Preparation method and detection method of corrosion-resistant medical magnet

A corrosion resistance and detection method technology, applied in the fields of weather resistance/light resistance/corrosion resistance, inductor/transformer/magnet manufacturing, permanent magnet, etc. Corrosion and other issues to achieve the effect of avoiding medical risks, good biocompatibility, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of corrosion-resistant medical magnet of the present invention, it comprises the steps:

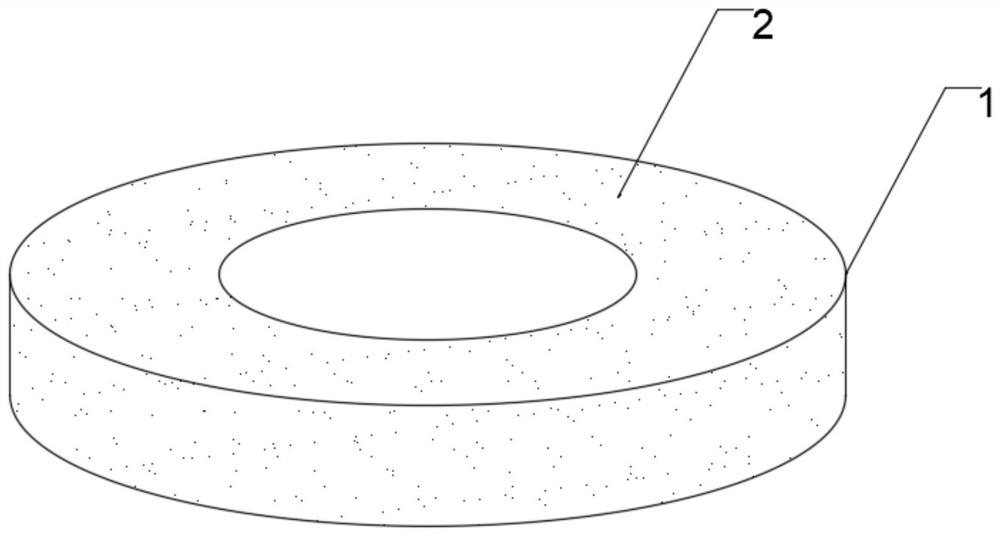

[0031] 1) Choose a ring-shaped unmagnetized N45 NdFeB as the magnet body, and round the corners of the magnet body;

[0032] 2) Soak the above-mentioned rounded magnet body in an acid solution for pickling, remove the rust on the surface of the magnet and take it out;

[0033] 3) Utilize physical vapor deposition to form a coating layer on the surface of the magnet body in step 2), to obtain a coating magnet; the coating layer is a 10um parylene coating;

[0034] 4) After the coated magnet is cooled, magnetize it with a magnetizer to obtain a corrosion-resistant medical magnet.

Embodiment 2

[0036] A kind of preparation method of corrosion-resistant medical magnet of the present invention, it comprises the steps:

[0037] 1) Choose a ring-shaped unmagnetized N45 NdFeB as the magnet body, and round the corners of the magnet body;

[0038] 2) Soak the above-mentioned rounded magnet body in an acid solution for pickling, remove the rust on the surface of the magnet and take it out;

[0039] 3) Utilize physical vapor deposition to form a coating layer on the surface of the magnet body in step 2), to obtain a coating magnet; the coating layer is a 25um parylene coating;

[0040] 4) After the coated magnet is cooled, magnetize it with a magnetizer to obtain a corrosion-resistant medical magnet.

Embodiment 3

[0042] A kind of preparation method of corrosion-resistant medical magnet of the present invention, it comprises the steps:

[0043] 1) Choose a ring-shaped unmagnetized N45 NdFeB as the magnet body, and round the corners of the magnet body;

[0044] 2) Soak the above-mentioned rounded magnet body in an acid solution for pickling, remove the rust on the surface of the magnet and take it out;

[0045] 3) Utilize physical vapor deposition to form a coating layer on the surface of the magnet body in step 2), to obtain a coating magnet; the coating layer is a 30um parylene coating;

[0046] 4) After the coated magnet is cooled, magnetize it with a magnetizer to obtain a corrosion-resistant medical magnet.

[0047] As the best embodiment, a method for preparing a corrosion-resistant medical magnet of the present invention, the coating layer is a 25um parylene coating, and parylene C powder is selected as the coating raw material.

[0048] As the best embodiment, a kind of prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com