Device and method for repairing soil with organic matter-heavy metal combined contamination

A compound pollution and soil remediation technology, which is applied in the remediation of organic matter and heavy metal compound polluted soil and soil remediation, can solve the problems of ineffective removal and transfer of pollutants, difficulty in large-scale promotion of electric technology, and unsuitable remediation, etc., to achieve solidification Good effect, easy operation, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

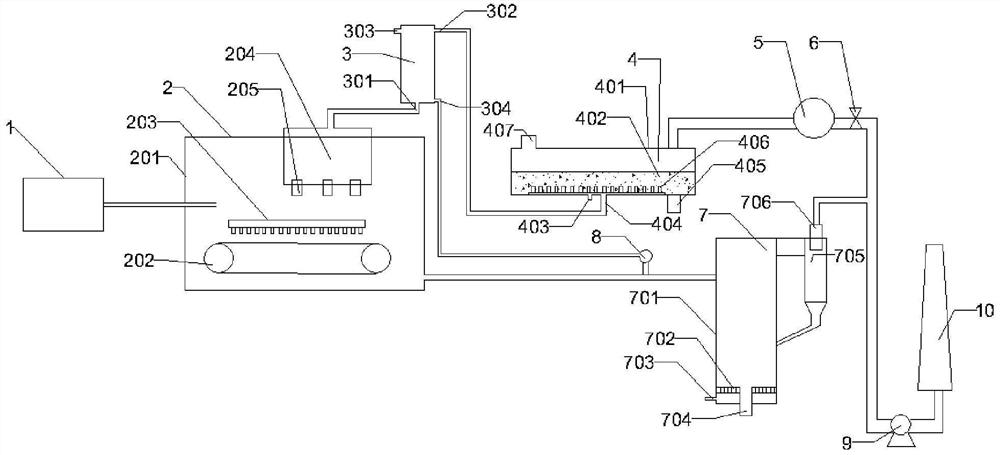

[0107] This embodiment provides a device for remediation of organic matter-heavy metal compound polluted soil, such as figure 1 As shown, the device includes a crushing unit 1, a microwave unit 2, an oxidation unit 3, an activation unit 4 and a flue gas treatment unit connected in sequence; the microwave unit 2 includes a microwave device; the microwave unit 2 also includes a The first gas outlet on the upper part of the device and the first soil outlet arranged on the lower part of the microwave device; the first gas outlet is connected to the oxidation unit 3; the device also includes a fluidized reaction unit connected to the first soil outlet; The fluidized reaction unit is connected with the flue gas treatment unit.

[0108] Described microwave unit 2 comprises microwave cover 201 and is arranged on microwave cavity 204 at one end of microwave cover 201; The top of described microwave cavity 204 is connected with microwave generator (not shown); The top of described micro...

Embodiment 2

[0114] This embodiment provides a device for repairing organic matter-heavy metal composite polluted soil, the device includes a crushing unit, a microwave unit, an oxidation unit, an activation unit, and a flue gas treatment unit connected in sequence; the microwave unit includes a microwave device; the The microwave unit also includes a first gas outlet arranged on the upper part of the microwave device and a first soil outlet arranged on the lower part of the microwave device; the first gas outlet is connected to the oxidation unit; the device also includes a gas outlet connected to the first soil outlet A fluidized reaction unit; the fluidized reaction unit is connected with the flue gas treatment unit.

[0115] The microwave unit includes a microwave cover and a microwave cavity arranged at one end of the microwave cover; a microwave generating device is connected to the upper part of the microwave cavity; a first gas outlet is provided at the top of the microwave cavity; ...

Embodiment 3

[0121] This embodiment provides a device for remediating organic matter-heavy metal compound polluted soil. The device is the same as that of Embodiment 1 except that the first dosing device is set as a dosing tube arranged at the upper front end of the conveyor belt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com