Two-component water-based long-acting anti-icing coating

An anti-icing, two-component technology, which is applied in the direction of fire-resistant coatings, coatings, and other chemical processes, can solve the problems of hydrophobic damage on the coating surface and insufficient durability of anti-icing on the coating surface, so as to reduce storage loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

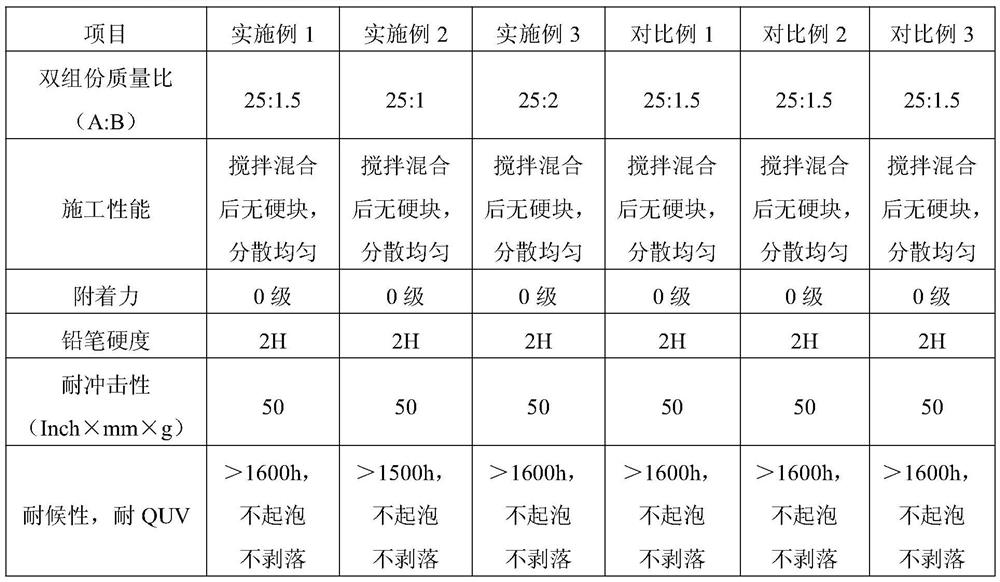

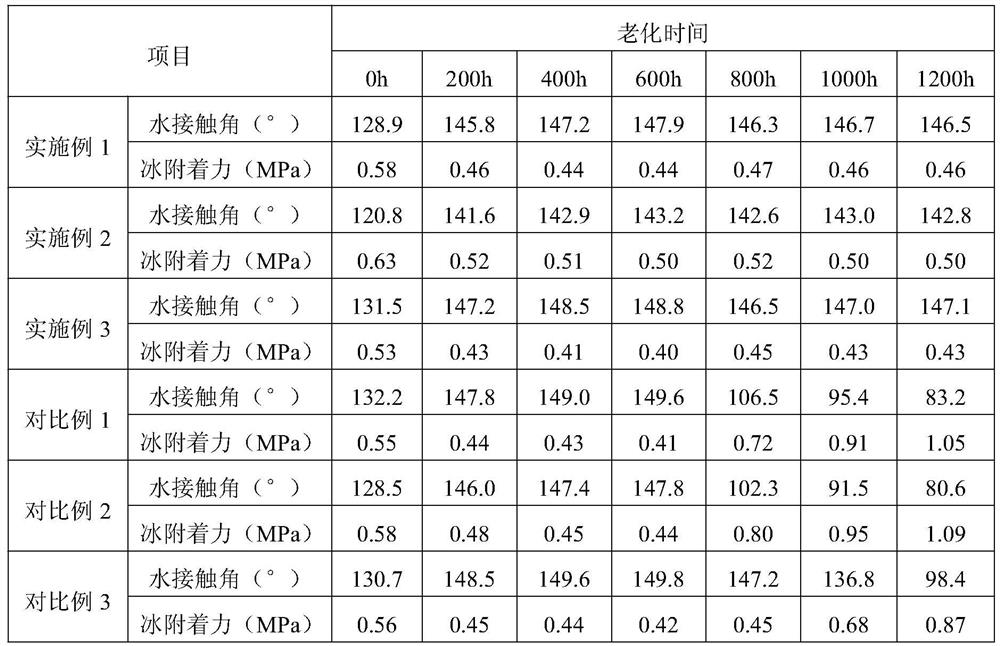

Examples

Embodiment 1

[0036] A two-component water-based long-lasting anti-icing coating, including independently packaged components A and B; the raw materials of component A include in parts by weight: 95 parts of silicone rubber emulsion, 8 parts of n-tetradecane, 10 parts of fumed silica, 8 parts of silicon micropowder, 0.8 part of dibutyltin dilaurate, 3 parts of leveling agent, 0.3 part of defoamer, 4 parts of sodium carbonate, 60 parts of water; the raw materials of component B are calculated in parts by weight Including: 30 parts of methyltriacetoxysilane, 20 parts of γ-aminopropyltriethoxysilane, 20 parts of silicone oil sustained-release particles.

[0037] Wherein the preparation method of silicone oil sustained-release particles comprises the following steps:

[0038] (1) Dissolve P123 in absolute ethanol, add butyl titanate dropwise under stirring, and then add a mixed solution of ethanol and water dropwise after stirring for 40 minutes, and obtain a precursor solution after stirring f...

Embodiment 2

[0046] A two-component water-based long-lasting anti-icing coating, including independently packaged component A and component B; the raw materials of component A include in parts by weight: 90 parts of silicone rubber emulsion, 5 parts of n-tetradecane, 15 parts of fumed white carbon black, 0.5 part of dibutyltin dilaurate, 1 part of leveling agent, 0.2 part of defoamer, 3 parts of sodium carbonate, 50 parts of water; the raw materials of component B include in parts by weight: 20 parts of four Ethoxysilane, 10 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 10 parts of silicone oil sustained-release particles.

[0047] Wherein the preparation method of silicone oil sustained-release particles comprises the following steps:

[0048] (1) Dissolve P123 in absolute ethanol, add butyl titanate dropwise under stirring, and then add the mixed solution of ethanol and water dropwise after stirring for 30 minutes. After stirring for 1 hour, a precursor solution is obtained, in wh...

Embodiment 3

[0056] A two-component water-based long-lasting anti-icing coating, including independently packaged component A and component B; the raw materials of component A include in parts by weight: 100 parts of silicone rubber emulsion, 10 parts of n-tetradecane, 15 parts of fumed silica, 5 parts of wollastonite, 1 part of dibutyltin dilaurate, 5 parts of leveling agent, 0.4 part of defoamer, 5 parts of sodium carbonate, 70 parts of water; the raw materials of component B are in parts by weight It includes: 40 parts of tetraethoxysilane, 30 parts of γ-glycidyl etheroxypropyl trimethoxysilane, and 30 parts of silicone oil sustained-release particles.

[0057] Wherein the preparation method of silicone oil sustained-release particles comprises the following steps:

[0058] (1) Dissolve P123 in absolute ethanol, add butyl titanate dropwise under stirring, and then add a mixed solution of ethanol and water dropwise after stirring for 60 minutes. After stirring for 2 hours, a precursor so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com