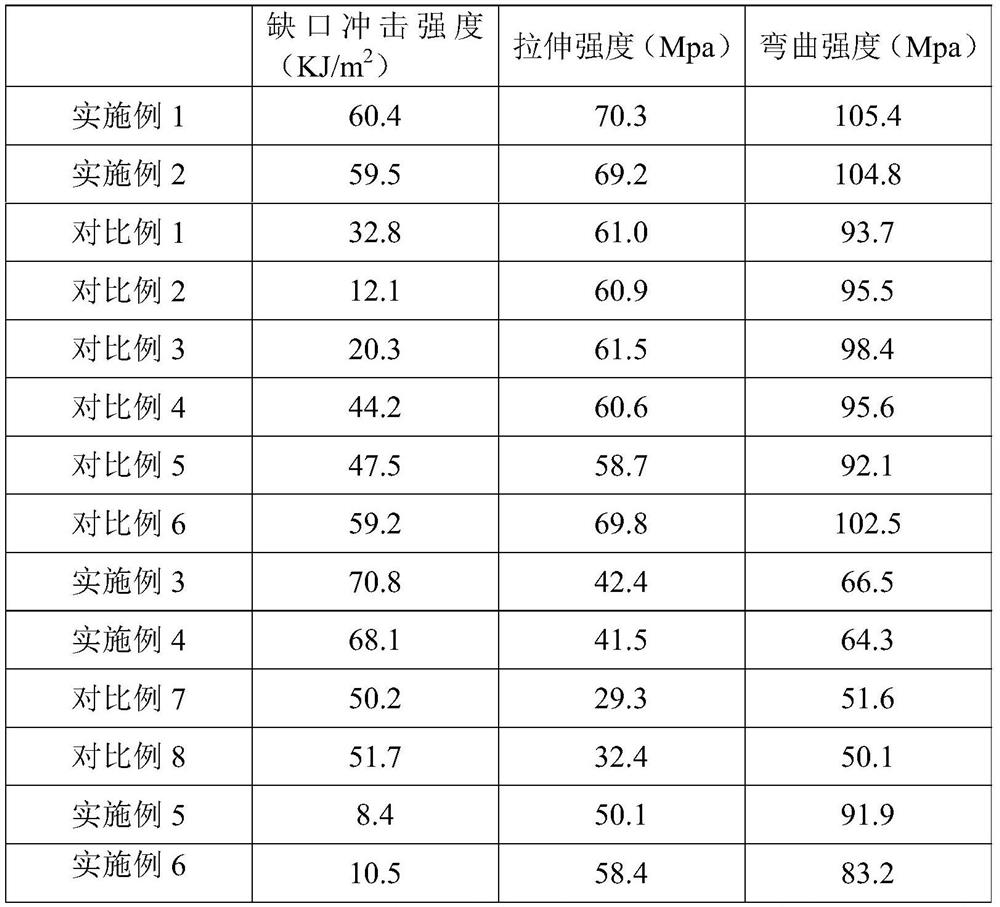

Examples

Embodiment 1

[0036] (1) According to the mass ratio of 3:2, the graphene oxide solution with a concentration of 1% is mixed evenly with the caprolactam powder, and the excess water is removed through vacuum distillation to obtain a uniform mixed solution;

[0037] (2) Transfer the homogeneous mixed solution prepared in step (1) to the polymerization reactor, stir at 50-200r / min, and heat up to 260°C, keep the pressure at 0.2-2MPa for 4 hours, and discharge the air in the reactor. Vacuumize to 6000Pa, react for 1 hour, keep warm for 1.5 hours, release the material and cool it down;

[0038](3) extract the material cooled in step (2) in boiling water for 12 hours, change the water and repeat 3 times, discharge the unreacted caprolactam in the system, place it in a vacuum oven to dry, extrude and granulate to obtain graphene / nylon 6 Resin, the mass percent composition of graphene oxide in described graphene / nylon 6 resin is 1.9%;

[0039] (4) Graphene / nylon 6 resin and nylon 6 obtained by st...

Embodiment 2

[0043] (1) According to the mass ratio of 3:5, the graphene oxide solution with a concentration of 2% and the caprolactam powder are mixed evenly, and excess water is removed through vacuum distillation to obtain a uniform mixed solution;

[0044] (2) Transfer the homogeneous mixed solution prepared in step (1) to the polymerization reactor, stir at 50-200r / min, and heat up to 260°C, keep the pressure at 0.2-2MPa for 4 hours, and discharge the air in the reactor. Vacuumize to 6000Pa, react for 1 hour, keep warm for 1.5 hours, release the material and cool it down;

[0045] (3) extract the material cooled in step (2) in boiling water for 12 hours, change the water and repeat 3 times, discharge the unreacted caprolactam in the system, place it in a vacuum oven to dry, extrude and granulate to obtain graphene / nylon 6 Resin, the mass percent composition of graphene oxide in described graphene / nylon 6 resin is 1.5%;

[0046] (4) get the graphene / nylon 6 resin and nylon 6 that step...

Embodiment 3

[0050] According to the weight ratio of 4:5, the graphene oxide solution with a concentration of 1.5% and the caprolactam powder are mixed evenly, and the excess water is removed by vacuum distillation to obtain a uniform mixed solution;

[0051] (2) Transfer the homogeneous mixed solution prepared in step (1) to the polymerization reactor, stir at 50-200r / min, and heat up to 260°C, keep the pressure at 0.2-2MPa for 4 hours, and discharge the air in the reactor. Vacuumize to 6000Pa, react for 1 hour, keep warm for 1.5 hours, release the material and cool it down;

[0052] (3) extract the material cooled in step (2) in boiling water for 16 hours, change the water and repeat 4 times, discharge the unreacted caprolactam in the system, place it in a vacuum oven to dry, extrude and granulate to obtain graphene / nylon 6 Resin, the mass percent composition of graphene oxide in described graphene / nylon 6 resin is 2.1%;

[0053] (4) get the graphene / nylon 6 resin and nylon 6 that step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com