Efficient resource utilization method of red mud

A resource recovery and red mud technology, applied in the direction of improving process efficiency, can solve problems such as low solubility, risk of dam collapse, release of alkaline substances to pollute the environment, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

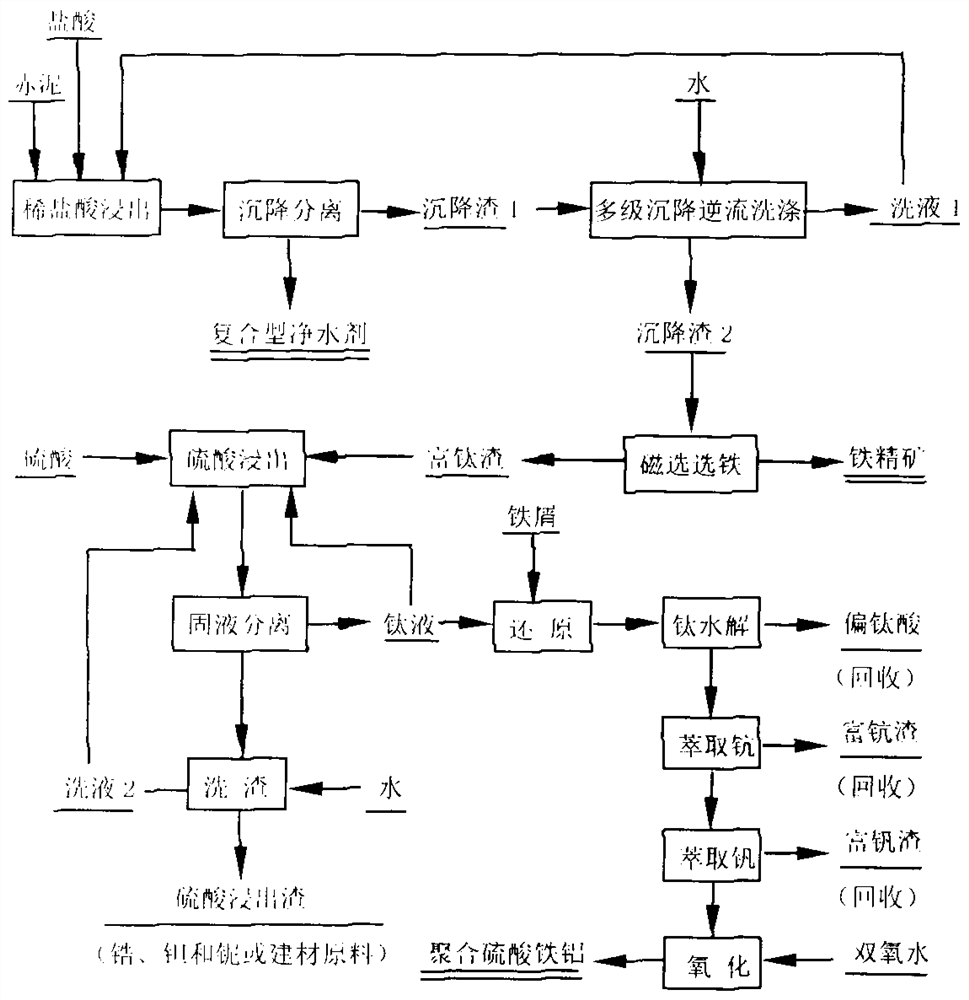

[0023] Such as figure 1 As shown, a method for efficient resource utilization of red mud of the present invention comprises the following steps:

[0024] 1. Dilute the concentrated hydrochloric acid to 1.5mol / L with lotion 1, and the initial liquid-solid ratio (ml / g) is 6. After reacting for 15 minutes, add red mud while adding concentrated hydrochloric acid until the total liquid-solid ratio is 4.5. The reaction temperature is 20-60° C., the reaction time is 1.0 h, and the final pH value of the solution is 1.0.

[0025] 2. The acidic pulp obtained in the first step above is separated by a thickener, and the upper overflow is used as a composite water purifier product, and the solid water purifier product is obtained after drying. Perform countercurrent washing with a five-stage thickener to obtain sedimentation 2 and washing solution 1 enriched in iron, titanium, scandium and vanadium.

[0026] 3. Sedimentary slag 2 uses a pulsating high-gradient magnetic separator to selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com