Forming method for prefabricated hollow wallboard

A technology of hollow wall panels and panels, applied in the direction of manufacturing tools, ceramic molding machines, ceramic extrusion dies, etc., can solve the problems of surface water and groundwater pollution, affect air quality, occupy land, etc., achieve great economy and reduce burden , The effect of saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

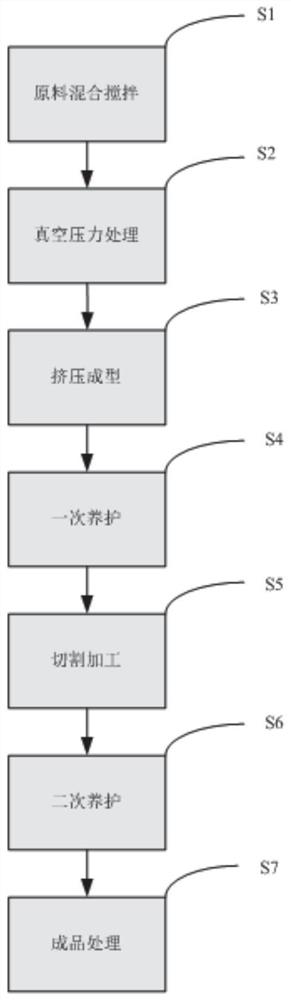

[0033] The embodiment of the invention discloses that the invention discloses a method for forming a prefabricated hollow wall panel, which includes the following steps:

[0034] Step S1: stirring the siliceous material including natural stone powder, cement and fiber;

[0035] Step S2: The stirred material is pressurized in a vacuum state to enhance the compactness of the plate;

[0036] Step S3: extruding through special or custom-made molds, and adjusting different molds to achieve different shapes of plates;

[0037] Step S4: The extruded forming board enters the curing kiln for a curing to make it harden gradually;

[0038] Step S5: Carry out cutting and processing according to the design or customer's size requirements for the plate;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com