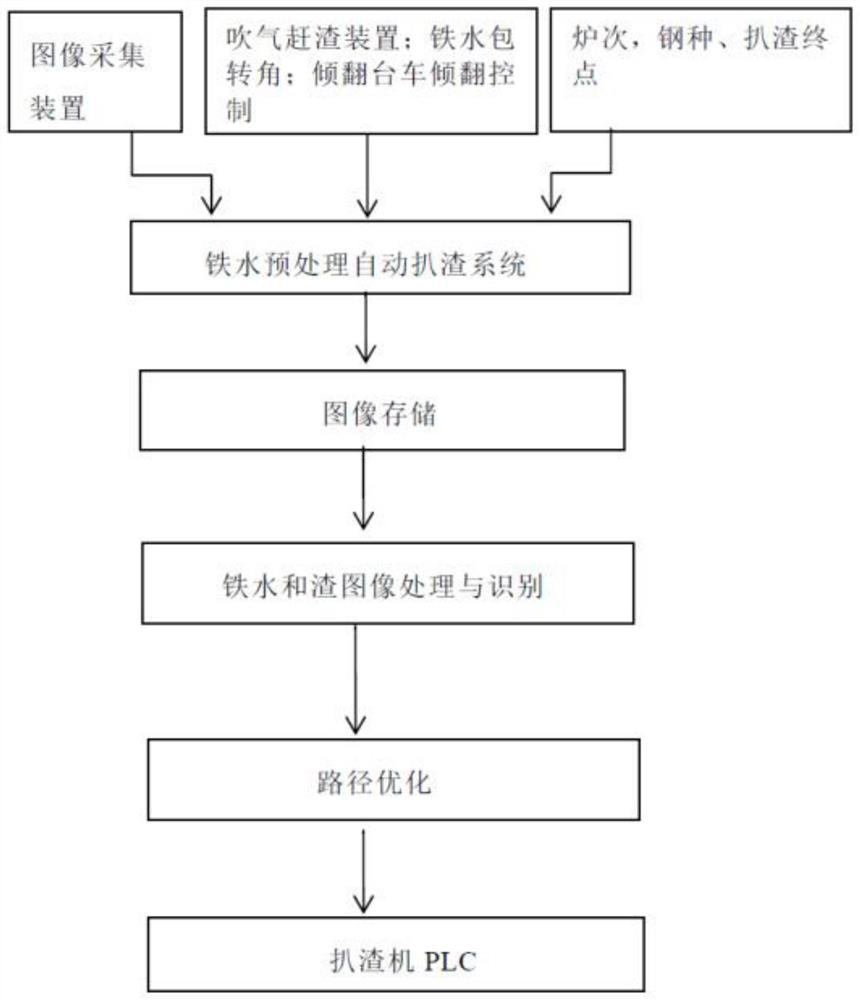

Efficient molten iron pretreatment automatic slagging-off method and system

A technology of molten iron pretreatment and molten iron slag, which is applied in image data processing, energy efficiency improvement, steel manufacturing process, etc., can solve the problems that do not involve slag removal efficiency, shorten the slag removal time, increase production capacity, and increase the number of furnaces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The high-efficiency molten iron pretreatment automatic slagging method and system of the present invention will be further described according to the specific embodiments of the present invention and the accompanying drawings, but the description does not constitute an improper limitation of the present invention.

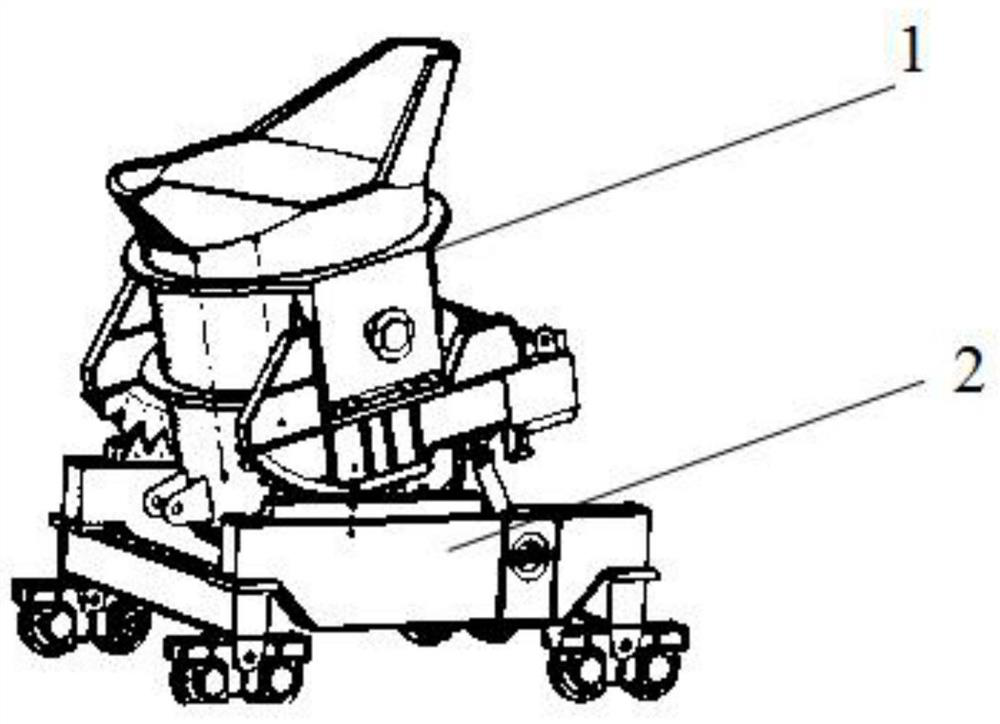

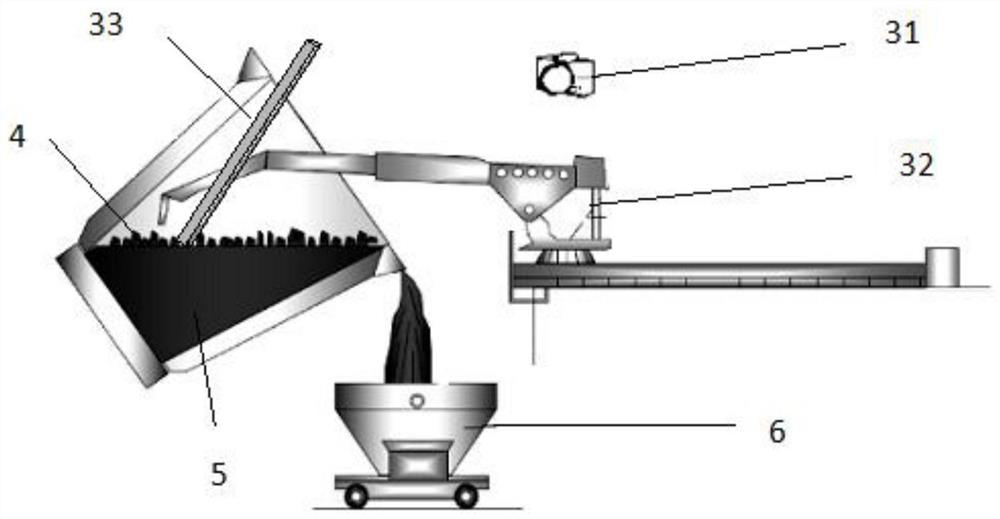

[0055] figure 1 It is a structural schematic diagram of a slagging device in an embodiment of the efficient automatic slagging method for molten iron pretreatment according to the present invention.

[0056] Such as figure 1 As shown, after the ladle 1 is lifted to the seat frame of the tilting trolley 2 by driving, the slag removal starts. When removing slag, first tilt the trolley 2 so that the ladle 1 is tilted from the vertical position to the slag removing position at a certain angle to the ground. The tilting angle can be measured by adding an inclinometer or by installing an encoder on the rotating shaft of the tilting trolley 2 .

[0057] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com