Catalyst Pd/Nb2C and preparation method and application thereof

A catalyst and carrier technology, applied in the field of catalyst Pd/Nb2C and its preparation, can solve the problems of large energy consumption, poor economic benefits, unfavorable development, etc., and achieve the effects of low energy consumption, good mechanical strength, and simple loading mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

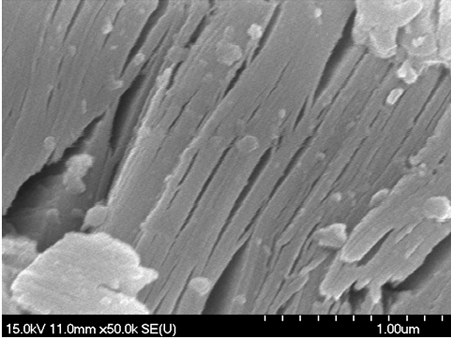

[0032] 5 wt. % hydrofluoric acid etching Nb 2 Preparation of Nb from AlC 2 C, including the following steps:

[0033] Weigh 1.5g of Nb 2 AlC was placed in a 50mL polytetrafluoroethylene reactor, 5mL of 5 wt.% hydrofluoric acid was added, stirred at room temperature for 12h, ultrasonicated at a power of 350W for 3h, and then the precipitate was treated with water and ethanol at a volume ratio of 1:1 Filter and wash 3 times, add 5 mL of DMSO to the washed sample, and stir at room temperature for 12 h. Then wash by centrifugation, the washing condition is 5000rpm, wash 5min, repeat 3 times. These precipitates were soaked in 5 mL of deionized water, and then sonicated at 350 W for 2 h. Washed 5 times by a 1:1 mixture of water and ethanol, freeze-dried to obtain the final Nb 2 C-1.

Embodiment 2

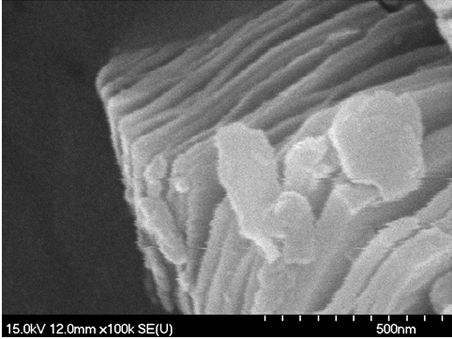

[0035] 40 wt. % hydrofluoric acid etching Nb 2 Preparation of Nb from AlC 2 C, including the following steps:

[0036] Weigh 1.5g of Nb 2 AlC was placed in a 50mL polytetrafluoroethylene reactor, 20mL of 40wt.% hydrofluoric acid was added and stirred at room temperature for 48h, and the power was sonicated at 700W for 1h, and then the precipitate was treated with water and ethanol at a volume ratio of 1:1 Filter and wash 5 times, add 20 mL of DMSO to the washed sample, and stir at room temperature for 24 h. Then wash by centrifugation, the washing condition is 7500rpm, 10min, repeated 5 times. These precipitates were soaked in 20 mL of deionized water, and then sonicated at 500 W for 0.5 h. Washed 5 times by a 1:1 mixture of water and ethanol, freeze-dried to obtain the final Nb 2 C-2.

Embodiment 3

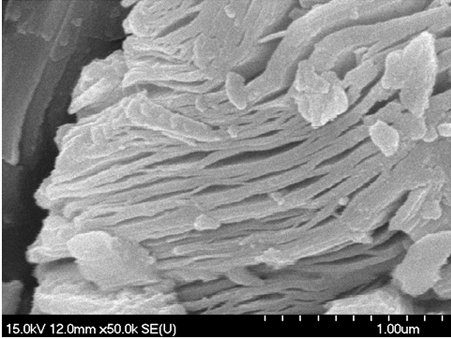

[0038] 50 wt. % hydrofluoric acid etching Nb 2 Preparation of Nb from AlC 2 C, including the following steps:

[0039] Weigh 1.5g of Nb 2 AlC was placed in a 50mL polytetrafluoroethylene reactor, and 50mL of 50wt.% hydrofluoric acid was added and stirred at room temperature for 72h, ultrasonically 0.5h at a power of 1000W, and then the precipitate was treated with water and ethanol at a volume ratio of 1:1 Filter and wash 8 times, add 50 mL of DMSO to the washed sample, and stir at room temperature for 36 h. Then wash by centrifugation, the washing condition is 12000rpm, 20min, repeated 8 times. These precipitates were soaked in 50 mL of deionized water, and then sonicated at 1000 W for 3 h. Washed 5 times by a 1:1 mixture of water and ethanol, freeze-dried to obtain the final Nb 2 C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com