Self-powered integrated hydraulic oil cylinder

A hydraulic cylinder and power technology, which is applied in the field of self-powered integrated hydraulic cylinder, can solve the problems of scattered configuration, many parts, large hydraulic system volume, etc., and achieve the reduction of hydraulic drive mechanism, less leakage points, and reduced land occupation The effect of area and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

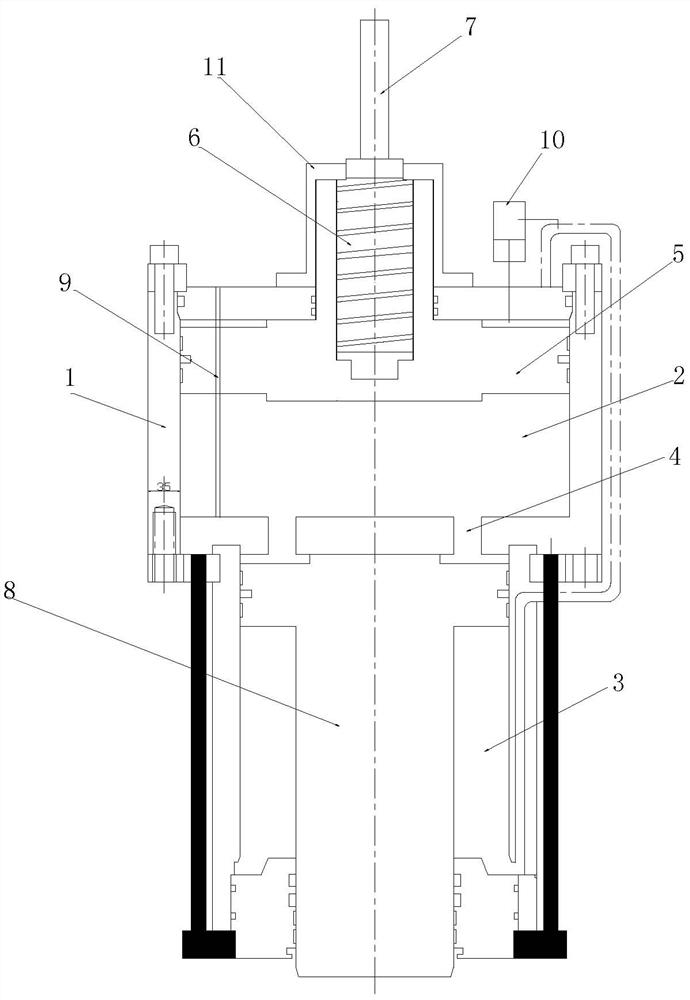

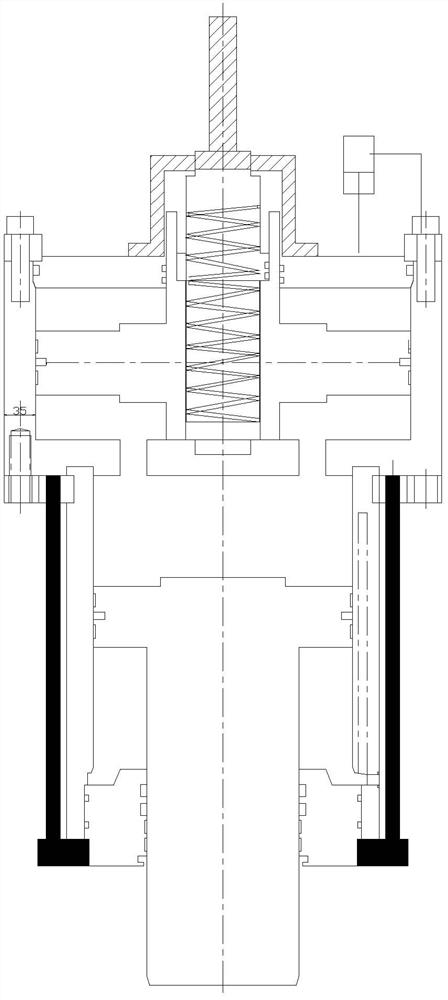

[0020] Such as figure 1 shown.

[0021] A self-powered integrated hydraulic oil cylinder, which includes a cylinder body 1, such as figure 1 As shown, the cylinder body is composed of a pressure generating chamber 2 filled with hydraulic oil and a power output chamber 3. The pressure generating chamber 2 and the power output chamber 3 are connected through a through hole 4. The pressure generating chamber 2 is installed There is a piston 5, which divides the pressure generating chamber into a high-pressure chamber and a low-pressure chamber. The center of the piston 5 is provided with a screw hole, and a screw 6 is installed in the screw hole. It is connected with the output shaft 7 of the servo motor (or other motors); in order to prevent the rotation of the piston 5 and reduce wear and tear, the piston 5 can realize its linear movement in the pressure generating chamber 2 by adding an anti-rotation mechanism during specific implementation. The grinding performance is good ...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that the axis of the T-shaped piston rod 8 is installed eccentrically with the axis of the piston 5 .

Embodiment 3

[0026] The difference between this embodiment and Embodiment 1 is that the axis line of the T-shaped piston rod 8 is installed perpendicular to the axis of the piston 5. At this time, it is only necessary to connect a transition cylinder on the cylindrical surface of the pressure generating chamber 2, and pass through the transition cylinder. It is enough to realize the communication between the pressure generating chamber 2 and the power output chamber 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com