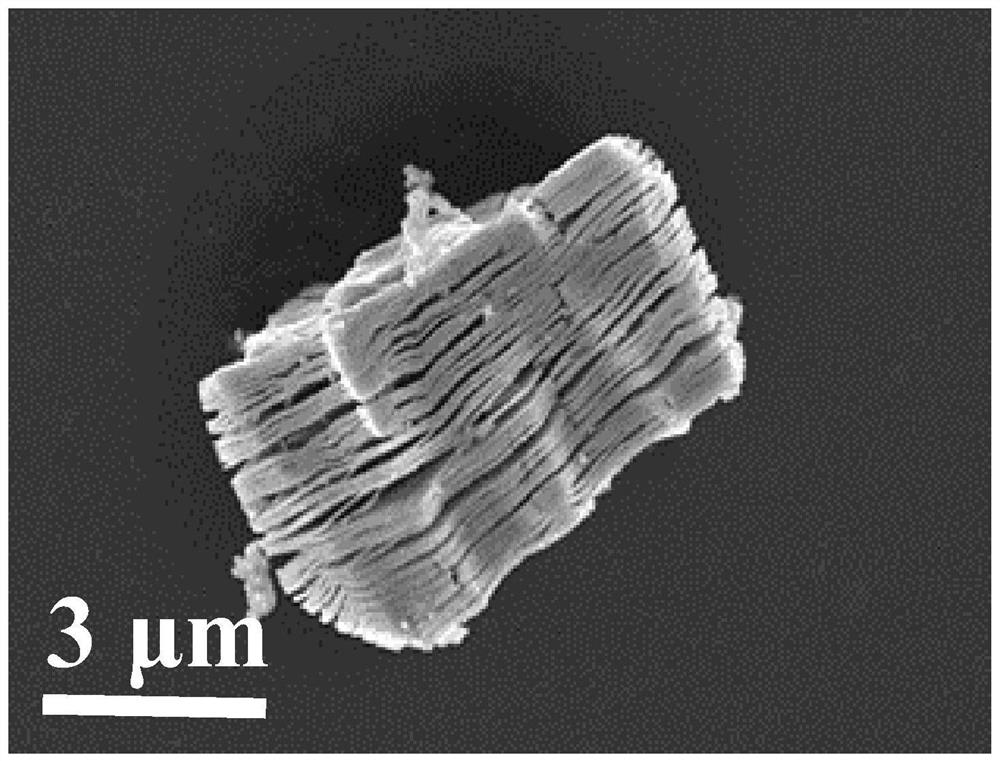

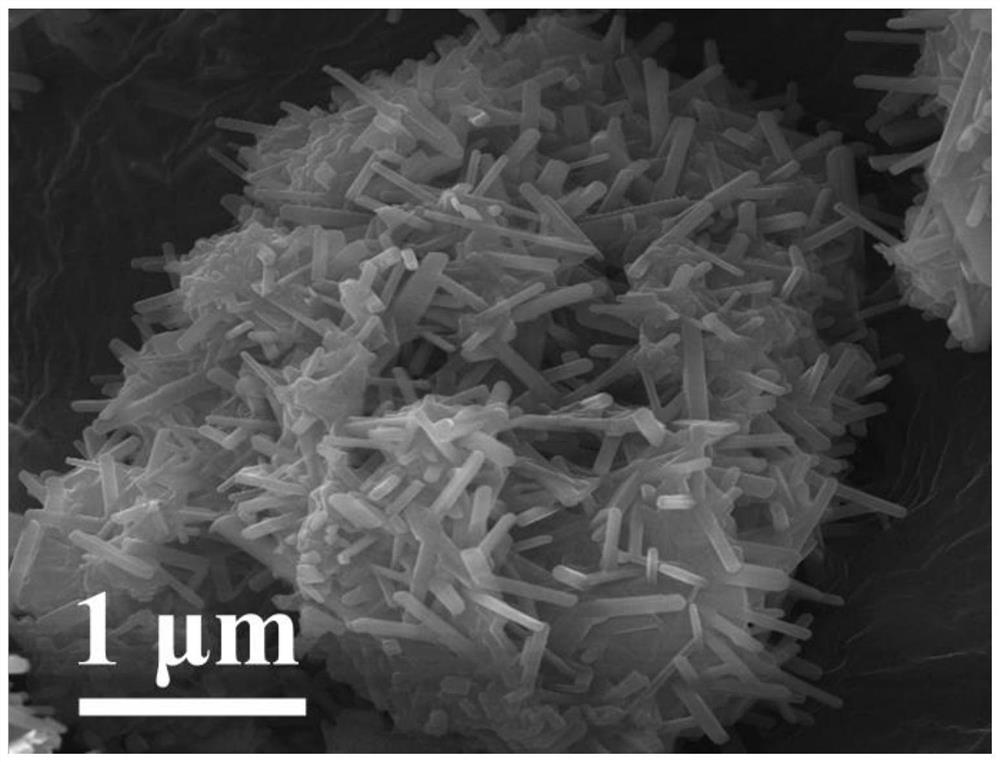

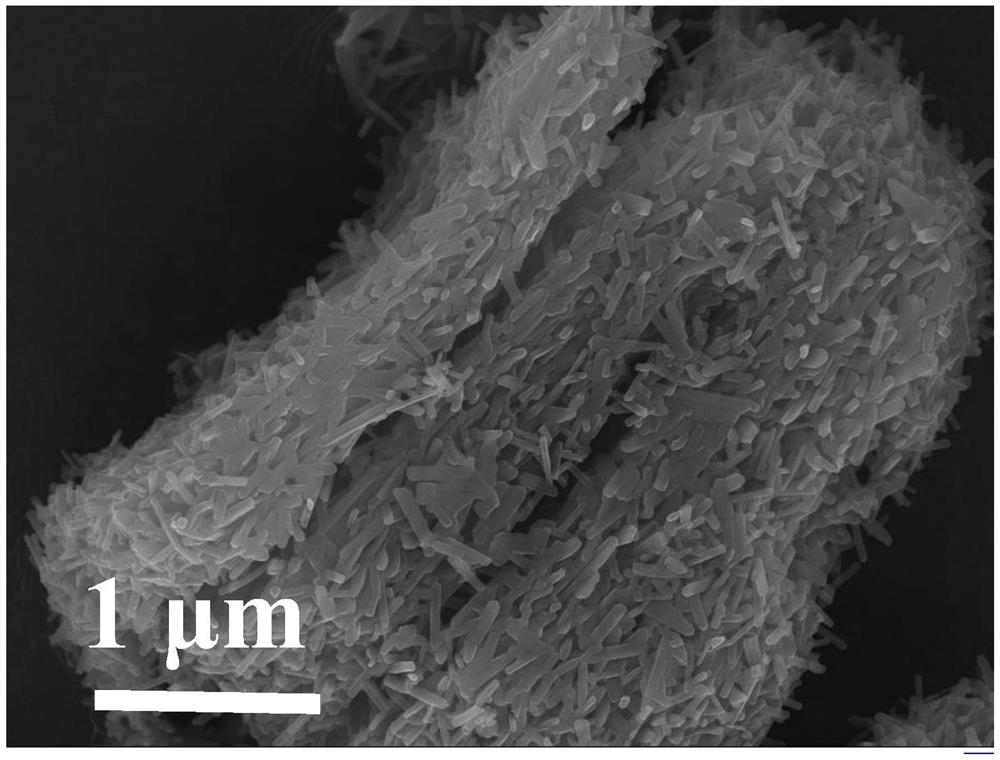

Preparation method of three-dimensional rod-like potassium titanate material

A potassium titanate, rod-shaped technology is applied in the field of preparation of three-dimensional rod-shaped potassium titanate materials, which can solve the problems of unfavorable potassium ion battery performance, poor uniformity of potassium titanate, and easy to agglomerate, and achieves suitable for large-scale application and good storage. Potassium properties, the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a three-dimensional rod-shaped potassium titanate material, comprising the following steps:

[0039] (1) Potassium hydroxide is added in the solvent, is configured as the potassium hydroxide solution that concentration is 1mol / L;

[0040] (2) 100mg Ti 3 C 2 T x Add the potassium hydroxide aqueous solution that 50ml step (1) makes, then stir 12 hours with the stirring speed of 650r / min;

[0041] (3) The product obtained in step (2) is centrifuged at a speed of 6500r / min, and then alternately washed 3 times with ethanol and ultrapure water;

[0042] (4) drying the centrifuged product obtained in step (3) in a vacuum drying oven at a temperature of 70° C. for 12 hours to obtain a precursor;

[0043] (5) After putting the precursor obtained in step (4) into a corundum crucible, transfer it to a tube furnace;

[0044] (6) Heat the tube furnace to 1000°C at a heating rate of 3°C / min in an air atmosphere, keep it warm for 1.5 hours and then cool to ...

Embodiment 2

[0048] A method for preparing a three-dimensional rod-shaped potassium titanate material, comprising the following steps:

[0049] (1) Potassium hydroxide is added in the solvent, is configured as the potassium hydroxide solution that concentration is 3mol / L;

[0050] (2) 300mg Ti 3 C 2 T x Add the potassium hydroxide aqueous solution that 50ml step (1) makes, then stir 8 hours with the stirring speed of 800r / min;

[0051] (3) The product obtained in step (2) is centrifuged at a speed of 5000r / min, and then alternately washed 3 times with ethanol and ultrapure water;

[0052] (4) drying the centrifuged product obtained in step (3) in a vacuum drying oven at a temperature of 80° C. for 10 hours to obtain a precursor;

[0053] (5) After putting the precursor obtained in step (4) into a corundum crucible, transfer it to a tube furnace;

[0054] (6) Heat the tube furnace to 800°C at a heating rate of 4°C / min in an air atmosphere, keep it warm for 3 hours and then cool to room...

Embodiment 3

[0058] A method for preparing a three-dimensional rod-shaped potassium titanate material, comprising the following steps:

[0059] (1) Potassium hydroxide is added in the solvent, is configured as the potassium hydroxide solution that concentration is 5mol / L;

[0060] (2) 1000mg Ti 3 C 2 T x Add the potassium hydroxide aqueous solution that 80ml step (1) makes, then stir 8 hours with the stirring velocity of 800r / min;

[0061] (3) The product obtained in step (2) is centrifuged at a speed of 7000r / min, and then alternately washed 5 times with ethanol and ultrapure water;

[0062] (4) vacuum drying the centrifuged product obtained in step (3) at a temperature of 60°C for 14 hours to obtain a precursor;

[0063] (5) After putting the precursor obtained in step (4) into a corundum crucible, transfer it to a tube furnace;

[0064] (6) Heat the tube furnace to 900°C at a heating rate of 5°C / min in an air atmosphere, keep it warm for 4 hours and then cool to room temperature; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com